Bearing projection measuring devices

A technology for measuring devices and protrusions, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems such as measurement value errors, achieve the effects of improving measurement accuracy and eliminating measurement system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

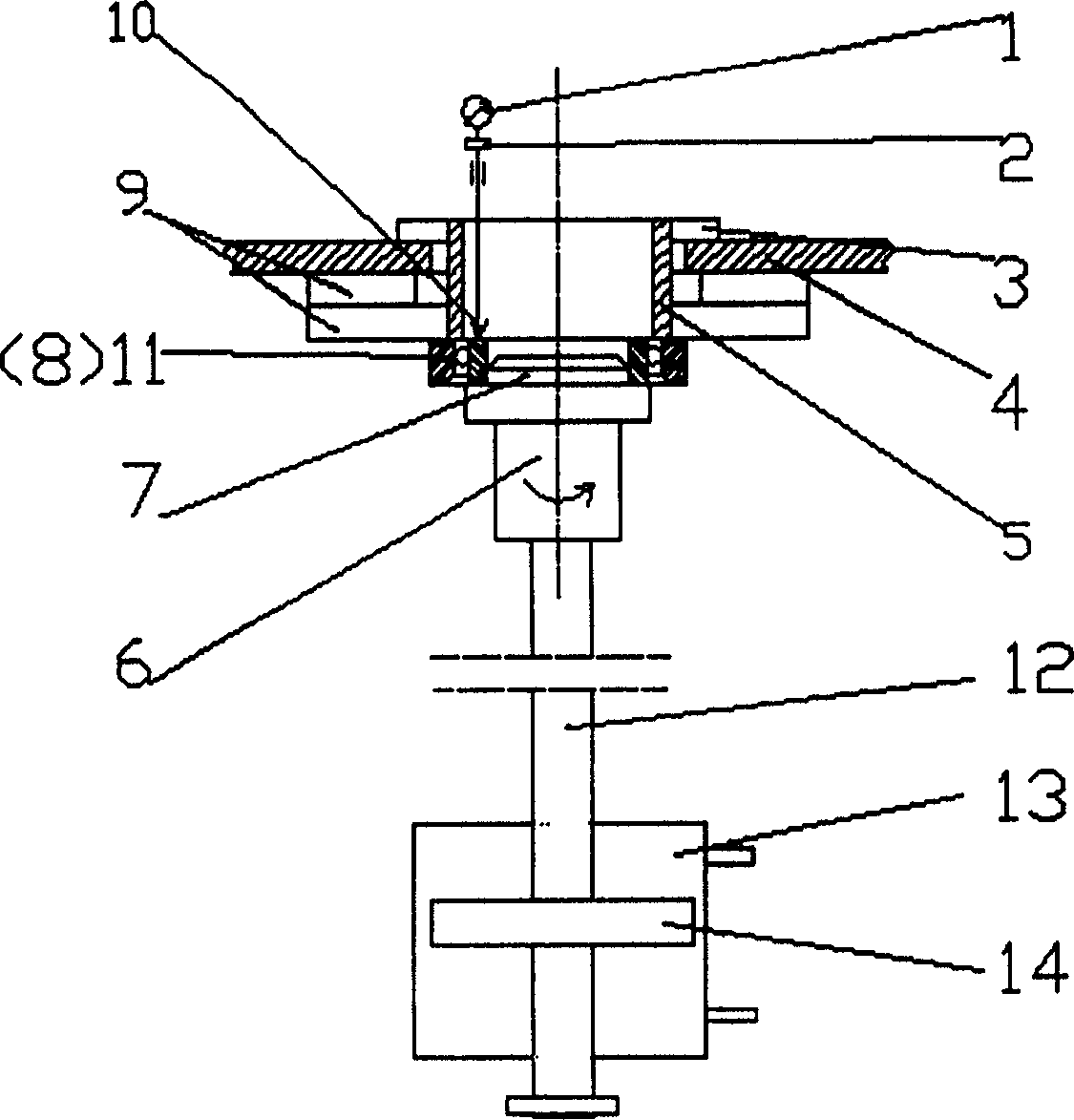

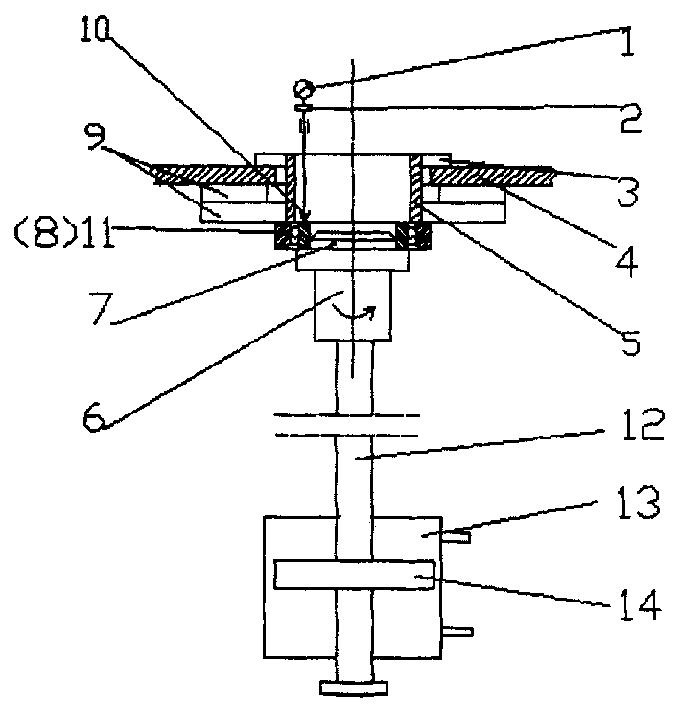

[0014] As shown in the accompanying drawings, the present invention consists of mechanical parts, pneumatic control parts and electrical parts. The mechanical part includes the central shaft 12 whose lower end is connected to the piston 14 installed in the cylinder 13, the upper end of the central shaft 12 is equipped with an air main shaft 6, and the upper end of the air main shaft 6 is equipped with a mandrel 7 that can match the standard ring 8 or the bearing 11 to be tested There is a central hole on the workbench 4, the lower end surface of the workbench 4 is coaxially connected with the upper ring of the air-floating thrust bearing 9, and the lower ring of the air-floating thrust bearing 9 is connected with the connecting ring 5 sleeved in the center hole of the workbench 4 The lower end is fixed, and the upper end of the connecting ring 5 is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com