Driving circuit for power semiconductor element

A technology of power semiconductors and drive circuits, which is applied in the manufacture of semiconductor devices, electrical components, semiconductor/solid-state devices, etc. It can solve the problems of short-circuit detection lag and failure to protect IGBT1, and achieve the effects of improving reliability and preventing malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] One embodiment of the present invention will be described below.

[0057] Embodiment 1

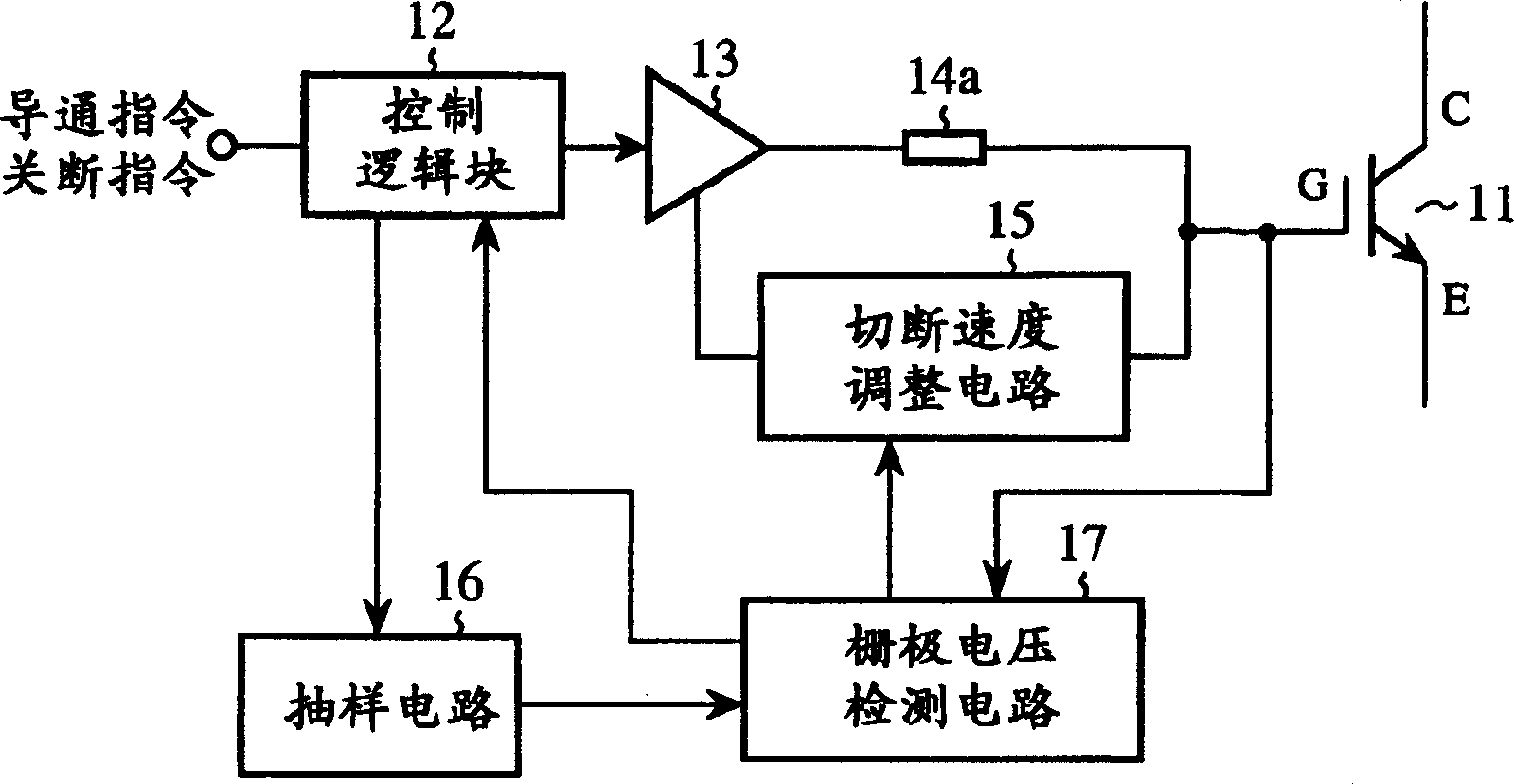

[0058] figure 1 It is a configuration diagram showing the drive circuit of the power semiconductor element according to Embodiment 1 of the present invention, and in the figure, 11 is an IGBT (insulated gate bipolar transistor) as the power semiconductor element. Here, the power semiconductor element is not limited to IGBT, and may be a voltage-driven semiconductor element such as MOSFET, for example.

[0059] 12 is a gate command to turn on the IGBT11 is output to the buffer 13 if an on command is input from the outside, and a gate command to turn off the IGBT11 is output to the buffer 13 if an off command is input from the outside. The control logic block, 13 is a buffer for driving the IGBT11 according to the gate command output from the control logic block 12, 14a is a turn-on gate resistance, and 15 is the IGBT11 that is turned off according to the detection of an abnormalit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com