Pipe for cable laying and producing method thereof

A technology of cable laying and manufacturing methods, which is applied in the direction of cable laying equipment, cable installation, pipeline laying and maintenance, etc., and can solve problems such as cable twisting, complex structure, and pipe misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

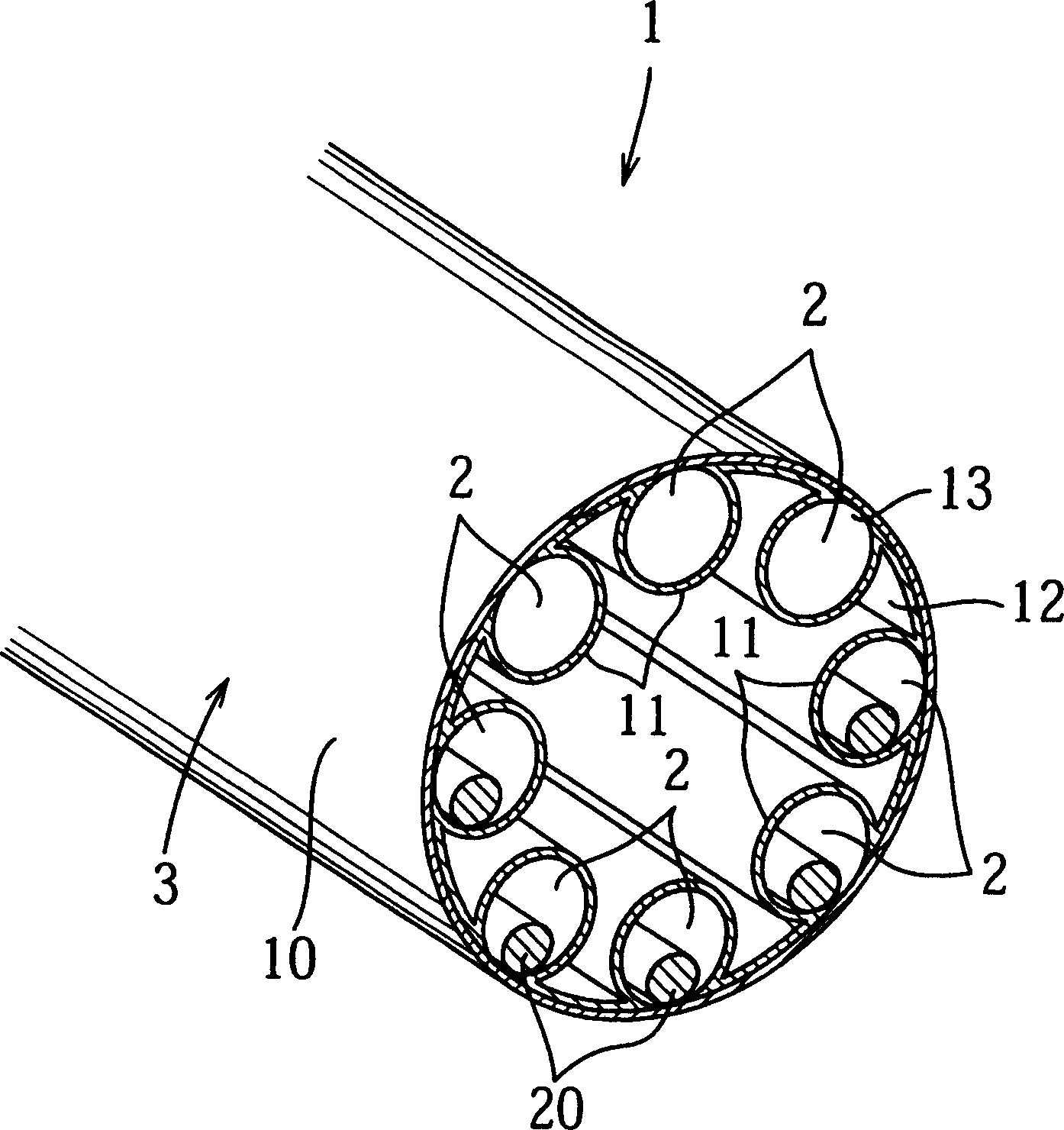

