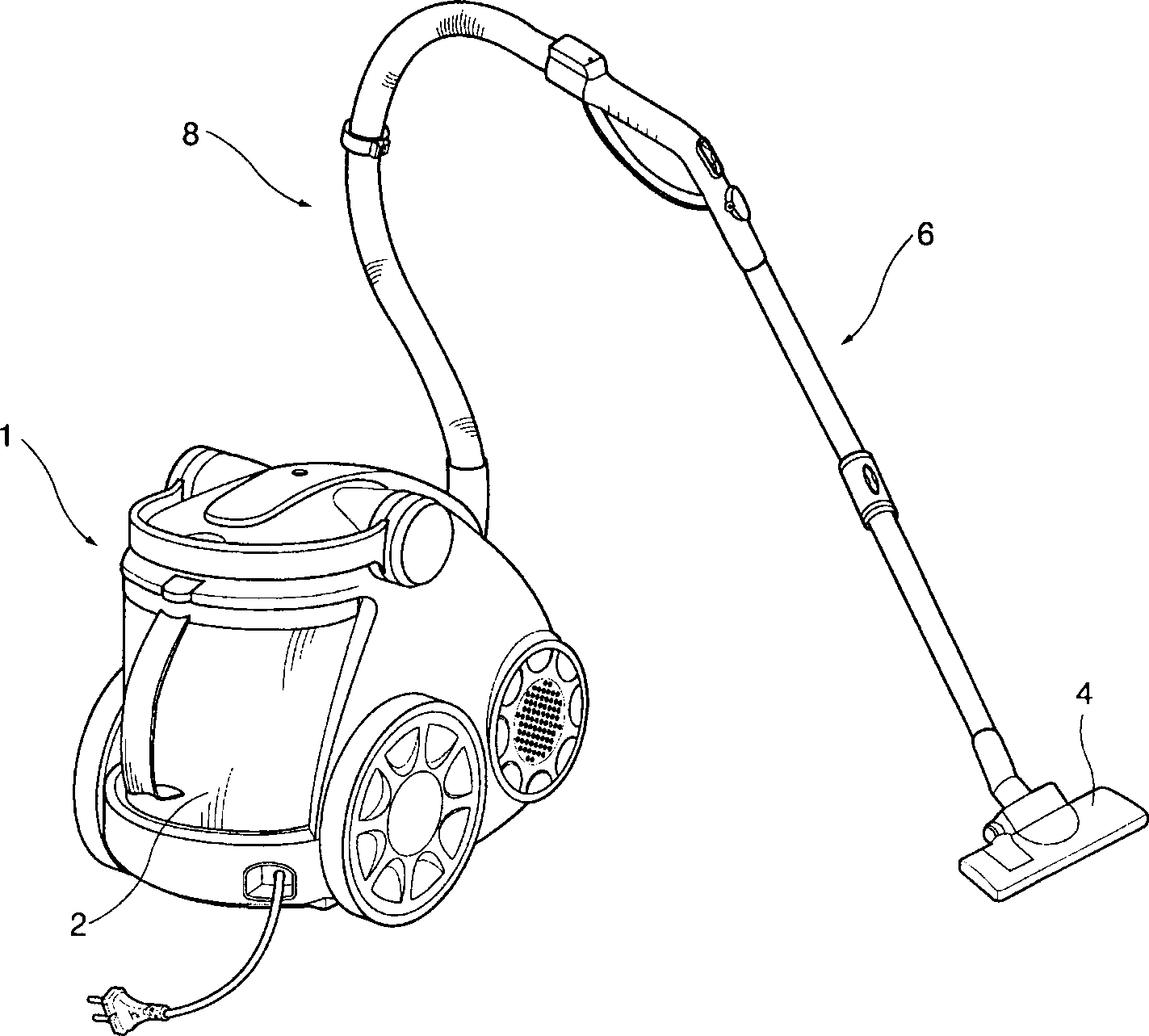

Dust collector box of vacuum cleaner

A technology for vacuum cleaners and dust collection boxes, applied in vacuum cleaners, suction filters, applications, etc., can solve the problems of suction loss, influence, and increase the number of parts, and achieve the effects of supporting suction loss, simplifying the internal structure, and improving suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

