Stirring heat transfer device

A stirring plate, hollow shaft technology, applied in indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve problems such as wear, water leakage, cracks or openings at the bottom of the shell, and achieve the effect of prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

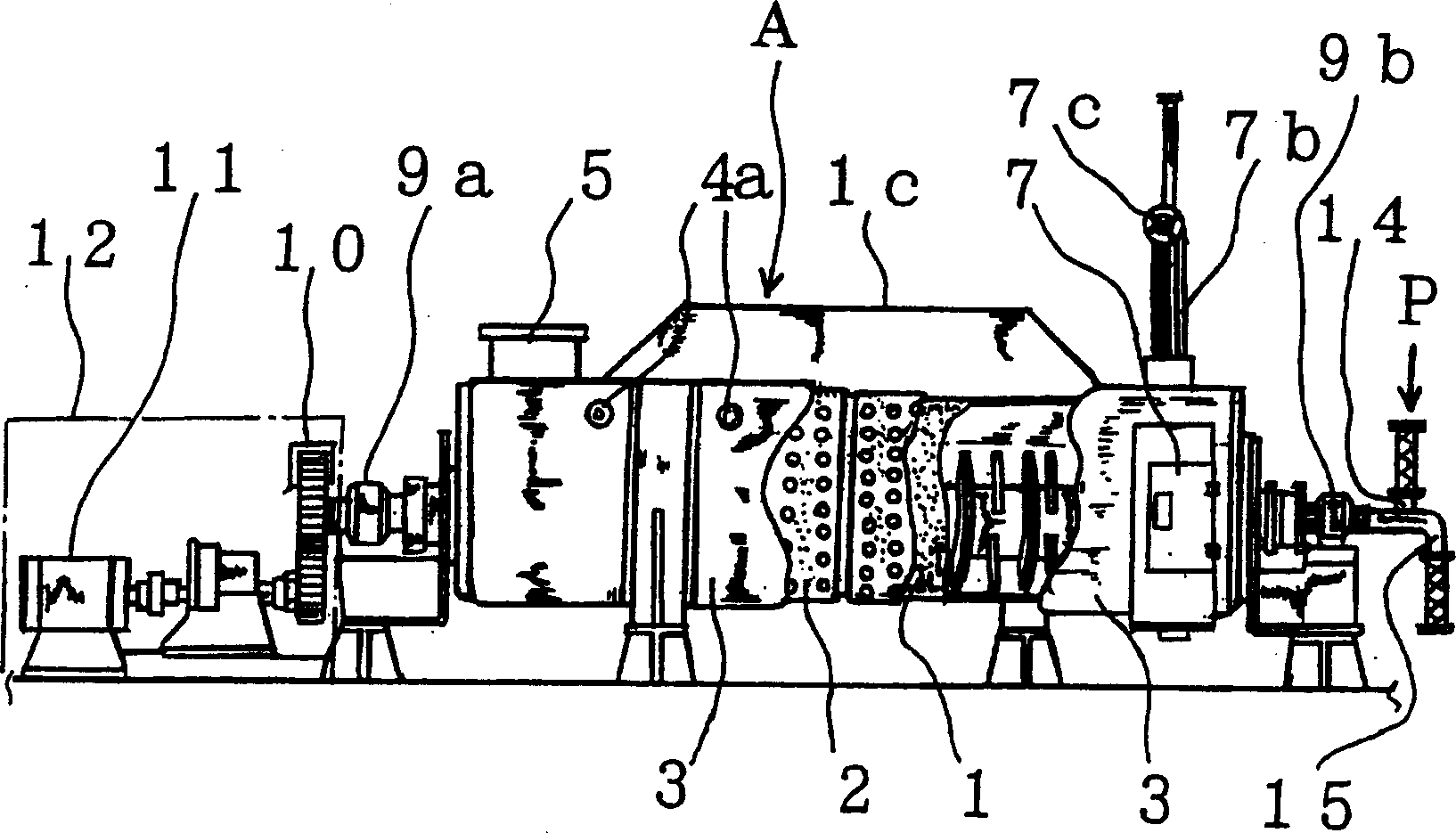

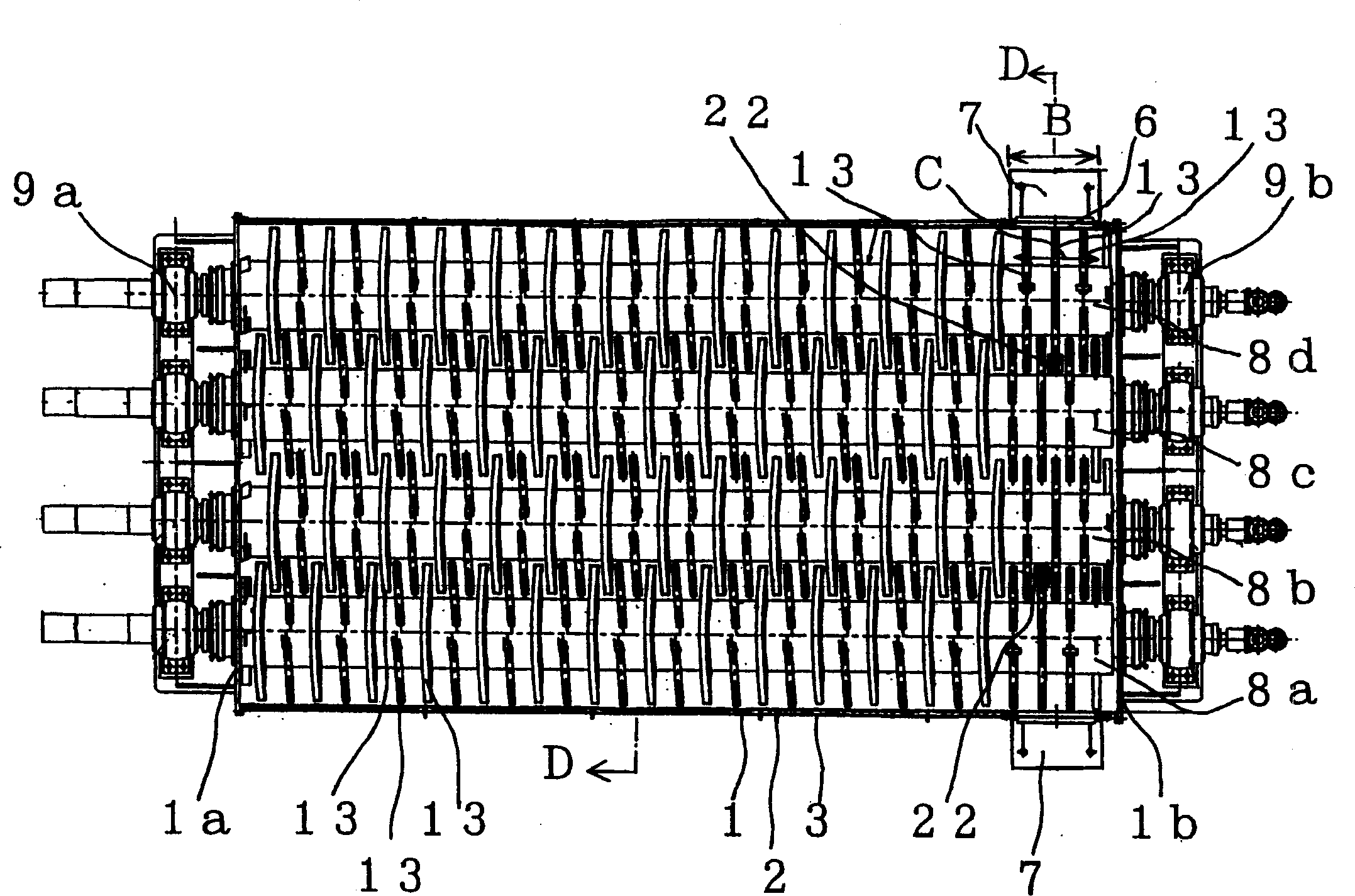

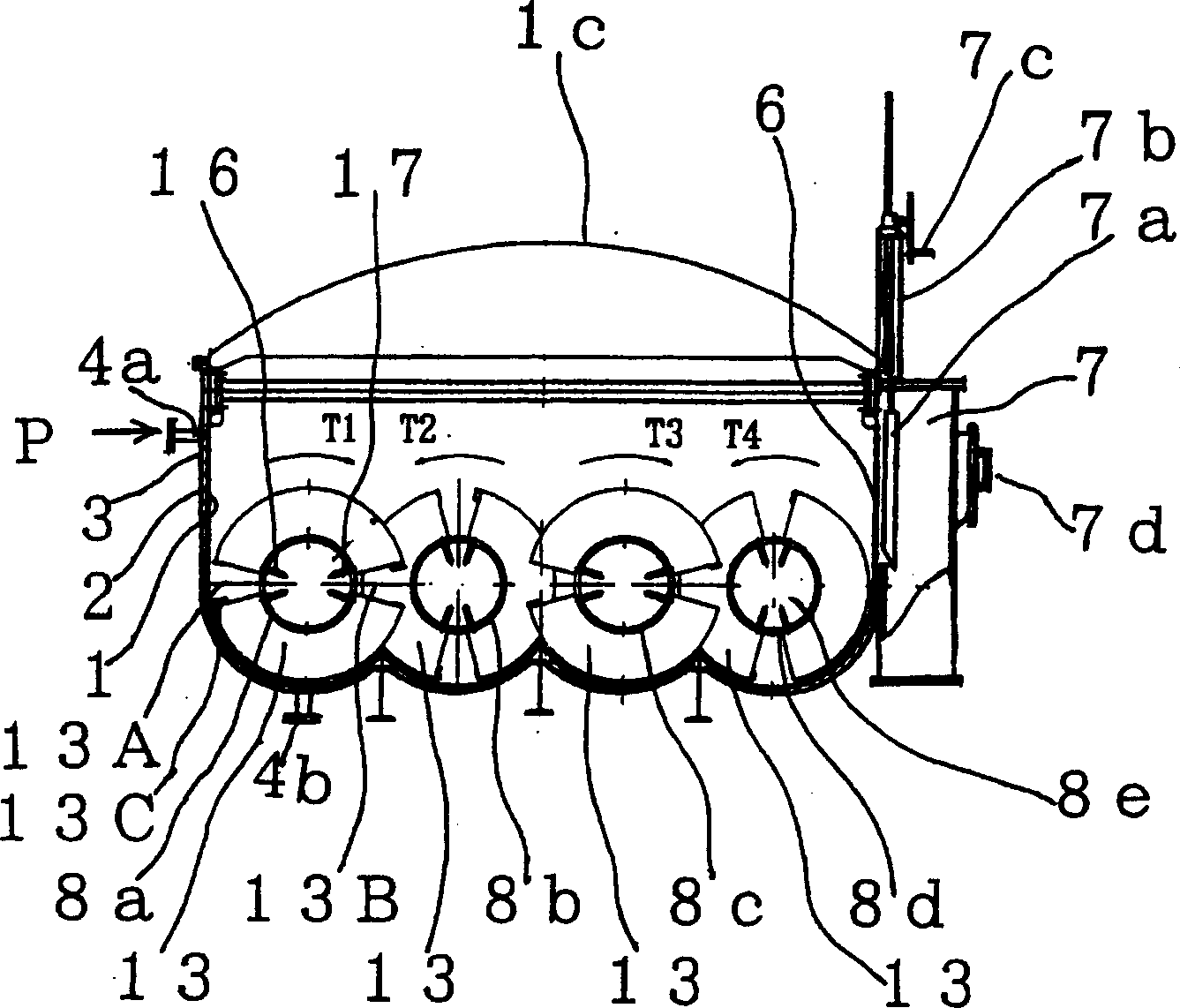

[0022] Figure 1 ~ Figure 4 It is a figure which shows Example 1 of the stirring heat transfer apparatus of this invention, and this is demonstrated.

[0023] In this embodiment, A is a stirring heat transfer device, which is provided with an upper cover 1c and a casing 1. On the outer periphery of the casing 1, for example, water jackets 2 such as indented flat water jackets are provided