Flexible flare line system based on expansion joint compensation

A flexible system and torch pipeline technology, applied in expansion compensation devices, pipe components, pipes/pipe joints/pipe fittings for pipelines, etc., can solve the problems of low pipeline flexibility and reliability, high pipeline stress, and waste of raw materials, etc. Achieve the effect of improving pipeline safety and reliability, reducing pipeline stress and pipeline support load, and reducing pipeline diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

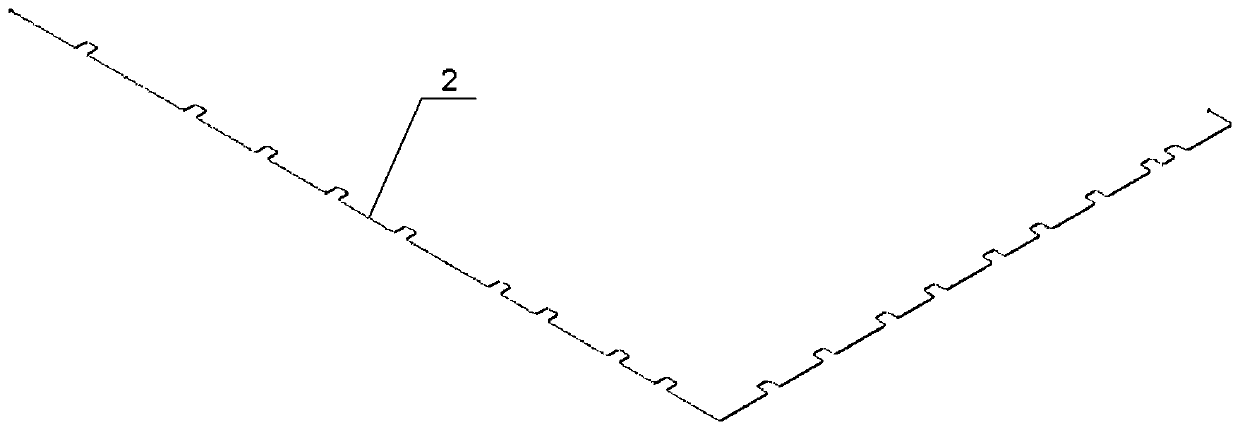

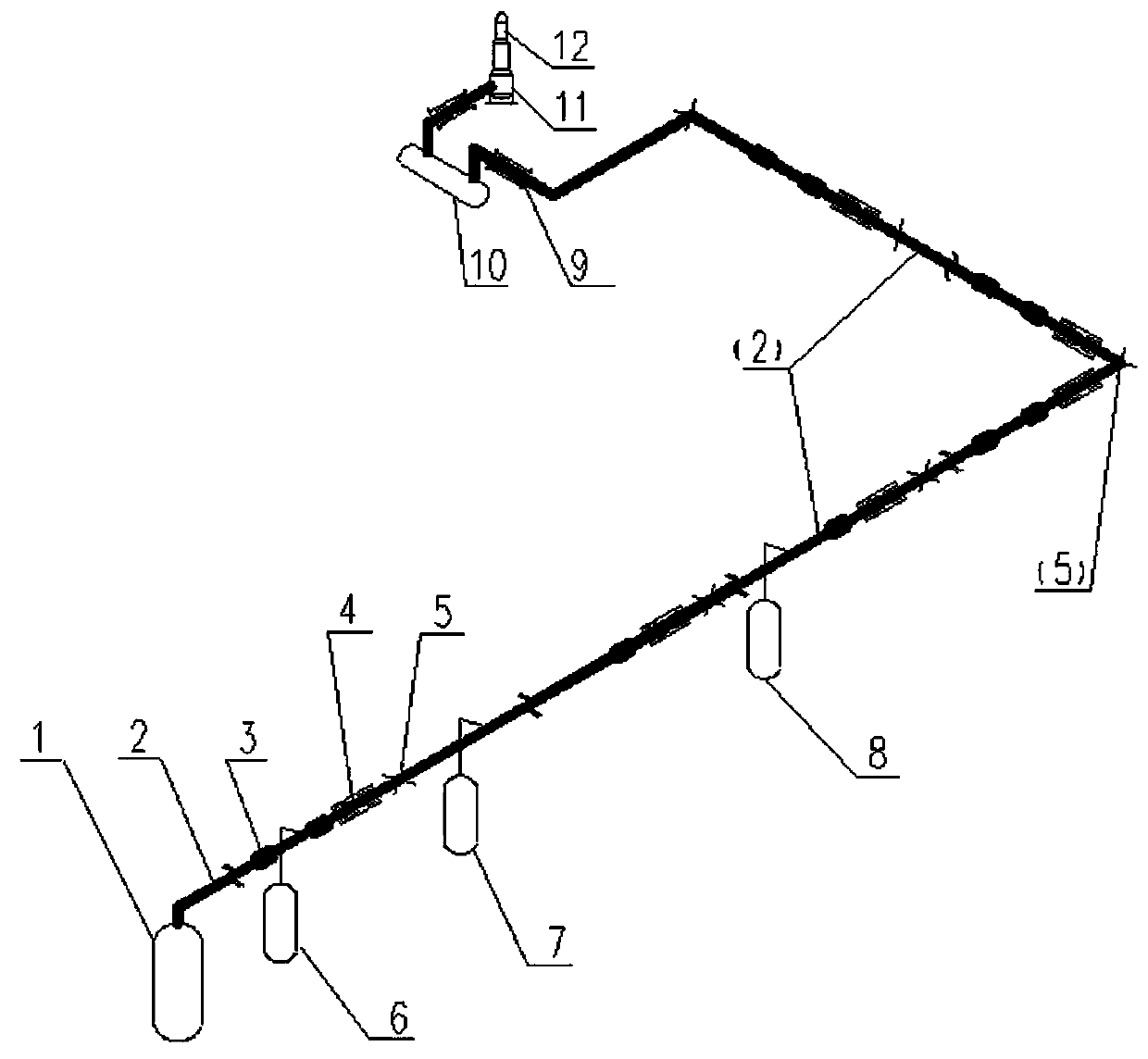

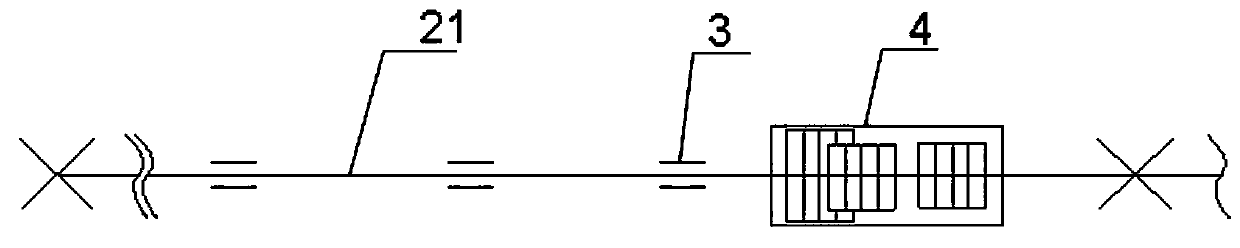

[0024] Such as figure 2 As shown, a flare pipeline flexible system based on expansion joint compensation includes an overhead torch main pipe 2, a reaction device and a liquid separation tank 10, the reaction device and liquid separation tank 10 are connected to the flare main pipe 2, and the reaction device can be There are multiple sets. The medium discharged from the reaction device enters the torch main pipe 2, and enters the liquid separation tank 10 through the torch main pipe 2. The torch main pipe 2 is composed of a straight pipe section 21 and a curved pipe section 22. The system also includes an explosion-proof straight-through external pressure straight pipe pressure balance The expansion joint 4 and the compound expansion joint 9 of the universal hinge pull rod, the thermal displacement of the straight pipe section 21 is compensated by the explosion-proof straight-through external pressure straight pipe pressure balance expansion joint 4, and the thermal displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com