Electronic device for supplying power source and noise filter which having high-efficient noise reducing

A technology of electronic devices and filters, applied in circuit devices, reduction of crosstalk/noise/electromagnetic interference (, electric solid-state devices, etc.), can solve problems such as impedance rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

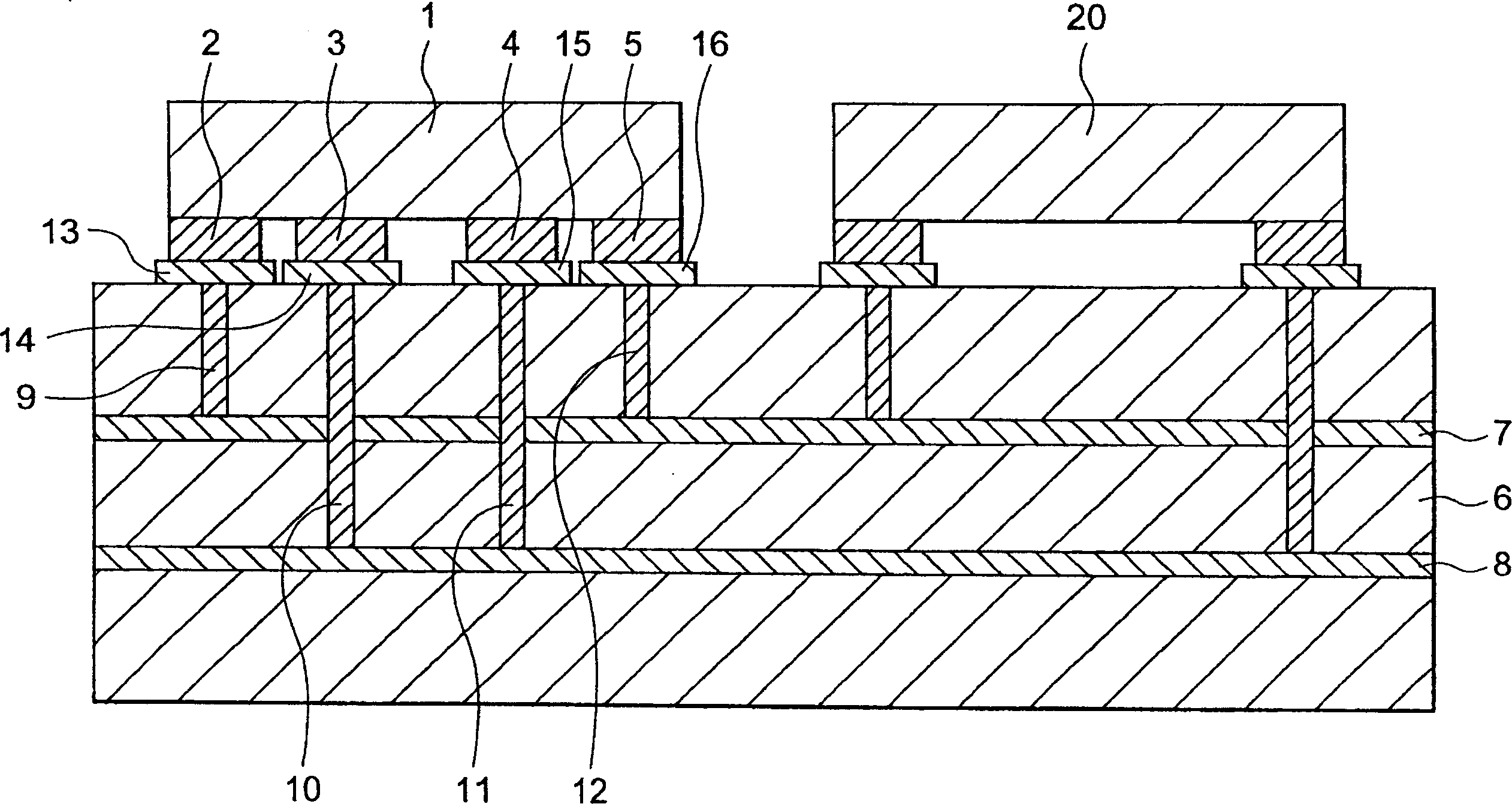

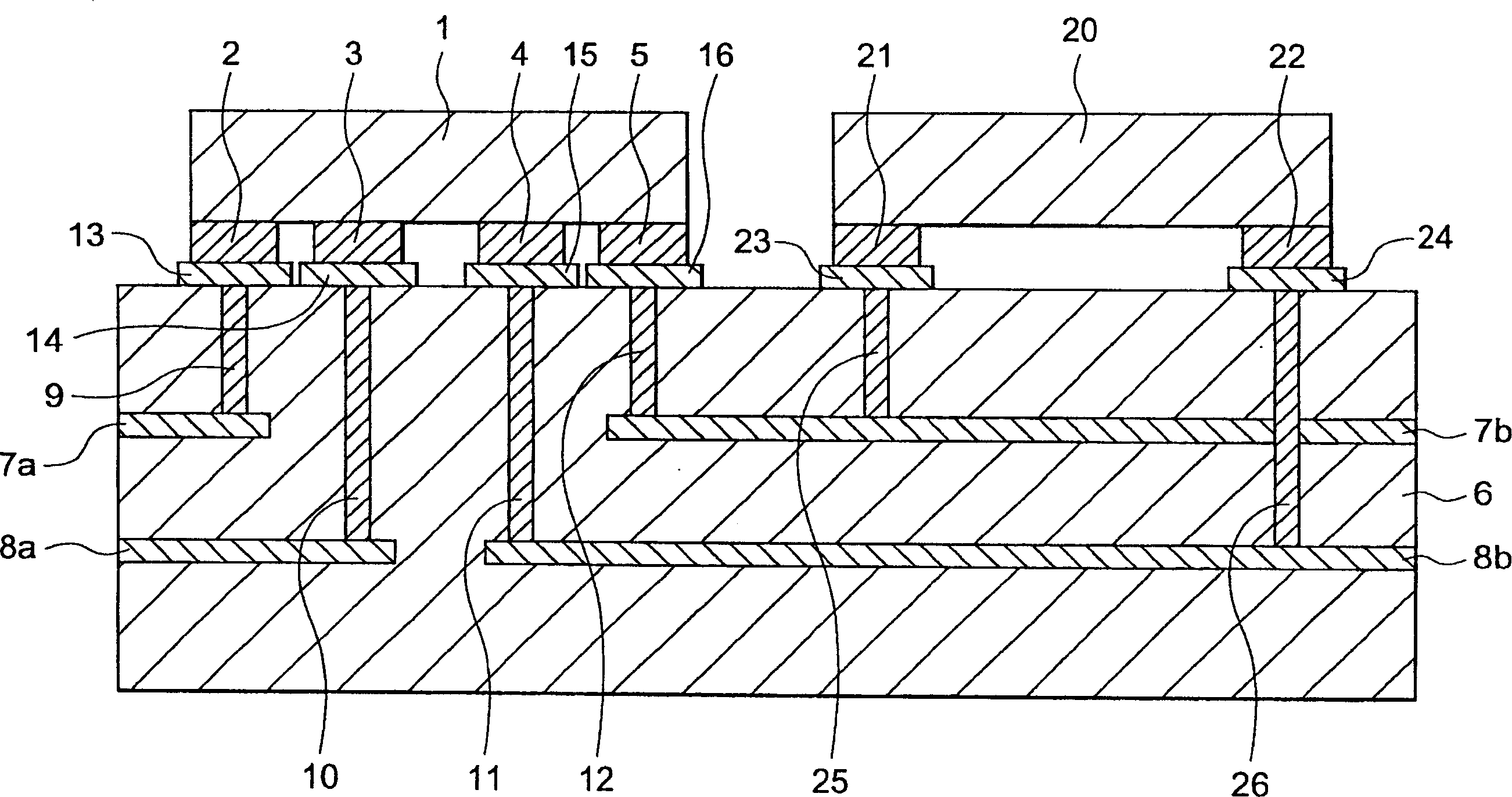

[0049] see image 3 , an electronic device includes a circuit board 6 and a noise filter 1 fixed on the circuit board. In this embodiment, a load circuit 20 such as an LSI chip is also mounted on the circuit board 6 .

[0050] The noise filter 1 has power and ground input terminals 2 and 3 and power and ground output terminals 5 and 4 .

[0051] The circuit board 6 has on its surface first to fourth conductor regions 13-16 connected to the power and ground input terminals 2 and 3 and the power and ground output terminals 5 and 4 of the noise filter 1, respectively. The circuit board 6 has a power line conductor layer (VCC layer) 7 a and a ground layer (GND layer) 8 a as independent internal conductive layers inside the circuit board 6 . The VCC layer 7a and the GND layer 8a extend to below the first and second conductor regions 13 and 14 respectively, and are connected to the first and second conductor regions through the first and second through holes 9 and 10, in the circu...

no. 2 example

[0059] see Figure 4 , except that will be in image 3 The electronic device shown is similar to the first embodiment, except that the ground input and output terminals 3 and 4 are connected together to form a single ground terminal indicated only by reference numeral 3.

[0060] In this embodiment, those skilled in the art can understand that the Figure 4 electronics in the image 3 The embodiment shown in works in the same way.