in multiple axial directions. The outer periphery of the water jacket 2 constitutes an outer casing 3, and the outer casing 3 is provided with the heat exchange medium inlet 4a to the side of the water jacket, so that as figure 1 and image 3 The shown heat exchange medium P is flowable. And the heat exchange medium P is discharged from the heat exchange medium outlet 4b on the side of the water jacket. Additionally, if image 3 As shown, the bottoms of the casing 1, the water jacket 2, and the outer casing 3 are waved so as to surround four stirring plates 13 described later. The housin...

Embodiment 2

[0041] Embodiment 2 of the stirring heat transfer device of the present invention exemplifies a technology in which relatively large rake blades are provided at the front end of the stirring plate arranged substantially perpendicular to the axis of the hollow shaft shown in Embodiment 1.

[0042] The larger rake blade 22, in figure 2 The middle represents on the hollow shaft 8a, 8d, in Figure 4 (a) means it is on 8b. The larger rake blades 22 have a certain width in the horizontal or vertical direction as described later, and are characterized by increasing the rake area of the processed material or dry matter, etc., and are arranged on the row. The hollow shafts 8a to 8d near the feed port 7 are arranged in the axial direction of the bearing portions of the hollow shafts 8a to 8d, that is, on the hollow stirring plate 13 arranged in a direction substantially perpendicular to the length of the hollow shafts, thereby exerting its effect. That is, after stirring, heat-tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com