Honeycomb type prick and burst resisting tire and its producing method

A honeycomb type and tire technology, which is applied to tire parts, non-pneumatic tires, transportation and packaging, etc., can solve the problems of vehicles being unable to drive, prone to tire blowouts, economic losses, etc. Effect of improving service life and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

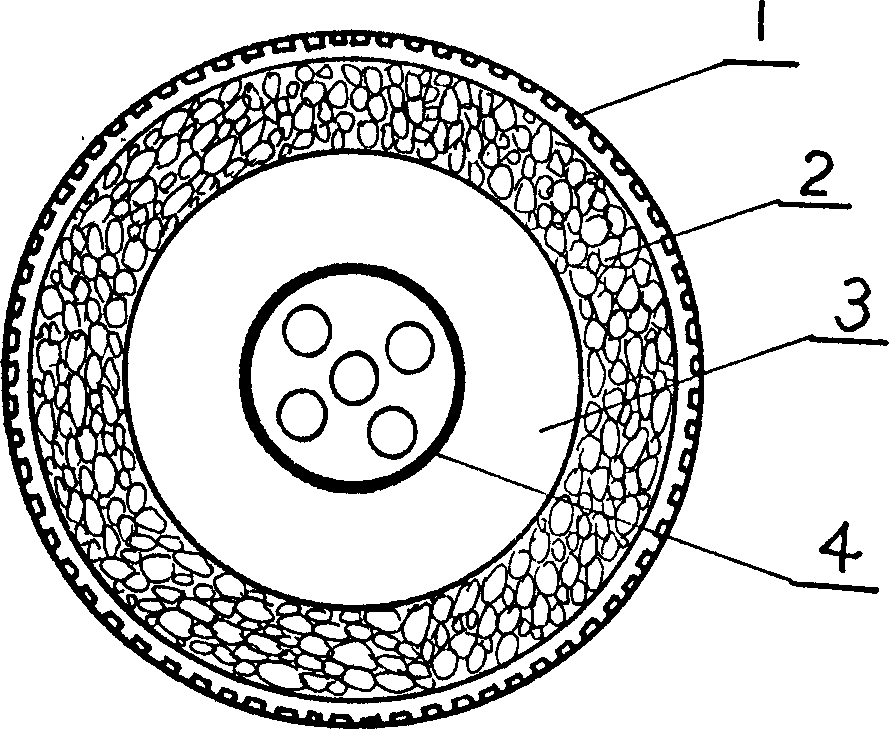

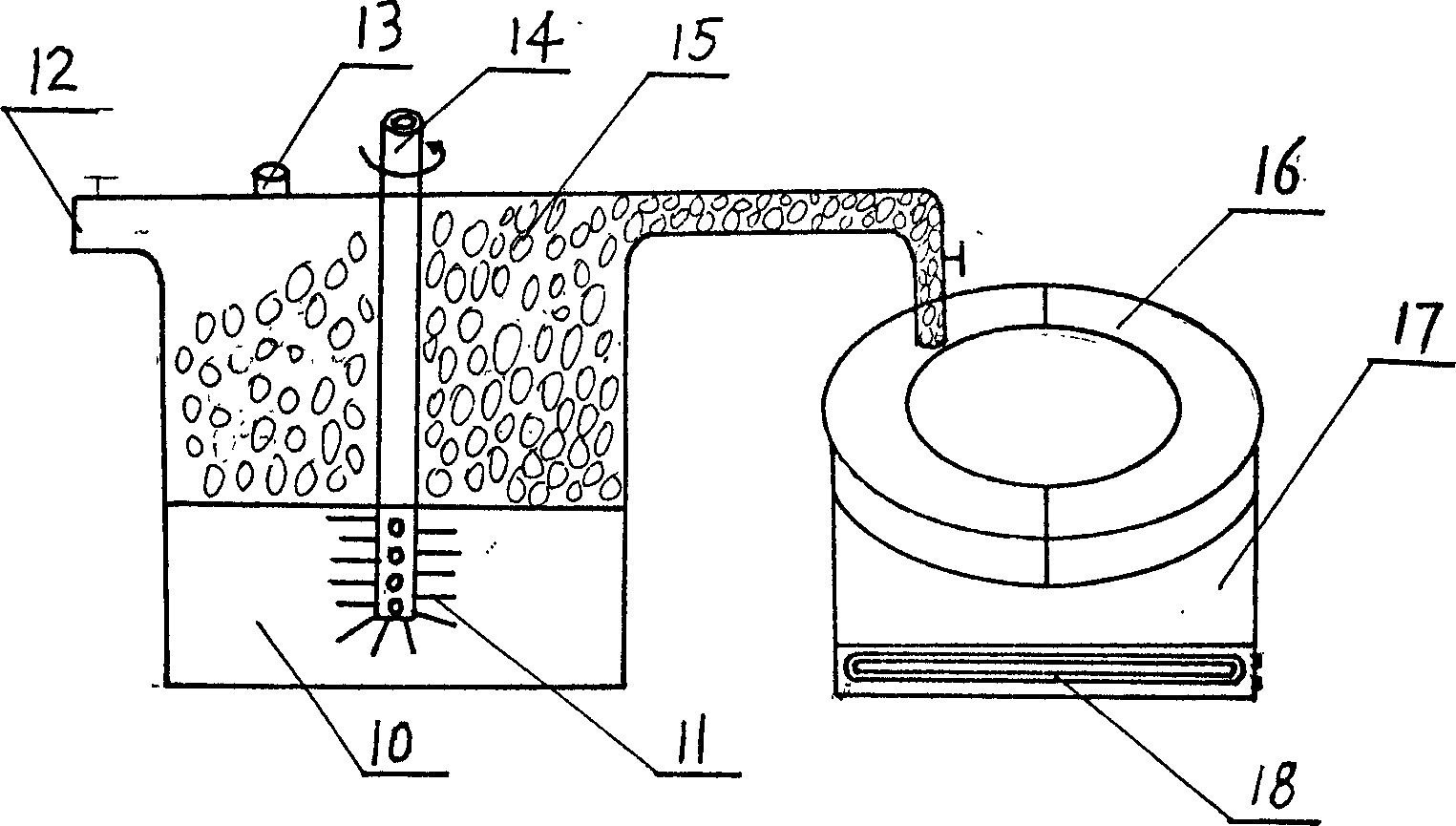

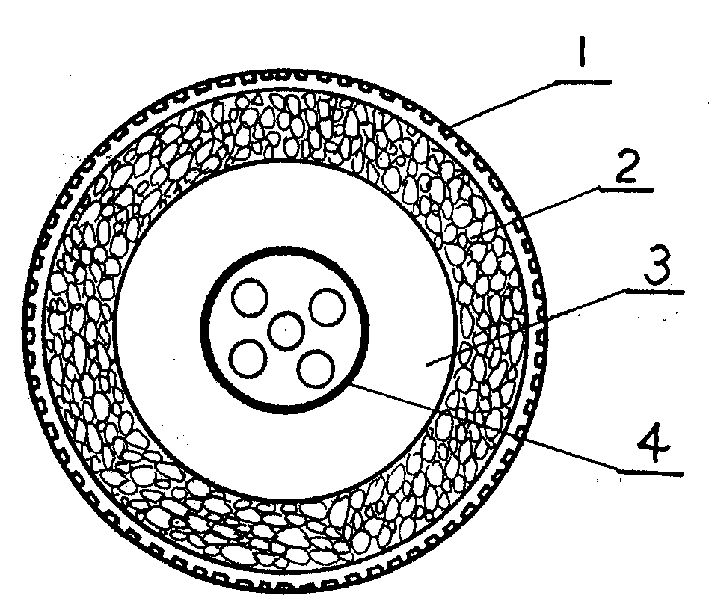

[0011] see figure 1 , the honeycomb anti-puncture and anti-explosion tire of the present invention has a cover tire 1, an inner tube 3, and a steel ring 4, and its main features are: the diameter of the inner tube 3 is smaller than the existing inner tube, and a honeycomb lining is provided between the cover tube 1 and the inner tube 3 2. The lining belt is connected with the tire 1 by adhesive, and forms a closed cavity with the pneumatic inner tube 3 to maintain the inflation pressure of the tire and achieve its use effect. In the tire of the present invention, in addition to maintaining the original tire valve, a valve is added on the steel ring 4, through which the inner tube can be checked for air leakage. If the inner tube leaks, the leaked gas will remain in the inner tube. Between the outside of 3 and the honeycomb lining strip 2, open this air valve, when there is air to spill out from air door, then show that the inner tire of a tube is broken, can carry out the repa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com