Cement compound pipe with plastic inside lining

A composite pipe and cement technology, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problems of not being easy to be popularized and applied in a large scale, short service life, easy to break, etc., and achieve significant economic and social benefits, improve Anti-leakage ability and anti-geological subsidence ability, avoiding the effect of traffic inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

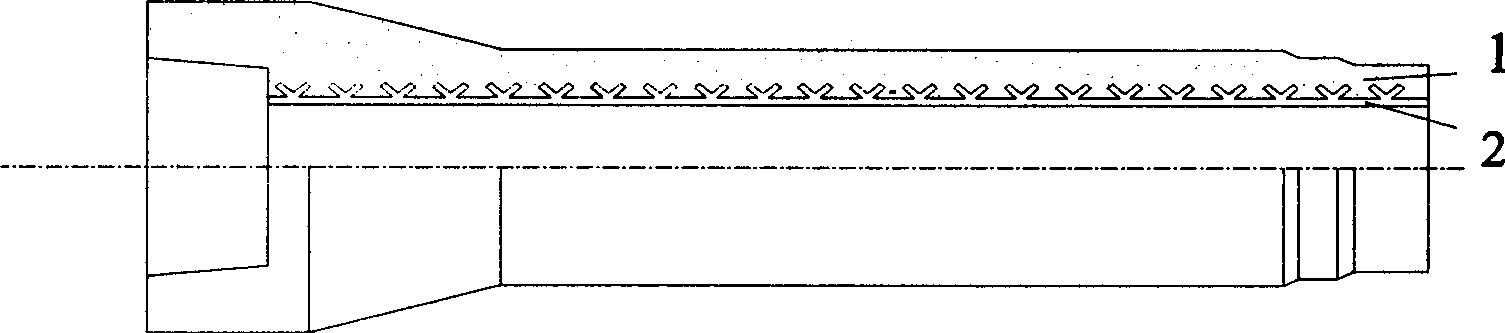

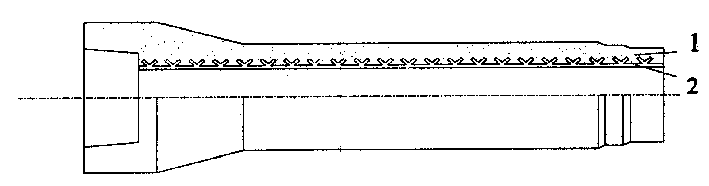

[0017] According to the drawings, the inner diameter of the plastic-lined cement composite pipe is 1350mm, and the total length is 2500mm. The thickness of the inner plastic layer is 2mm, and the material is HDPE. The outer layer is reinforced concrete, with a thickness of 135mm. First extrude the HDPE board, weld it into the inner plastic pipe, and then make the outer reinforced concrete layer according to the reinforced concrete pouring process, and then get the plastic-lined cement composite pipe of the required size, which can be used as an urban underground sewage pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com