Absorption-type refrigerator

An absorption refrigerator and absorption liquid technology, applied in the direction of adsorption machines, refrigerators, refrigeration and liquefaction, etc., can solve many problems, such as corrosion of heat exchangers, and drop in exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

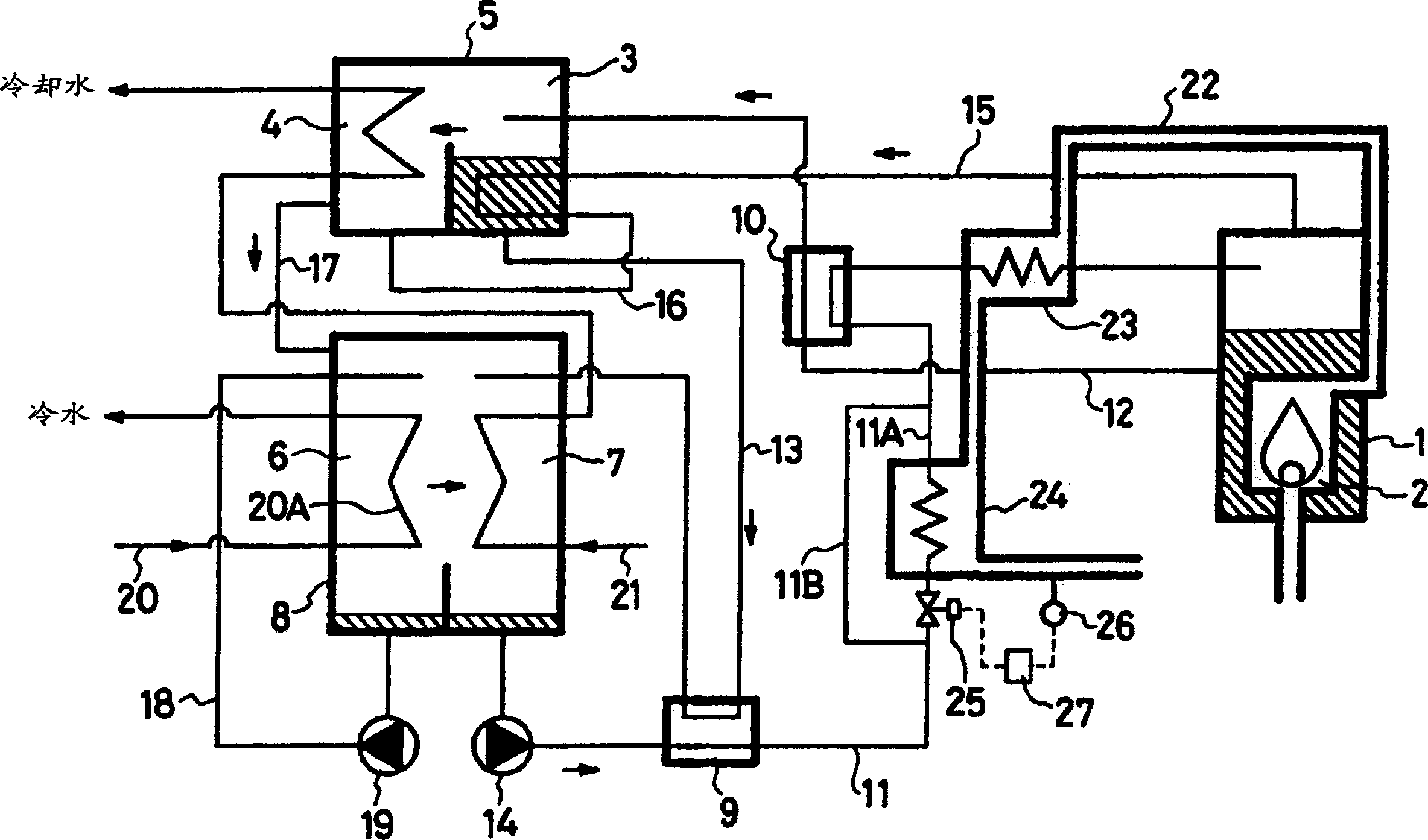

[0016] according to figure 1 A first embodiment of the present invention will be described. 1 is a high-temperature regenerator, which is configured such that the heat of the gas burner 2 using city gas as fuel is used to heat the absorption liquid and evaporate and separate the refrigerant. 3 is a low-temperature regenerator, 4 is a condenser, and 5 is a storage low-temperature regenerator. 3 and the high-temperature shell of the condenser 4, 6 is an evaporator, 7 is an absorber, 8 is a low-temperature shell for accommodating the evaporator 6 and the absorber 7, 9 is a low-temperature heat exchanger, 10 is a high-temperature heat exchanger, 11 ~13 is the absorption liquid pipe, 14 is the absorption liquid pump, 15~18 is the refrigerant pipe, 19 is the refrigerant pump, 20 is the cold water pipe, 21 is the cooling water pipe, 22 is the exhaust gas discharged from the gas burner 2. Air pipe, 23 is a first exhaust gas heat recovery device, 24 is a second exhaust gas heat recov...

