Blowing machine motor

A blower and motor technology, applied in the installation of motor fan components, electromechanical devices, mechanical equipment, etc., can solve problems such as obstruction, low blower operating efficiency, and loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

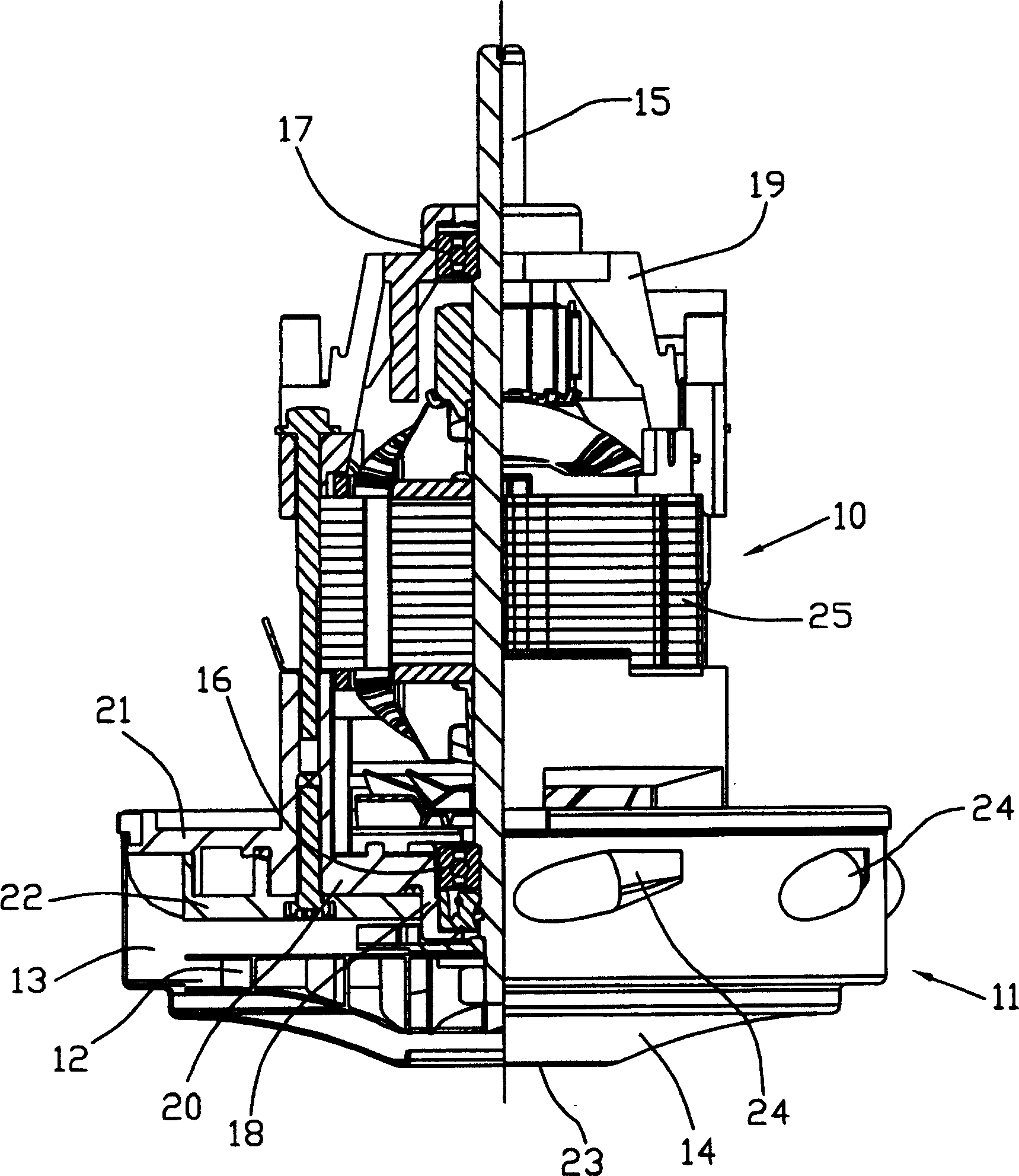

[0013] figure 1 A partial cutaway view showing the bypass duct blower motor assembly. The assembly has a motor section 10 and a blower section 11 . The motor section includes a general purpose motor. The operation of this motor is well known and will not be described.

