Patterned scarf, method and loom for producing the same

A technology for scarves and looms, applied in the directions of scarves, looms, multi-looms, etc., can solve the problems of low warp density and weft density, rough patterns, and inability to distinguish each scarf, achieve efficient production, improve durability and The effect of feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

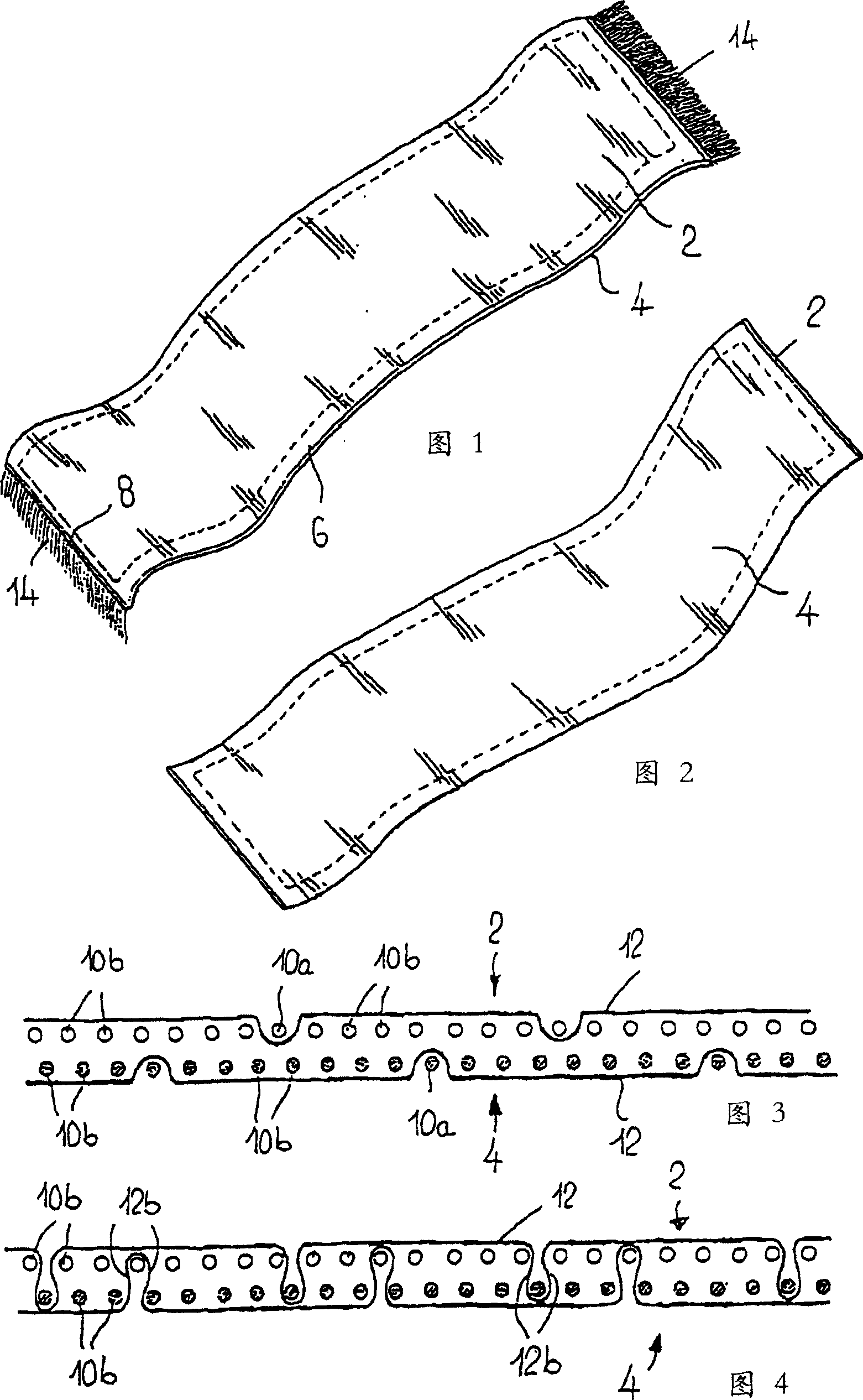

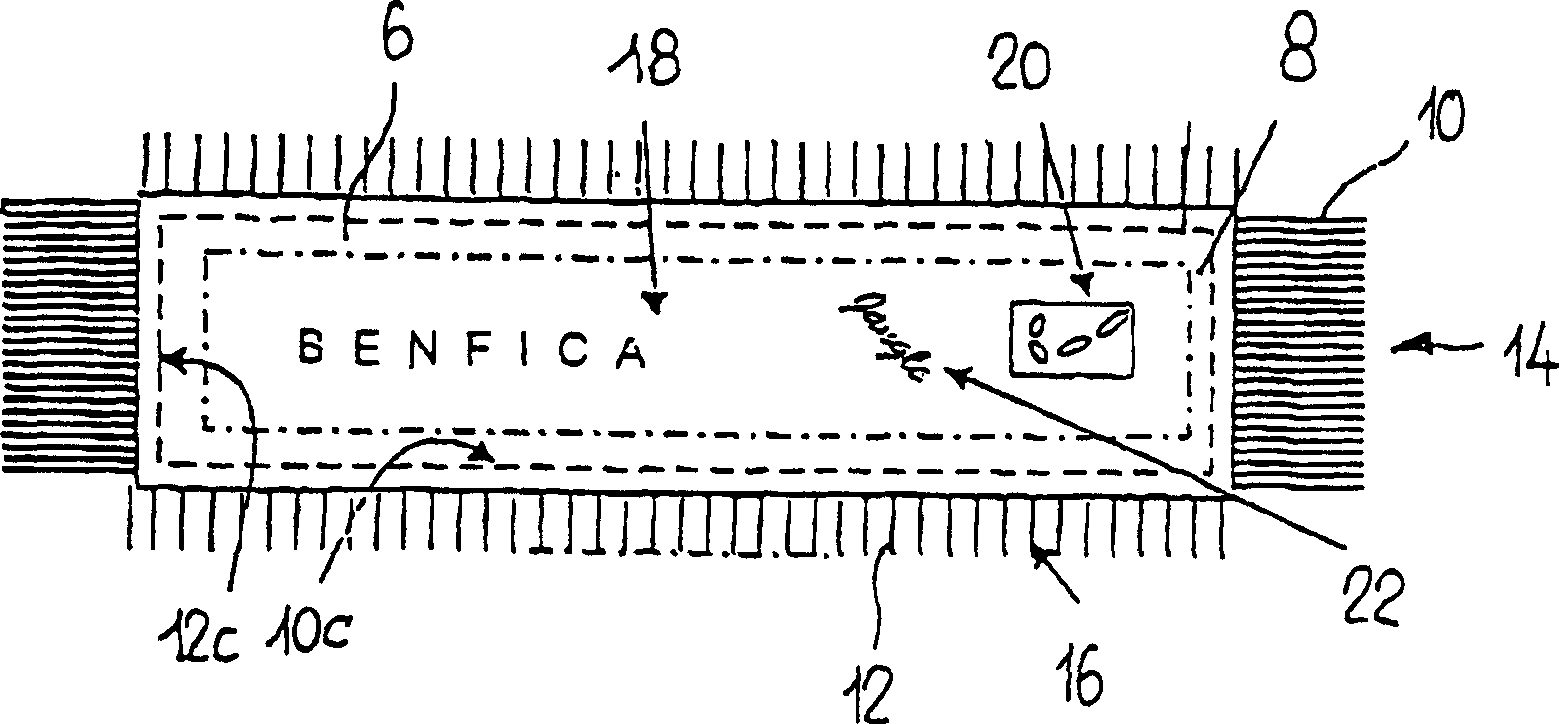

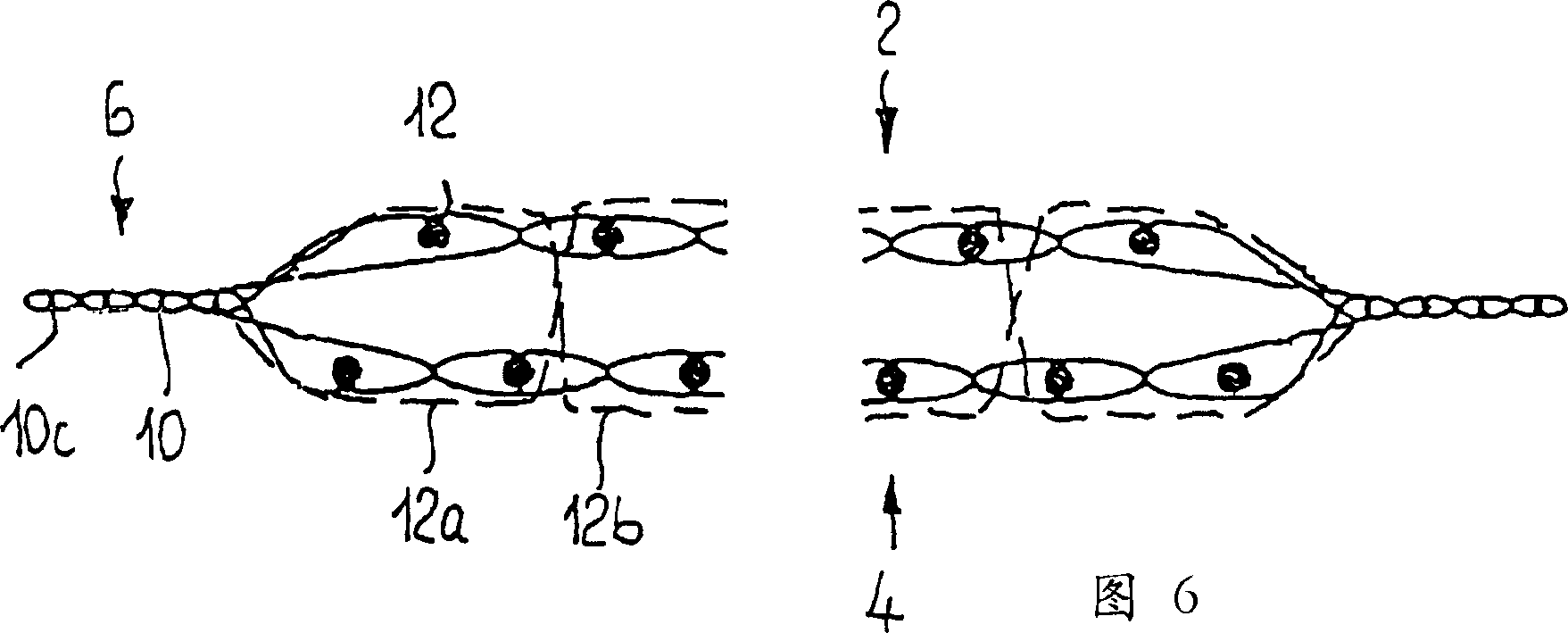

[0035] Figures 1 to 4 illustrate the prior art related to and on which the present invention is based. The scarf shown in the figure comprises a first fabric layer 2 and a second fabric layer 4 interwoven along longitudinal edges 6 and transverse edges 8, thereby forming a fully enclosed cylinder. Each fabric layer 2, 4 is formed of monochromatic warp yarns 10 and multicolored weft yarns 12, which warp yarns are independent of the color to be produced on the scarf. As can be deduced from FIG. 3 , the weft threads 12 are inserted at intervals between the warp threads 10 , that is, the weft threads intersect with the particular warp threads 10 a only in the case of the particular warp threads 10 a , while the warp threads 10 b located between the particular warp threads 10 a In the case of the warp yarn 10b, it covers the warp yarn 10b and enters the area above the warp yarn to be patterned. The weave pattern of the weft yarns is at least one warp yarn from weft yarn to weft ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com