no. 2 example

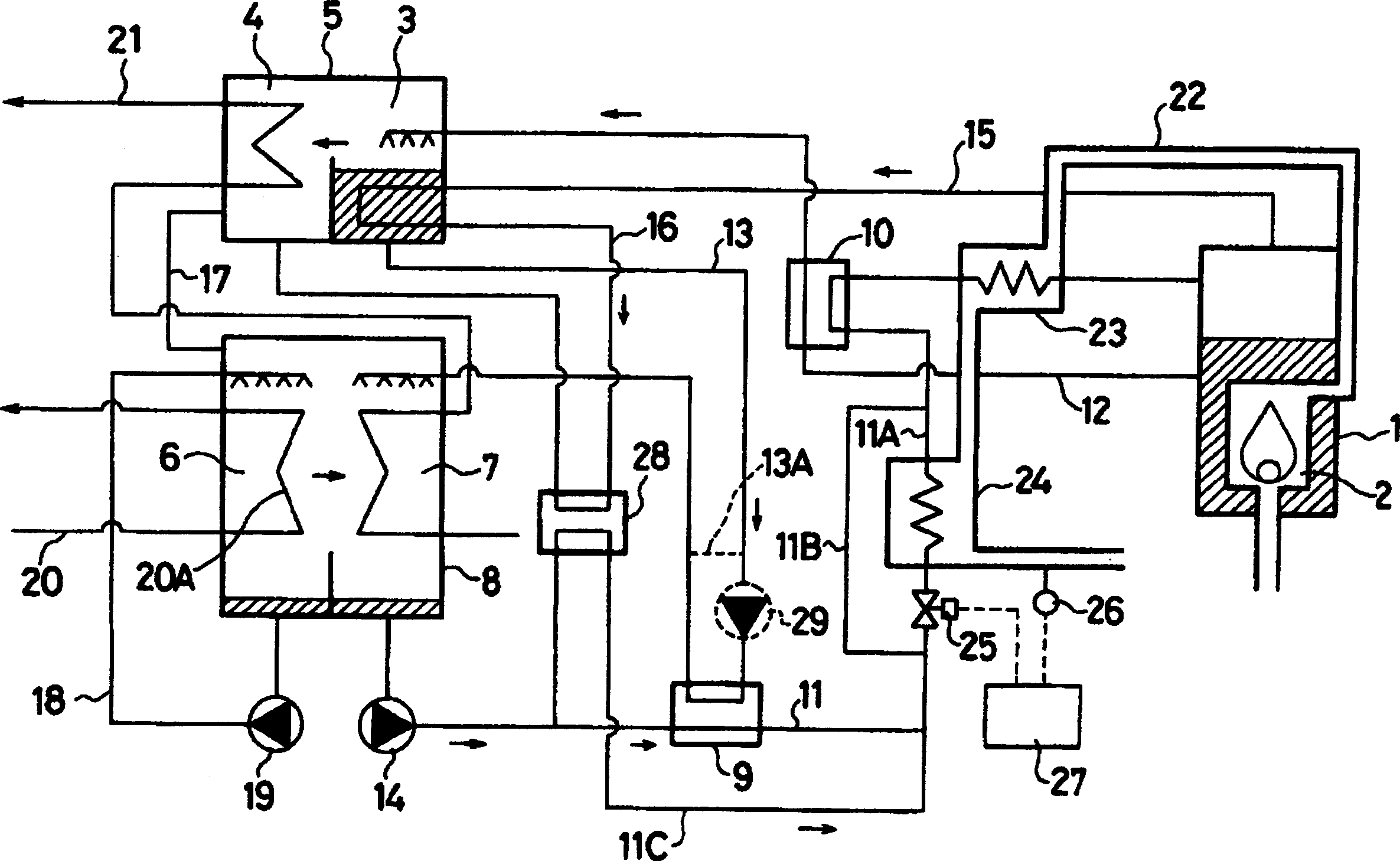

[0028] according to figure 2 , the second embodiment of the present invention will be described. In the absorption refrigerator of this second embodiment, in figure 1 A refrigerant heat recovery unit 28 is added to the piping structure of the absorption refrigerating machine of the first embodiment shown.