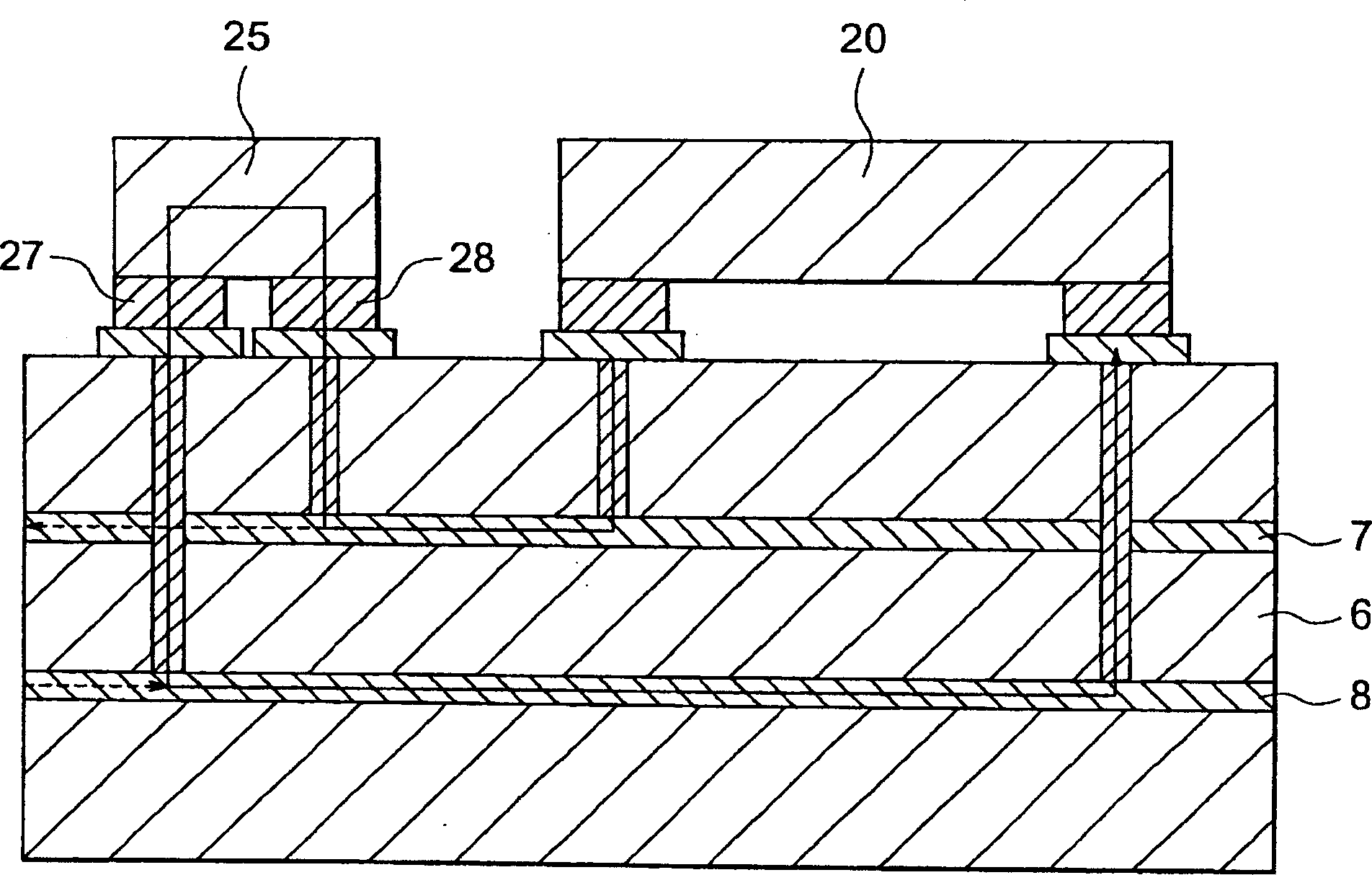

no. 3 example

[0062] see Figure 5 , the electronic device according to the third embodiment shown here is an LSI chip 20 fixed on another circuit board 17 with a DC power supply. Another circuit board 17 has conductor areas 27 and 28 for receiving power supply terminals and ground terminals 21 and 22 of the LSI chip 20 mounted and connected to the circuit board 17 . On the other surface of the circuit board 17 there are further conductor areas 30 and 29 which are connected to the conductor areas 27 and 28 respectively.

[0063] In this embodiment, the circuit board 6 does not make the power supply conductor 7b and the ground conductor 8b the inner layer of the 0-VCC and 0-GND layers, but makes them such as 0-VCC pin 19 and 0-GND pin 18 conductive pins. The 0-VCC pin and the 0-GND pin are located above the fourth and third conductor regions 16 and 15 .

[0064] The 0-VCC pin 19 and the 0-GND pin 18 are connected to conductor areas 30 and 29 on another circuit board 17 . Therefore, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com