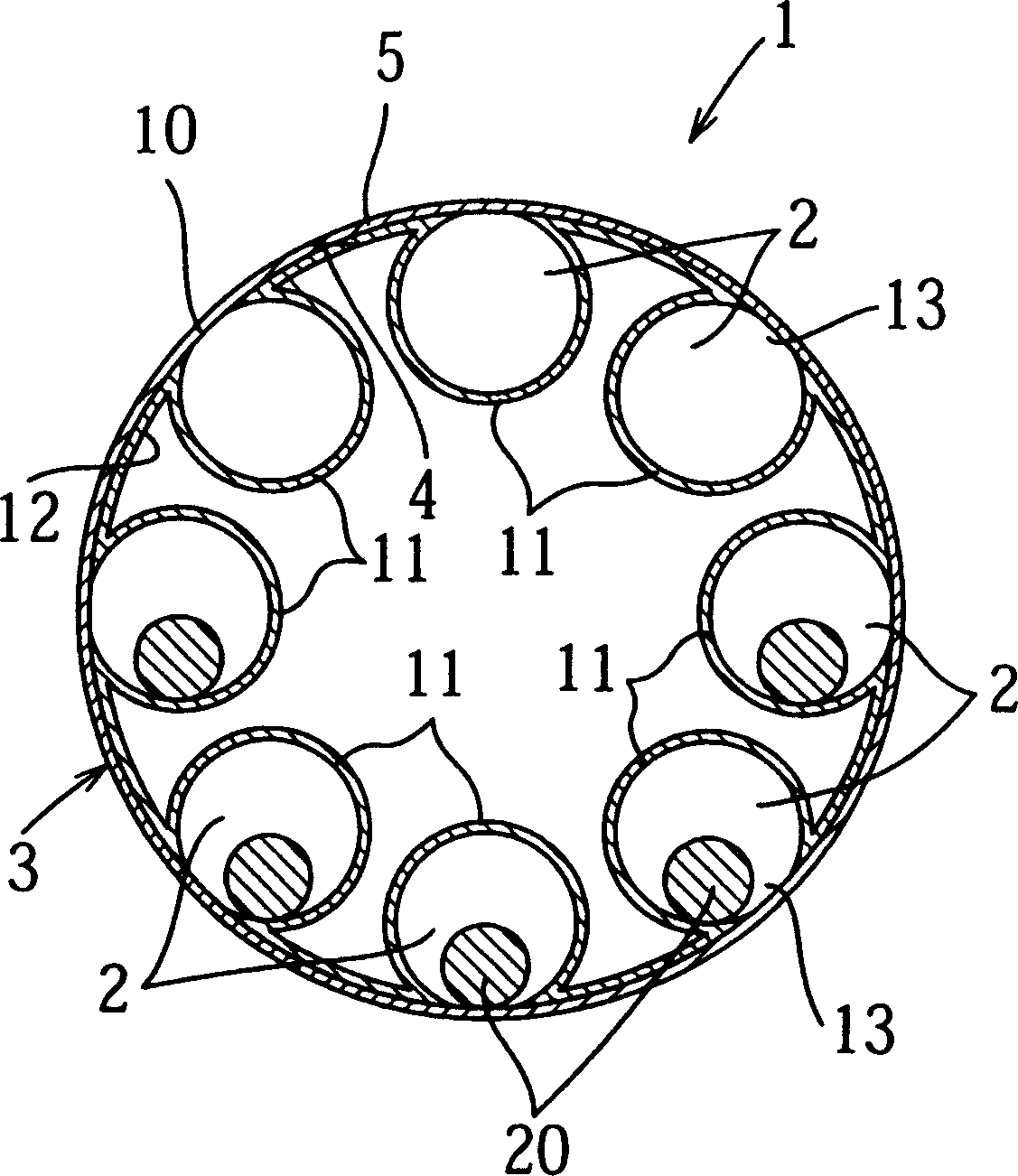

[0021] The following is a detailed description of the drawings of specific embodiments of the present invention, and the cable laying pipe 1 related to specific embodiments of the present invention is as follows: figure 1 and figure 2 As shown, a plurality of cable insertion passages 2, 2 that are substantially parallel to each other are integrally formed as a flexible pipe wall component.

