Shadow mask frame of cathode ray tube

A technology for cathode ray tubes and shadow masks, which is applied in the direction of cathode ray tubes/electron beam tubes, discharge tubes, electrode devices and related components, and can solve the problems of deterioration of microphonic characteristics and drop characteristics of shadow masks 8, reduction of bonding force, Panel 1 scratches and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiment of the shadow mask frame of the cathode ray tube made according to the present invention with reference to the accompanying drawings

[0031] Embodiments will be described.

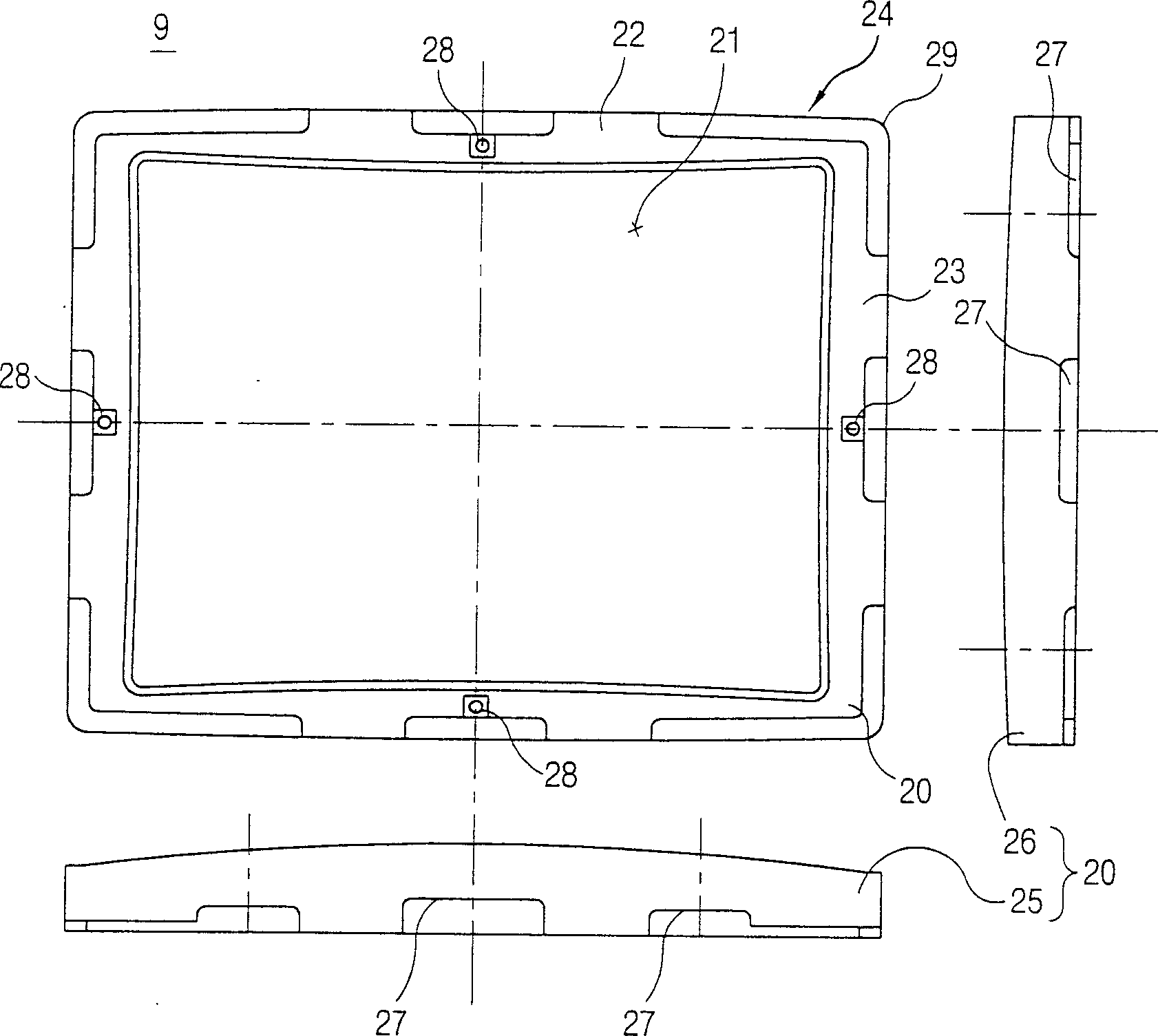

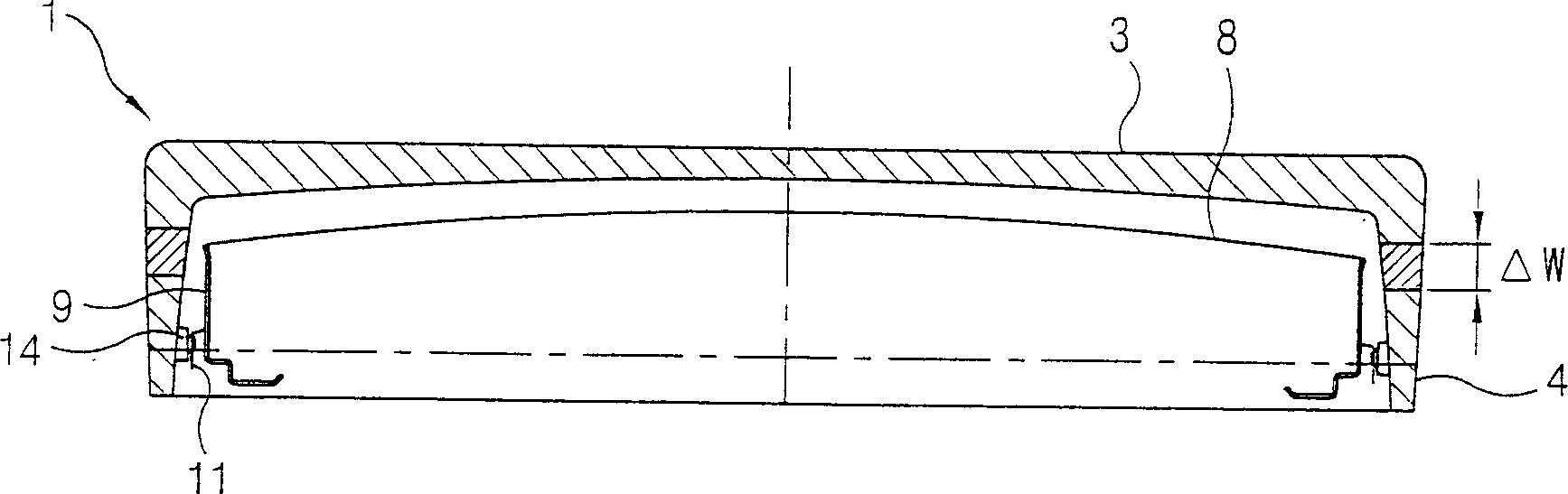

