Split container for making beverage by granular material with the help of water

A split, granular technology, applied in beverage preparation devices, applications, kitchen utensils, etc., can solve problems such as hindering boiling water, polluting coffee machines, and working hard for coffee machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

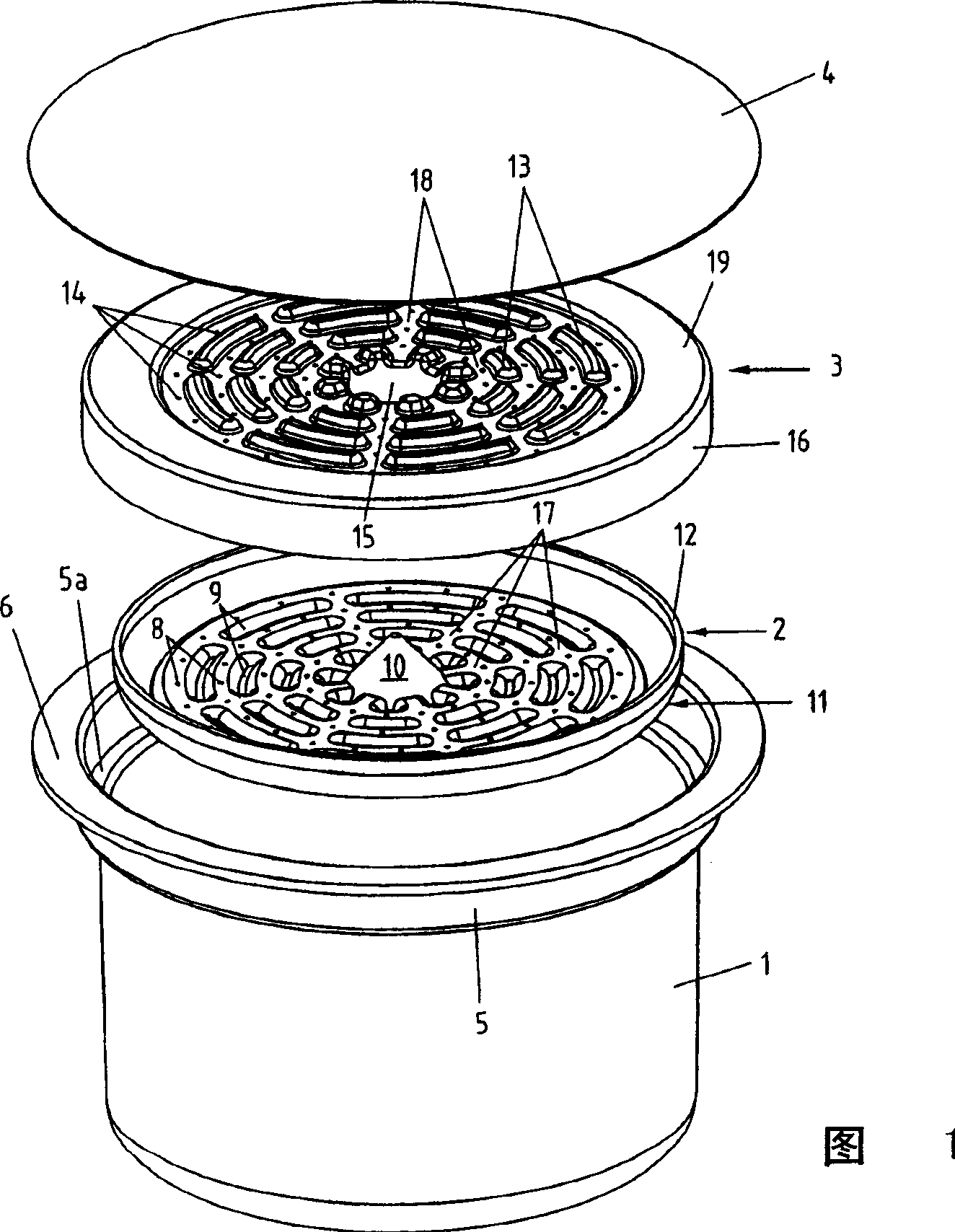

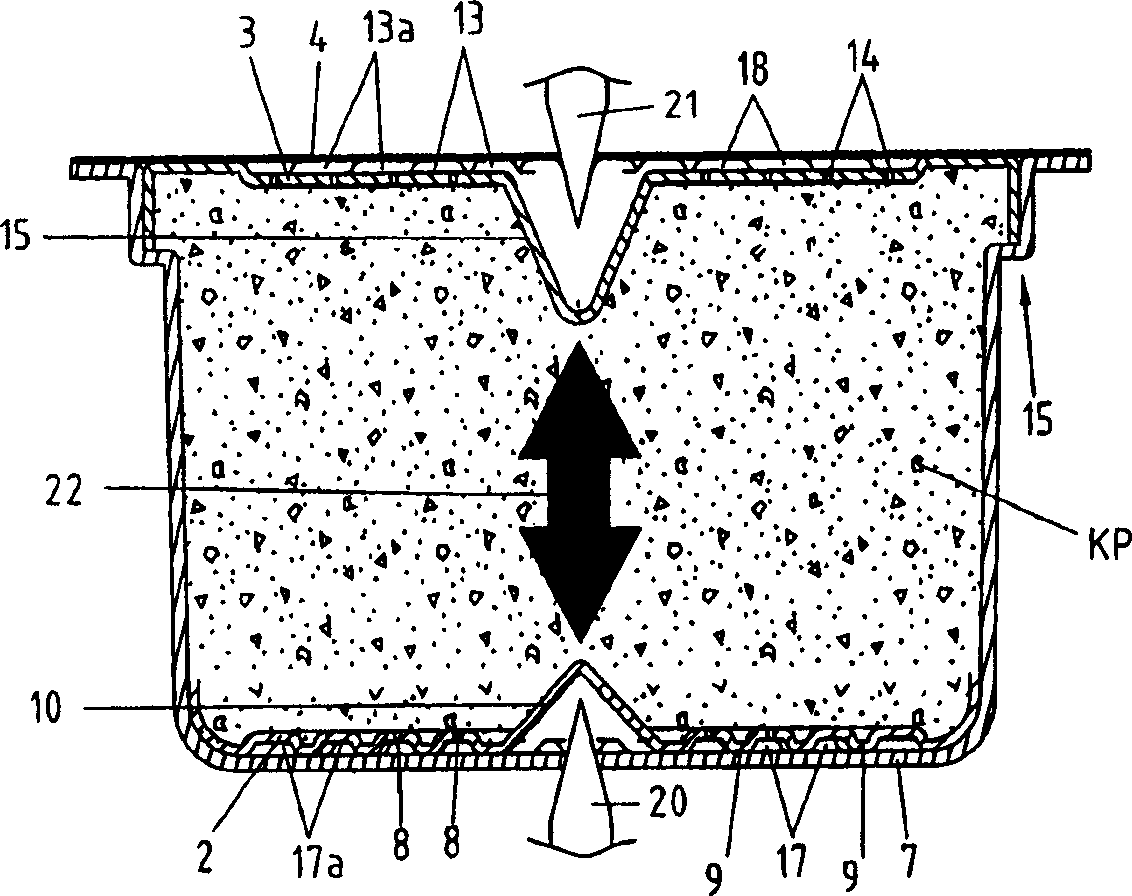

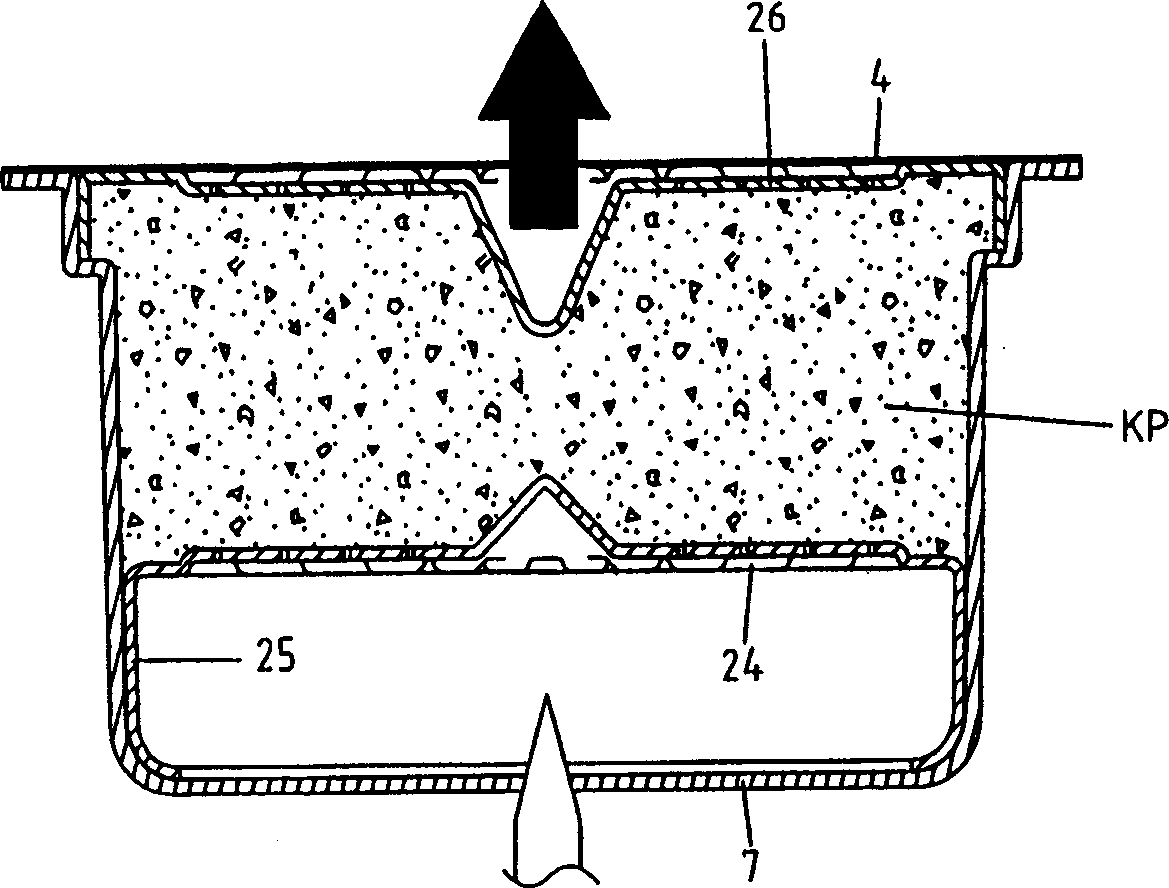

[0025] The basic structure of the split container will be further explained with the help of the exploded view according to FIG. 1. Although this type of split container can contain fundamentally different substances that can be extracted with the aid of water for making beverages, the following only refers to the split container with coffee powder to make regular coffee or espresso. Viewed from bottom to top, the split container is composed of a bucket 1, a lower collecting element 2, an upper distributing element 3, and a lid 4. The coffee powder to be contained in the barrel 1 between the collecting element 2 and the dispensing element 3 is not visible in the drawing. Not only the barrel 1 but also the lid 4 is composed of an airtight multilayer connecting film. The collecting element 2 and the distributing element 3 are basically designed in a disk shape and are preferably manufactured by deep drawing.

[0026] The barrel 1 which is slightly expanded in an upward conical shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com