Heavy gas turbine

A gas turbine, heavy-duty technology, applied in the field of power machinery, can solve the problem that the performance is not always satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

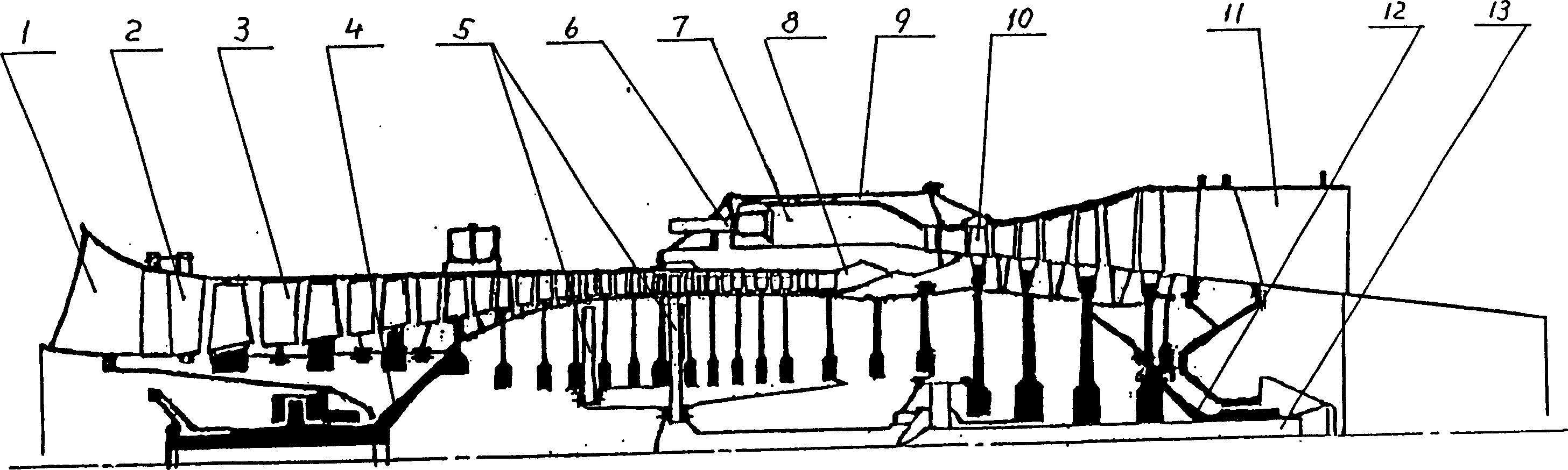

[0030] Overall structure of the present invention is as figure 1 As shown, the recirculation ring tube combustion chamber composed of intake casing 1, imported adjustable guide vane 2, multi-stage axial flow compressor 3, diffuser 8, and multi-stage flame tube 9, multi-stage axial flow ventilation Main components such as flat 10 and exhaust casing 11 constitute. The inner and outer casings of the intake casing 1 are integrally cast with 19 force-bearing rectifying support plates, and the casings of each component are connected by axial bolts. The compressor 3 and the turbine 10 are both disc-drum structures. In the meantime, they are tightly connected by axial bolts and form a drum-type compressor-turbine rotor, which is supported on two sliding flat bearings at the front and rear, showing a double-support and single-rotor structure.

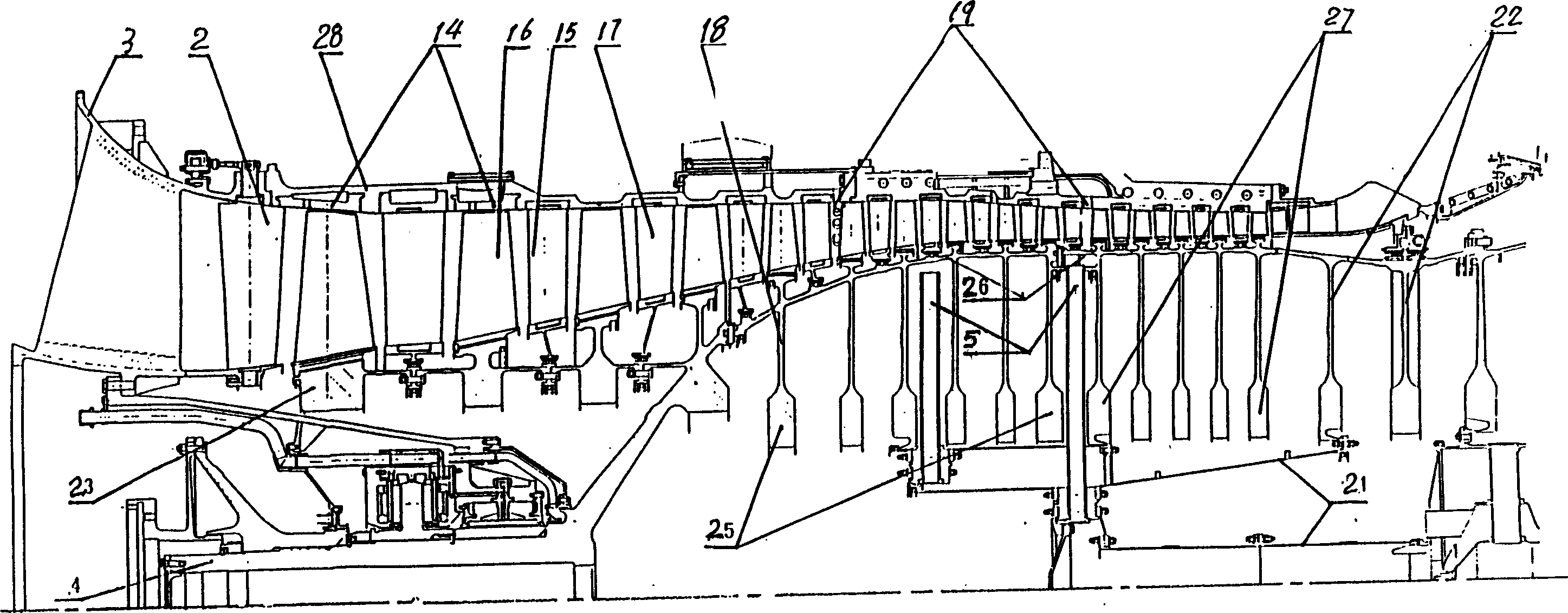

[0031] Air compressor 3 of the present invention is as figure 2 shown.

[0032] It consists of a compressor stator (28) and a compressor ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com