Fastening element

A technology of fasteners and components, applied in the field of fasteners, can solve the problems of not being able to obtain permanent and reliable fixation, and achieve the effect of simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

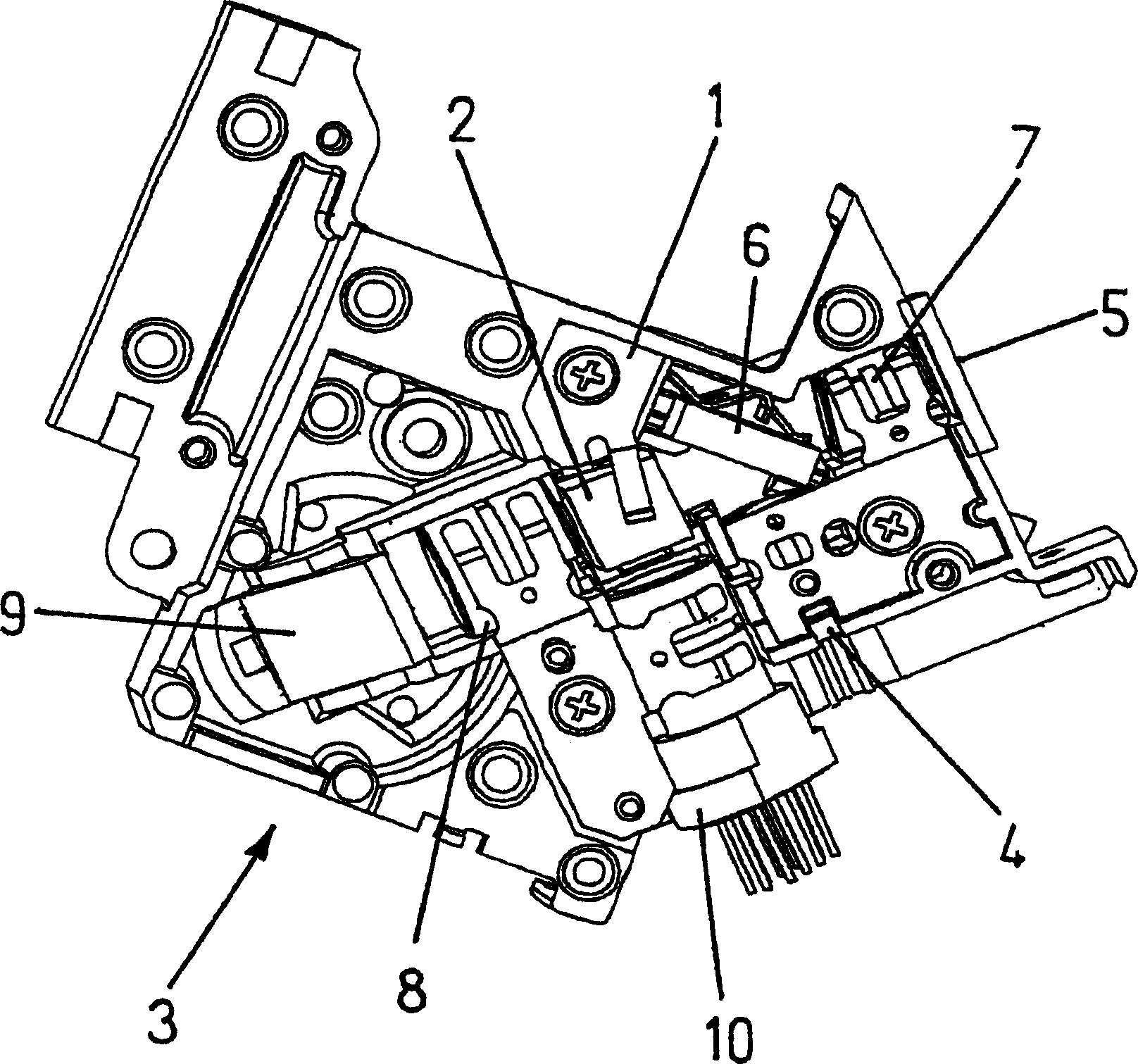

[0017] figure 1 Shown is the use of a fastener 1 according to the invention for adjusting an optical component, namely a beam splitter, in the optical path of a pickup 3 in a unit for recording information on an optical Information is reproduced on or from a recording medium.