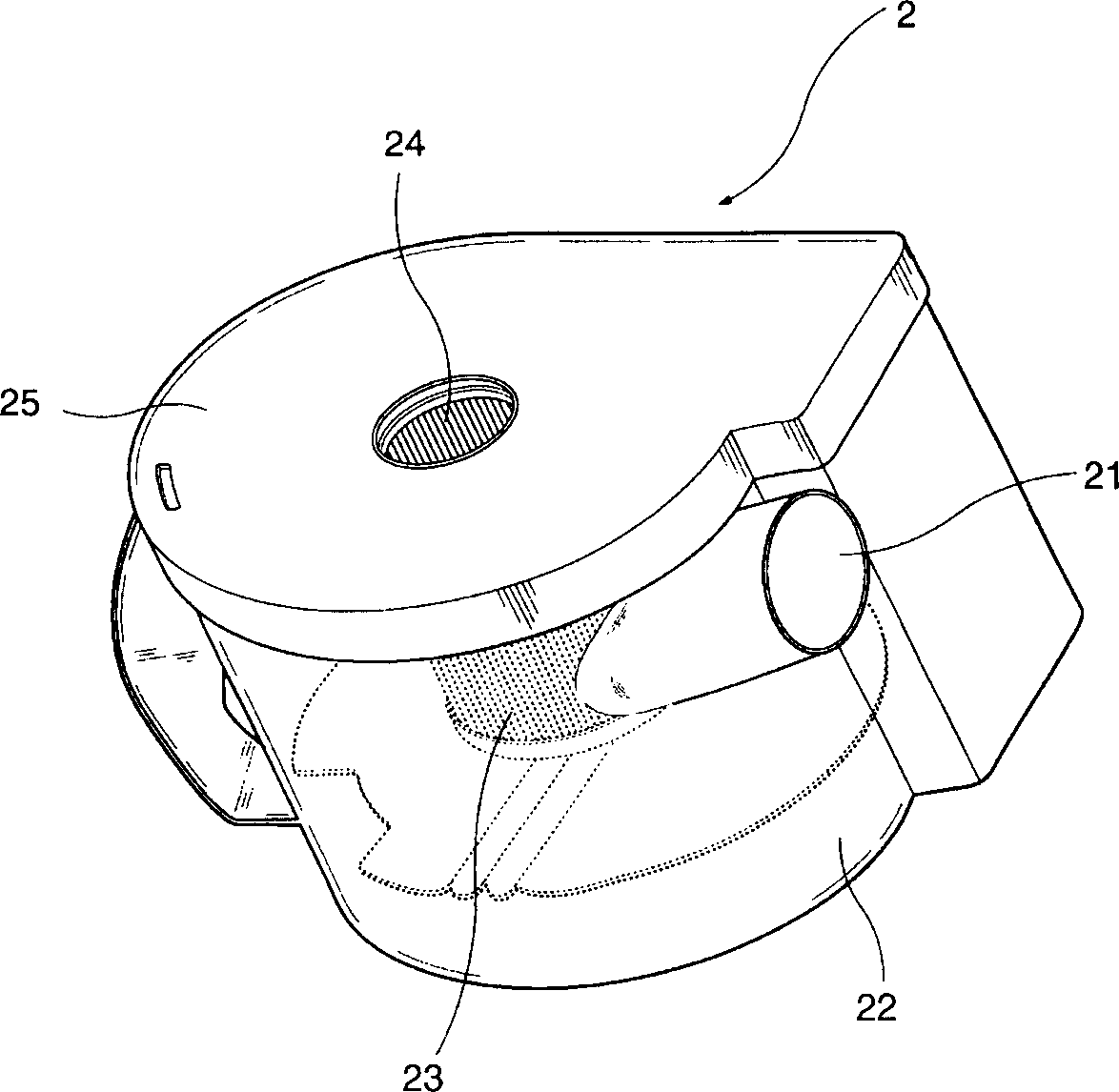

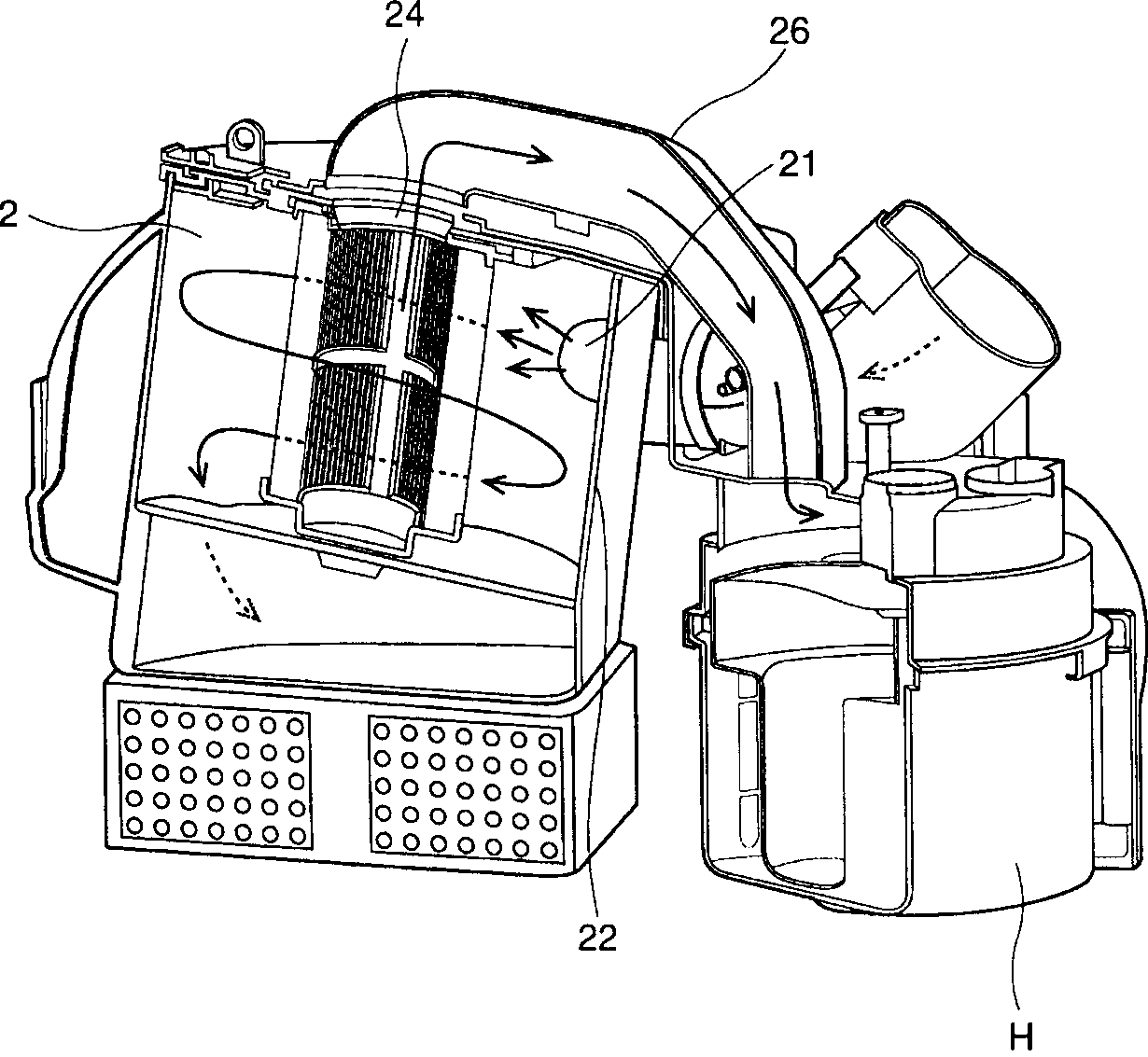

[0016] Such as Figure 4 , Figure 6 As shown, the dust collection box 100 for a vacuum cleaner of the present invention is mainly composed of a box body 130 and a box cover 110 that opens and closes the box body 130. The box 130 is a cylindrical shape with an open upper end, and an air inlet 134 is provided on the upper part. The direction of the air inlet 134 is consistent with the tangential direction of the inner surface of the box 130. The air sucked in through the inlet 134 will form a vortex in the box 130. The box cover 110 is installed on the upper mouth of the box body 130 and used for opening and closing the box body 130. A detachable filter 114 is installed in the center of the lower part, and a handle 116 for grasping is provided on the box cover 110 to facilitate the separation of the dust box 100 from the main body of the vacuum cleaner. The handle can also be provided on the side of the box 130. The filter 114 has a hollow cylindrical shape and is used to filter fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com