Reciprocating motion type compressor using resonance

A reciprocating motion and compressor technology, applied in the field of compressors, can solve the problems of reduced speed, reduced amount of compressed and discharged refrigerant, and limited compressor efficiency, so as to achieve the effects of preventing loss, improving compression efficiency, and uniform speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

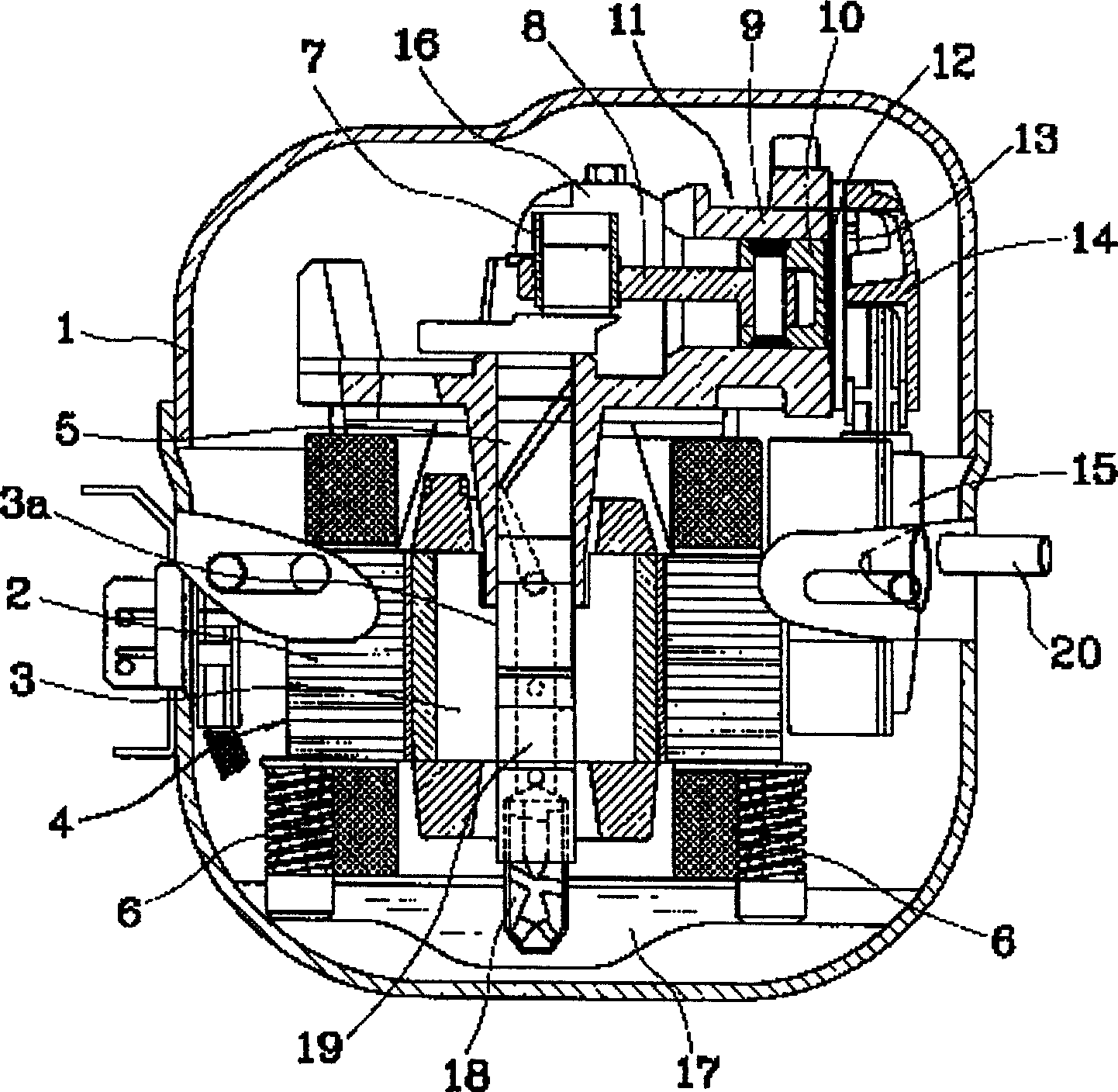

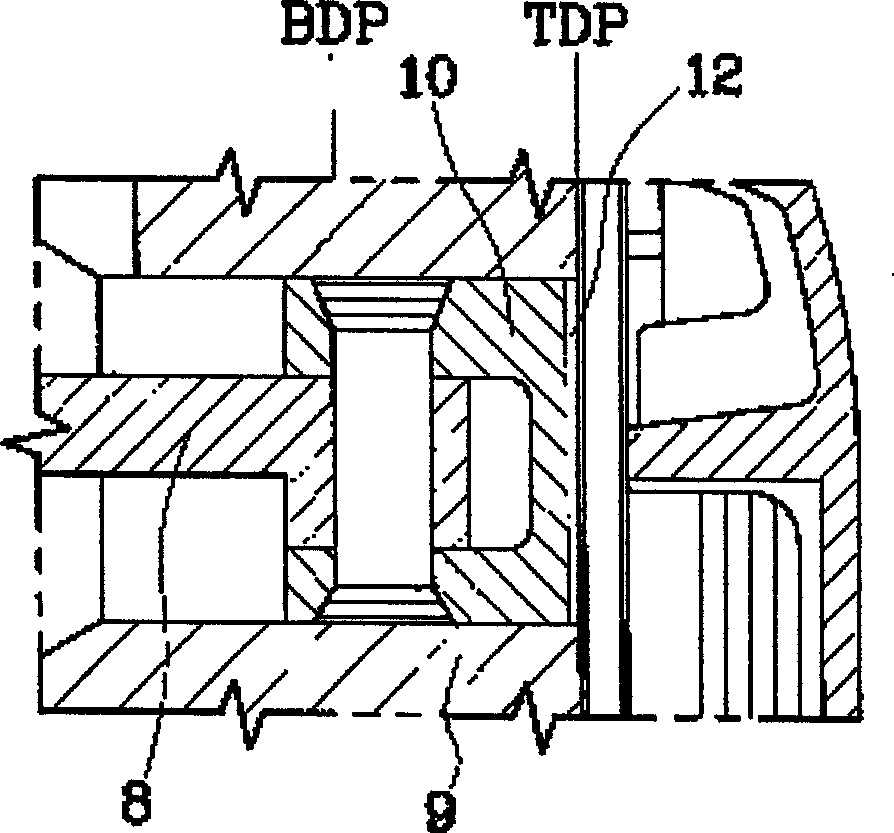

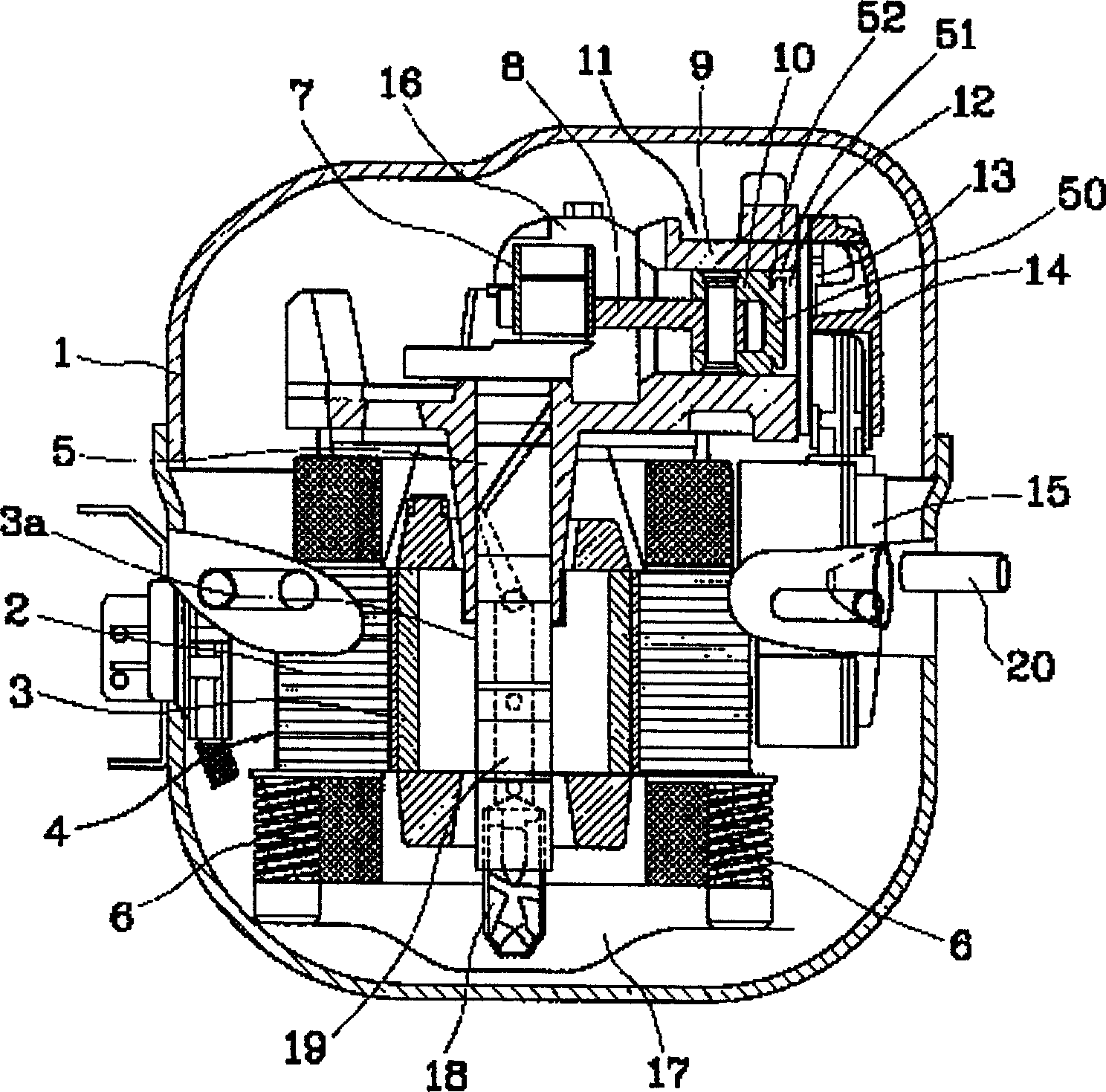

[0038] The reciprocating compressor utilizing resonance of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: image 3 It is a longitudinal sectional view of the structure of the reciprocating compressor utilizing the resonance of the present invention, Figure 4 is a partial sectional view of the installed state of the piston of the present invention, Figure 5 It is a perspective view of the structure of the piston of the present invention. As shown in the figure, the basic structure is the same as that of the conventional compressor, and the same parts are described with the same symbols.

[0039] A rotating part 4 composed of a stator 2 and a rotor 3 is installed in a closed container 1 having a closed space. The shaft of the rotor 3 is pressed into the hole 3a to press the rotating shaft 5, and the upper end of the rotating shaft 5 is inserted into the shaft supporting hole 6a. . In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com