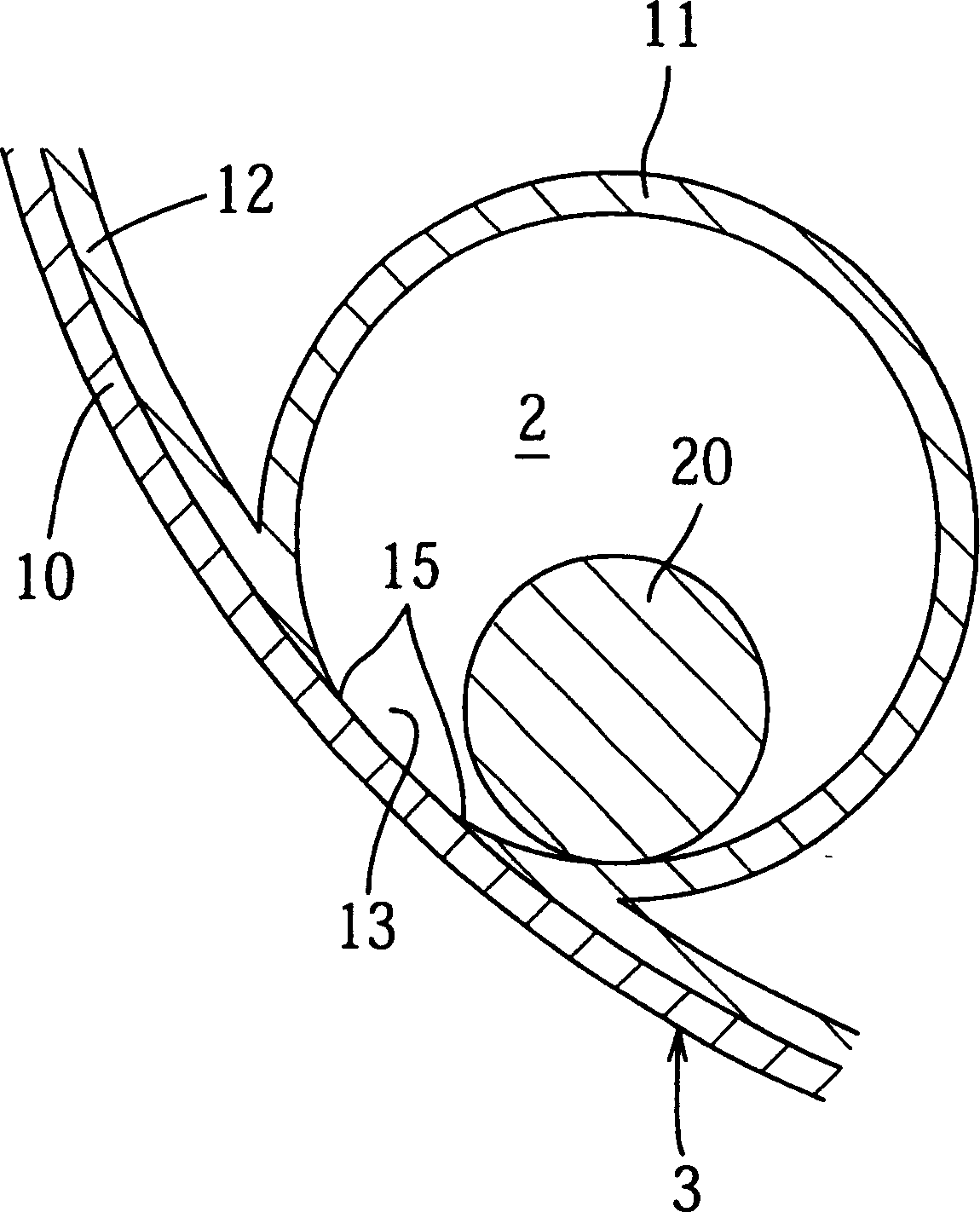

[0022] Tube wall components 3 such as Figure 4 Shown, is to be made by synthetic resin materials such as polyethylene, has the outer tube material 10 of bendability, slightly band shape and is also made of synthetic resin materials such as polyethylene, has mutually slightly The inner tube material 12 is composed of a plurality of parallel protrusions 11 , 11 .

[0023] In order not to allow the protrusions 11, 11 of the inner tube material 12 to interfere with each other, they are arranged at equal intervals, and each protrusion 11, 11 is formed in a ring shape, and the roots of these...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com