[0018] The pickup 3 shown here is a DVD pickup, which can operate in both DVD mode and CD mode. In DVD mode, use is made by means of laser diode 4 and detector 5 . The laser beam emitted by the laser diode 4 is reflected on the half mirror 6 and passes through the beam splitter 2 . The latter is also used to reflect the return beam from the disc and deflect it to the detector 5 . In this case, the light beam passes through the half mirror 6 and is focused with the help of the lens 7 . Reference numeral 8 denotes a collimator, and 9 denotes a mirror also arranged in the optical path of the pick-up 3 . In CD mode, this use takes place by means of the holographic element 10 .

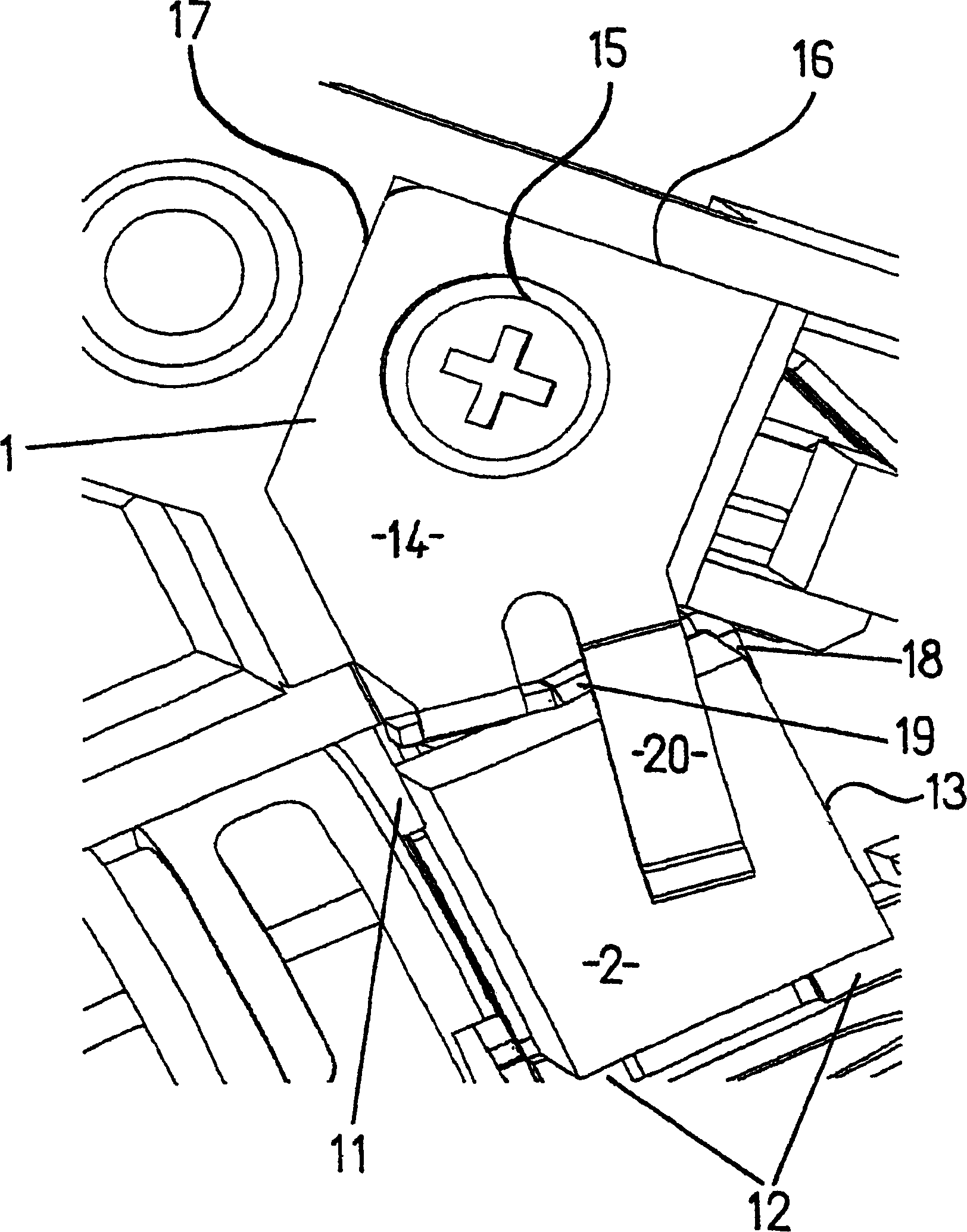

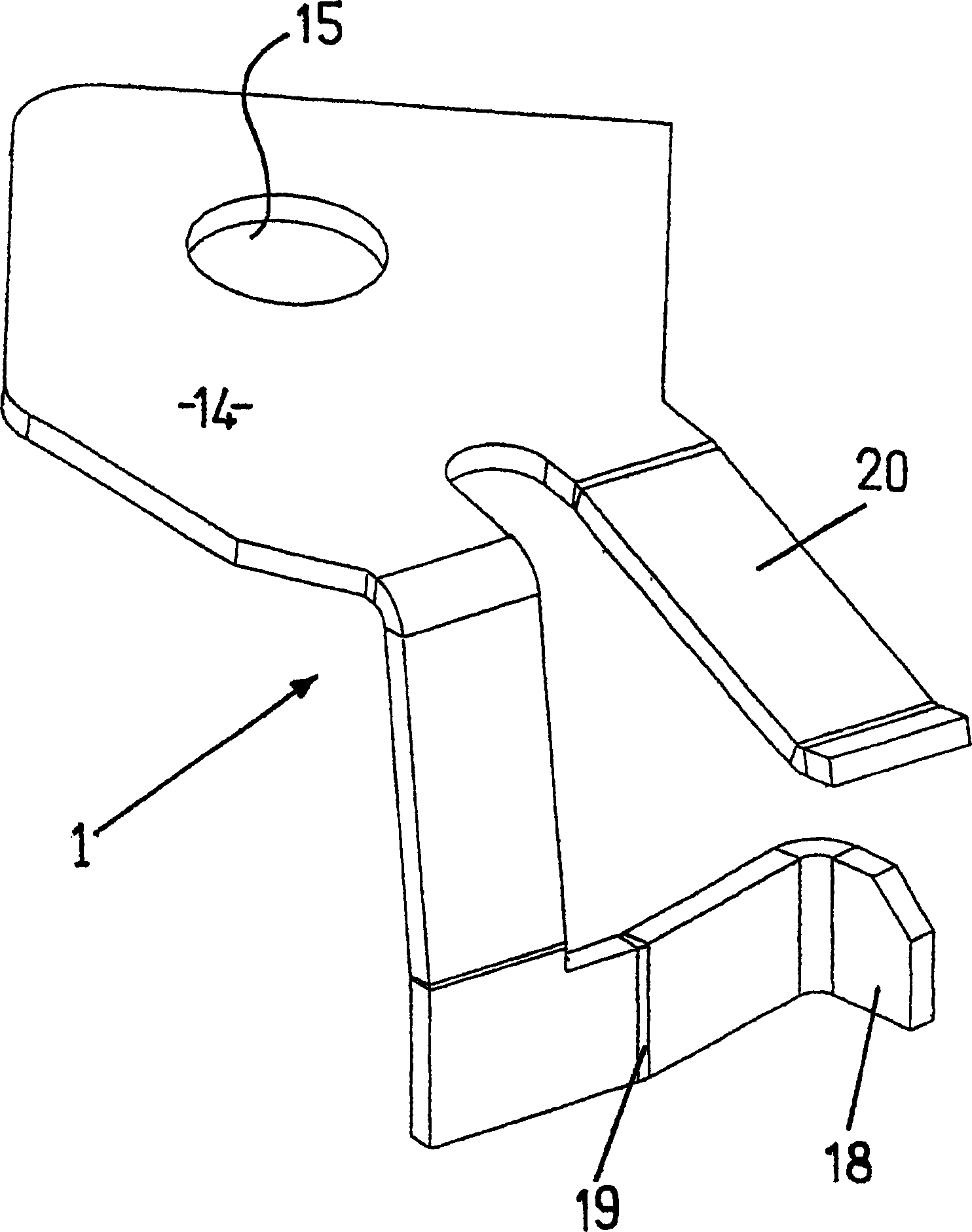

[0019] figure 2 Show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com