[0029] In the refrigerant heat recovery device 28, the refrigerant from the low-temperature regenerator 3 to the condenser 4 is heated, that is, the intermediate absorption liquid in the low-temperature regenerator 3, and the refrigerant evaporated, separated and condensed is supplied with the refrigerant from the low-temperature regenerator 3. The absorber 7 uses the absorption liquid pump 14 to transport part of the dilute absorption liquid to the high temperature regenerator 1, that is, the dilute absorption liquid flowing in the absorption liquid pipe (dilute absorption liquid branch pipe) 11C detoured in the low temperature heat exchanger 9, and Make it perform hea...

no. 3 example

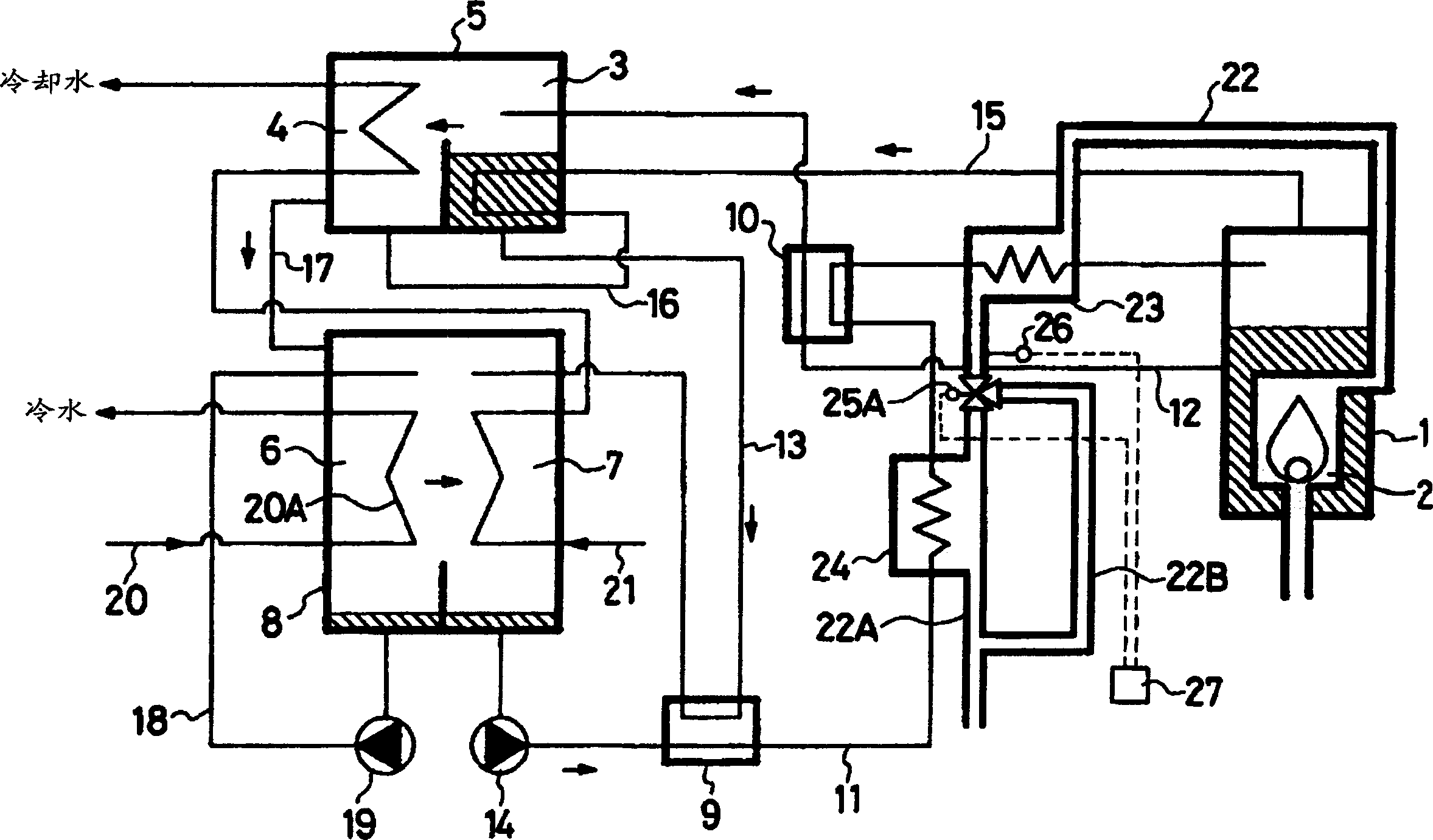

[0038] according to image 3 A third embodiment of the present invention will be described. In the absorption refrigerating machine of this example, the exhaust pipe (detour exhaust pipe) 22B detoured in the second exhaust gas heat recovery unit 24 is provided instead of the figure 1 The absorption liquid pipe (detour absorption liquid pipe) 11B equipped in the absorption refrigerator of the first embodiment shown, and the exhaust pipe 22A and the exhaust pipe (detour exhaust pipe) via the second exhaust gas heat recovery unit 24 ) 22B is provided with a switching valve 25A instead of the flow control valve 25.

[0039] The temperature sensor 26 is provided on the exhaust pipe 22 on the upstream side of the branch portion of the exhaust pipe 22A and the exhaust pipe (detour exhaust pipe) 22B. Other piping structures are the same as those of the first embodiment.

[0040] In the absorption refrigerating machine of this third embodiment, when the temperature sensor 26 detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com