[0032] Figure 4 is a schematic diagram of a cathode ray tube made in accordance with the present invention, Figure 5 is an expanded view of the shadow mask frame of the cathode ray tube made according to the present invention;

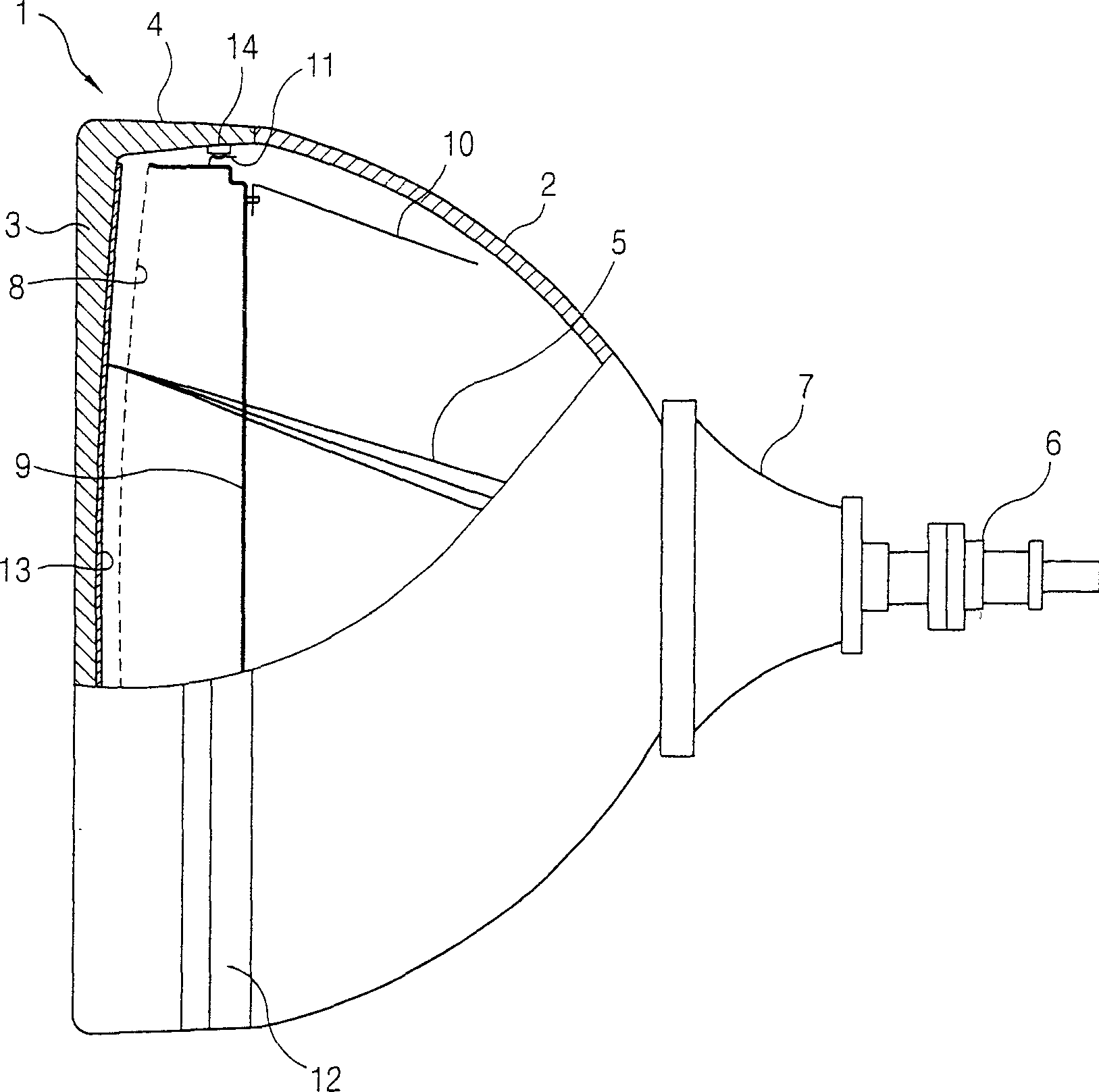

[0033] Such as Figure 4 As shown, in the cathode ray tube made according to the present invention, the panel 101 as the front glass and the funnel 102 as the rear glass are combined, and the inner space is sealed in a high vacuum state.

[0034] Moreover, the cathode ray tube includes a fluorescent surface 113 covering the inner surface of the panel 101 to perform a certain light emitting function; an electron gun 106 installed at the end of the funnel tube 102 to emit electron beams 105; a deflection coil 107, the Coils are installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com