Tube preform and method for producing glass containers from a tube preform

A glass container and semi-finished product technology, applied in glass forming, glass remolding, manufacturing tools, etc., can solve the problems of waste of semi-finished pipes and increase in the cost of semi-finished pipes, so as to improve production capacity, control pressure conditions, and reliable pressure conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

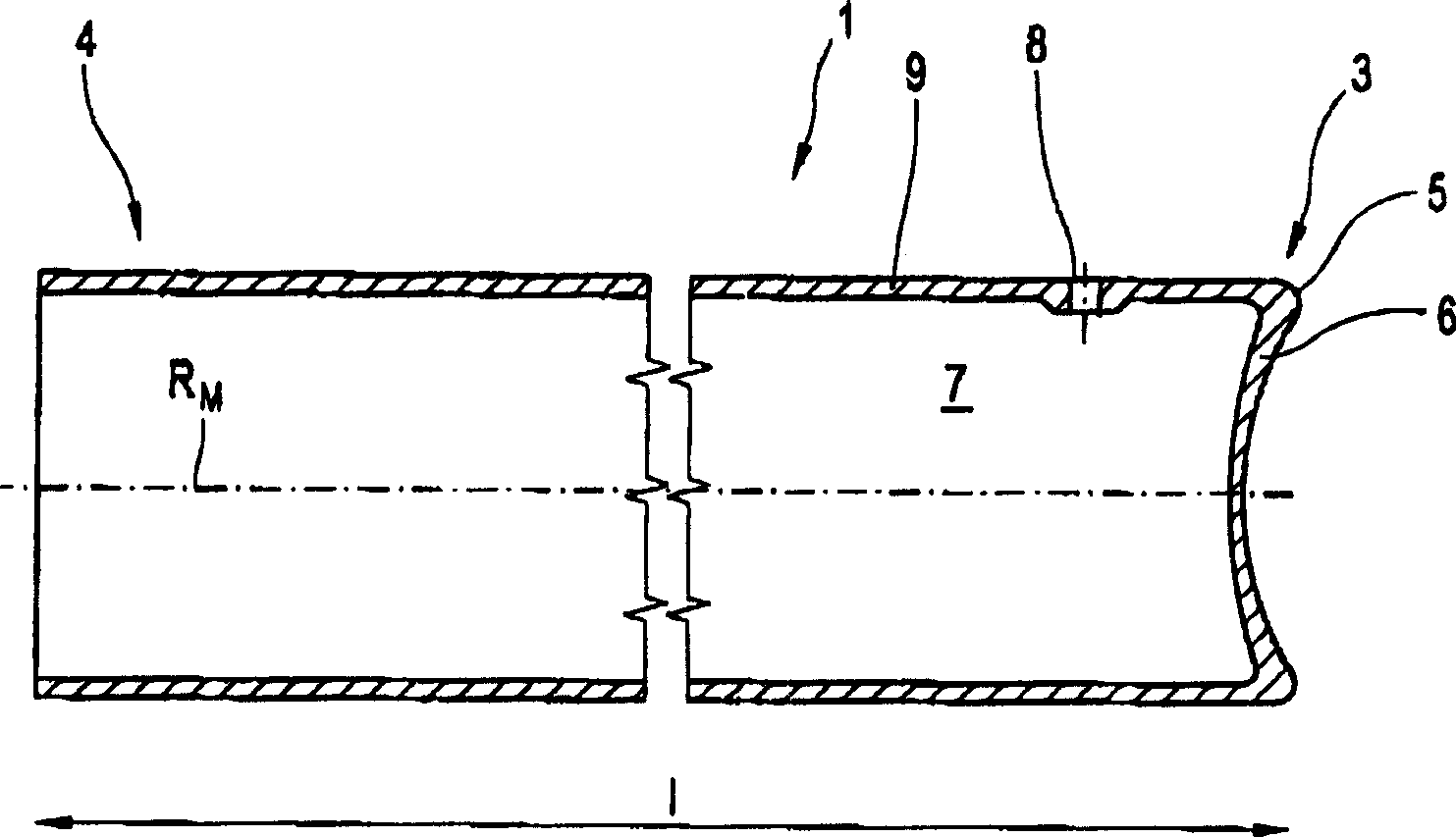

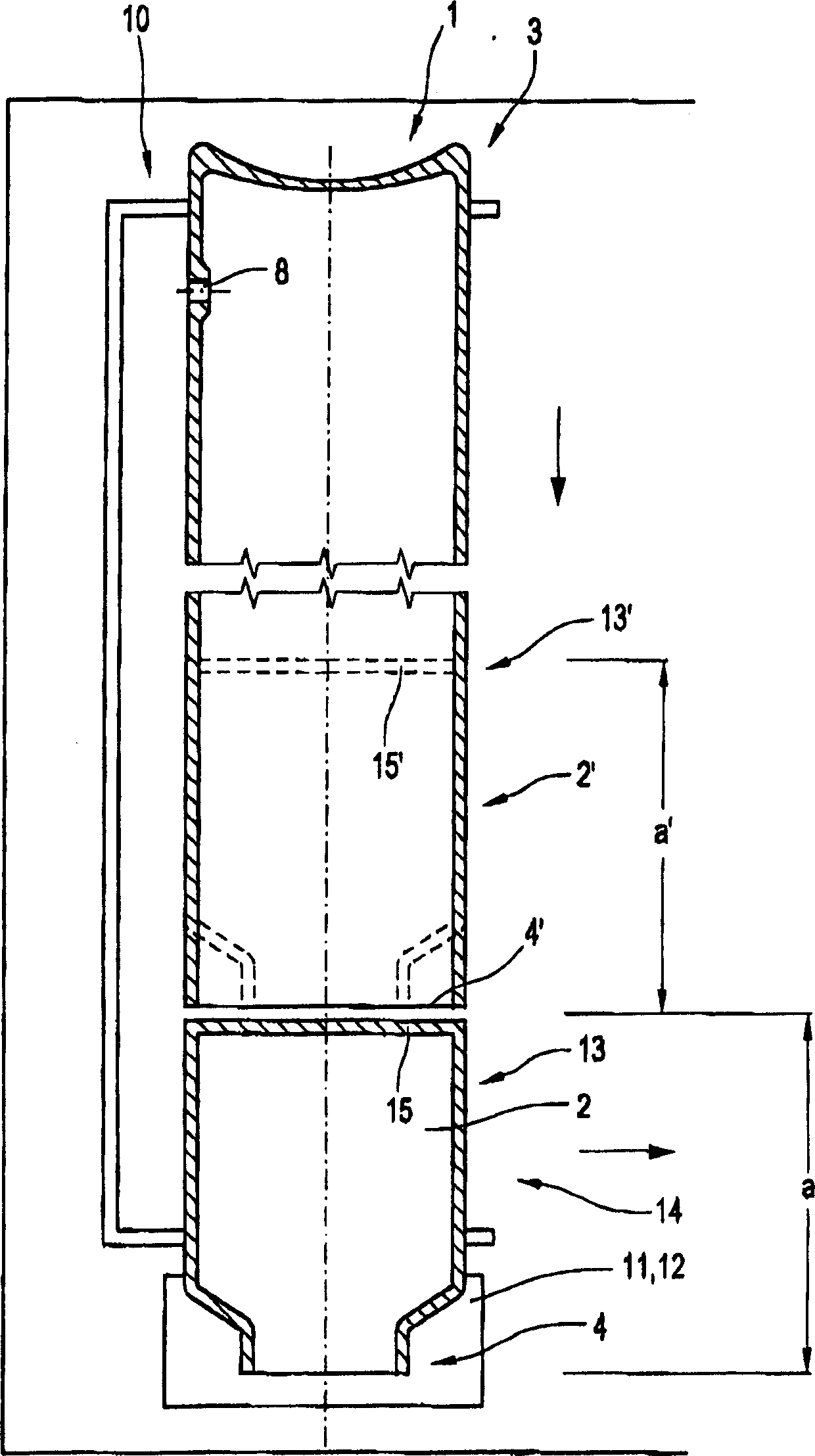

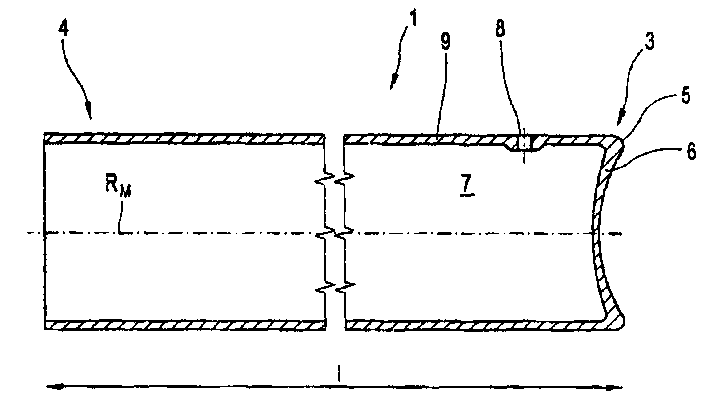

[0031] figure 1 A schematic diagram of a longitudinal section of a semi-finished tube 1 according to the invention is shown for the production of glass containers 2, such as glass vials, glass ampoules or glass syringes, and is especially suitable for pharmaceutical use. Shown is a longitudinal section through a semi-finished pipe 1 . It has two end regions, namely a first end region 3 and a second end region 4 . Here the first end region 3 is closed. For this purpose, a base 6 is provided directly on the pipe end 5 . The base can now protrude, as shown, into the semi-finished tube interior 7 delimited by the walls of the base. It is also conceivable that the bottom 6 is flat (not shown here). Furthermore, according to the invention, the semi-finished tube 1 is open in the second end region 4 . Furthermore, the semi-finished tube 1 has a vent hole 8 which is machined into the wall 9 of the semi-finished tube 1 and is preferably located in the vicinity of the bottom 6 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com