Convective motor unit of microwave oven

A technology of motor components and microwave ovens, which is applied in the field of microwave ovens, can solve problems such as noise, and achieve the effect of preventing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

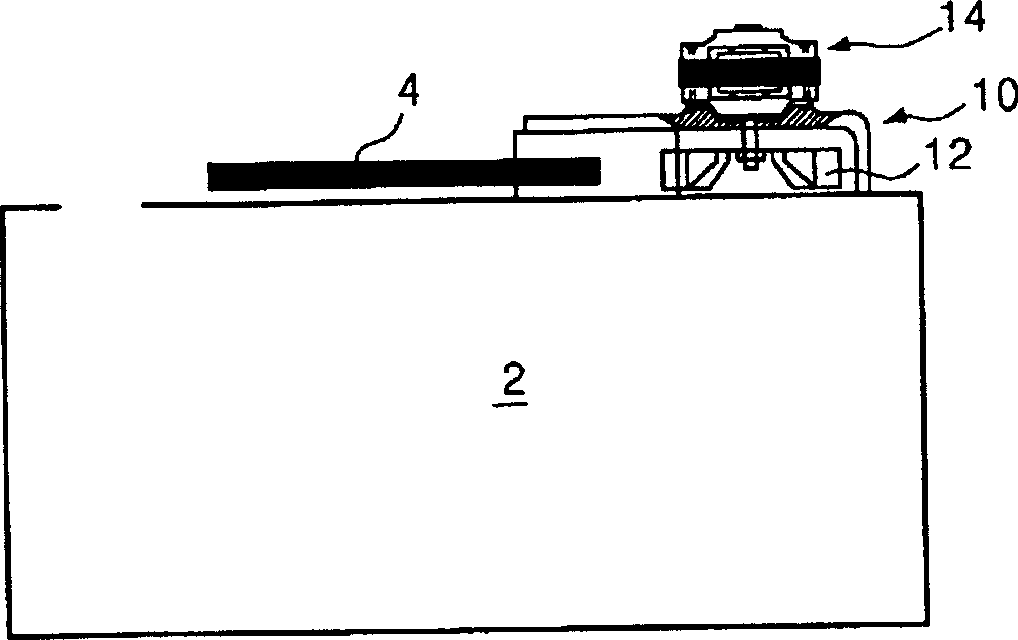

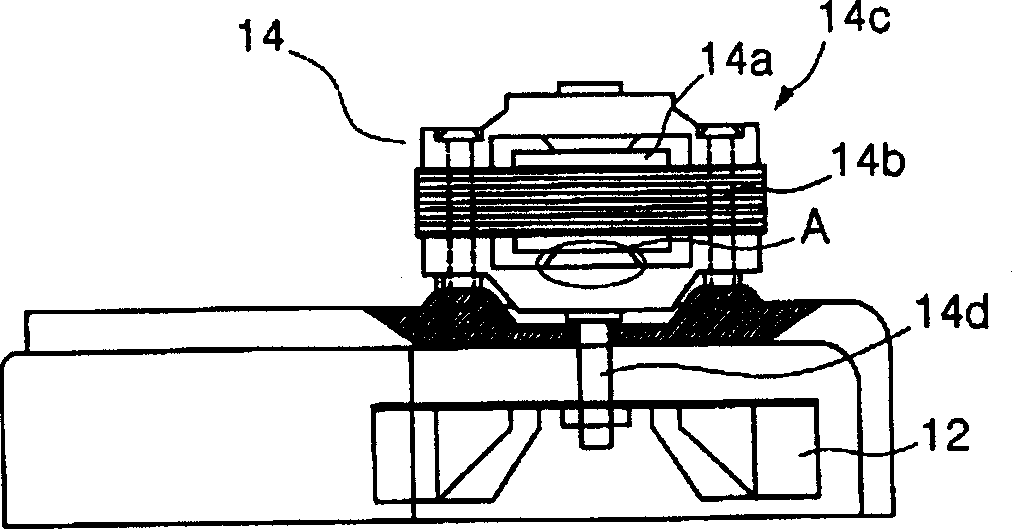

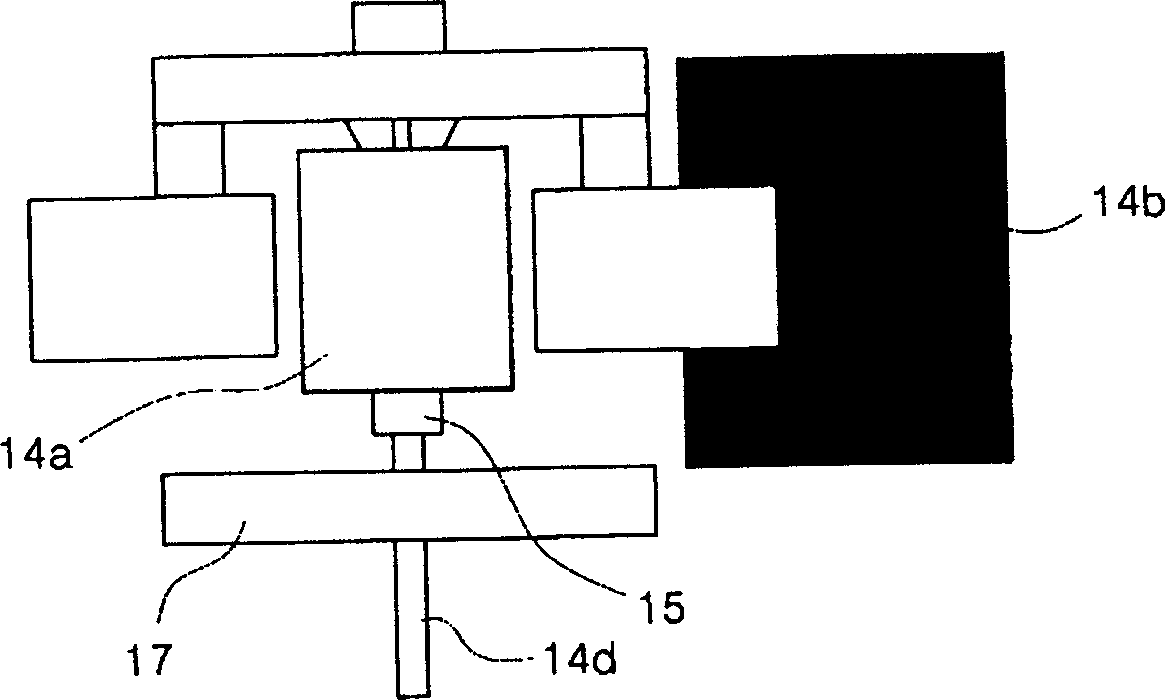

[0018] Refer to the following Figure 4 The present invention will be described in more detail.

[0019] As shown in the figure, the motor assembly of the present invention is composed of a rotating member 20 and a fixed member including a coil 30 . Since the lower end of the rotating member 20 is connected to the rotating shaft 22, the fan can be rotated. In addition, the drawing part 29 in the figure refers to the core used to concentrate the magnetic flux generated by the above-mentioned coil 30 .

[0020] The lower end of the bracket 26 has a bearing (omitted in the figure) for supporting the above-mentioned rotating shaft 22 to make it rotate smoothly, and there is a certain interval between the bracket 26 and the above-mentioned rotating member 20 .

[0021] In the present invention, the upper end of the above-mentioned rotating shaft 22 is equipped with a lubricating slice 24a and a film washer 24b. That is, the above-mentioned lubricating section 24a and film washer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com