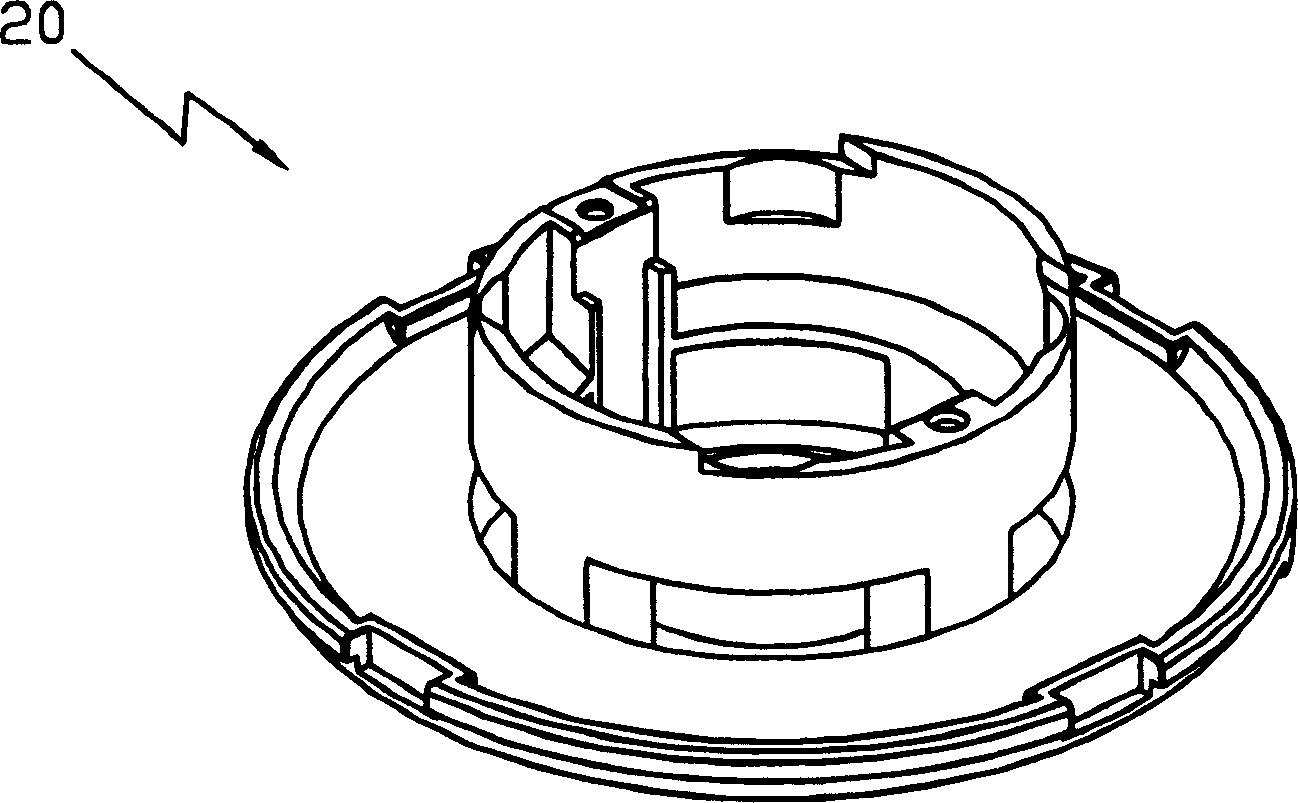

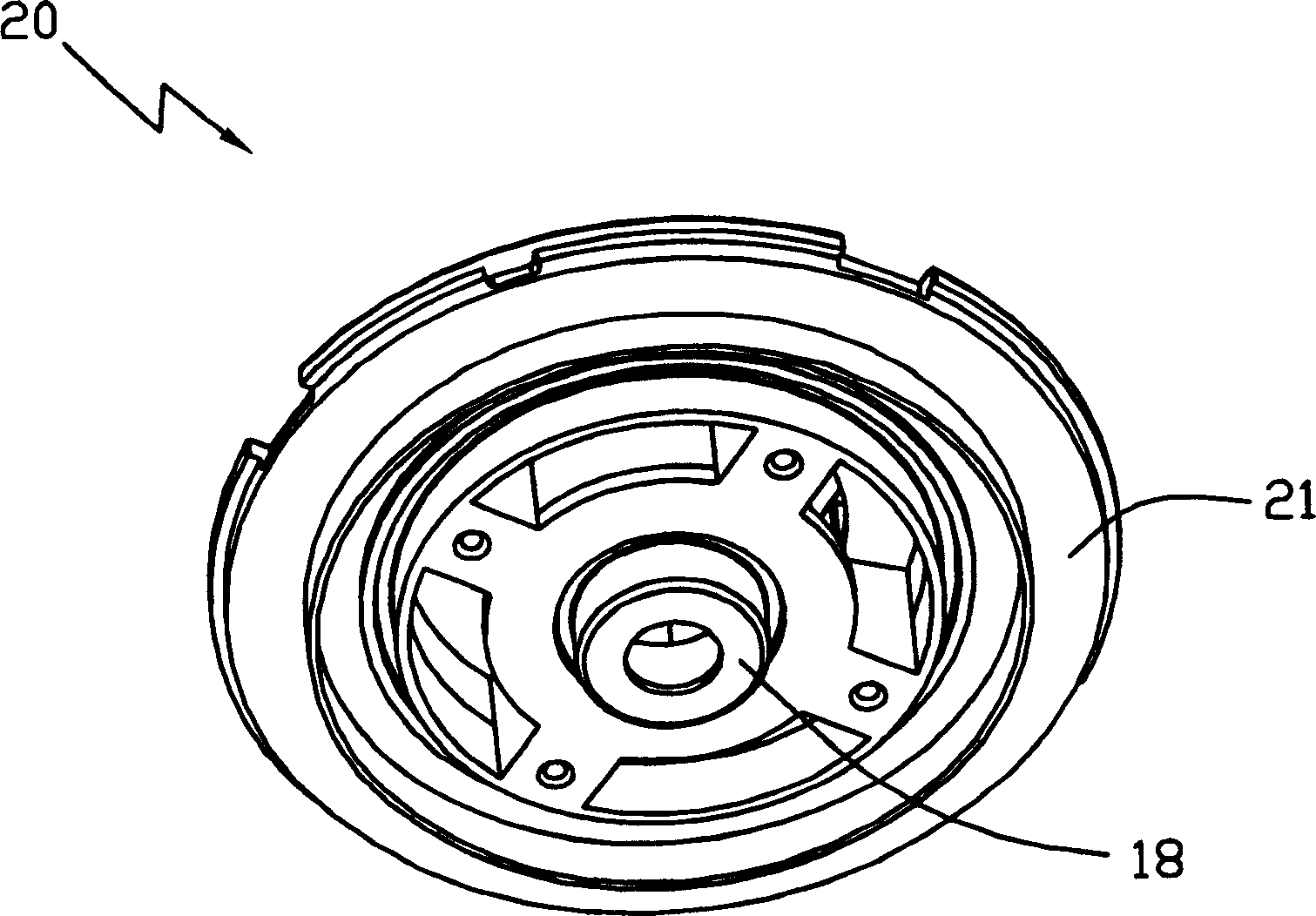

[0014] The blower section 11 includes a centrifugal fan-type impeller 12 located in an impeller chamber 13 defined by an elongated cup-shaped impeller case 14 having a bottom wall and a peripheral wall, and two Or combined with a flange 21 of a fan end bracket 20 of the motor. The fan end bracket 20 separates the blower section 11 from the motor section 10 and closes the open end of the impeller case 14 . The impeller box 14 has a single central inlet 23 in its bottom wall and a plurality of outlets 24 in its peripheral wall.

[0015] The universal motor has a shaft 15 mounted on bearings 16 and 17 . The bearing 17 is installed on a boss 18 in the fan end bracket 20 , and the bearing 17 is installed on an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com