V concave profile semi-float slide added motorboat

A technology for skid boards and motor boats, which can be applied to ships, special-purpose ships, motor vehicles, etc., and can solve the problems of slow speed, large sailing resistance, and poor steering performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

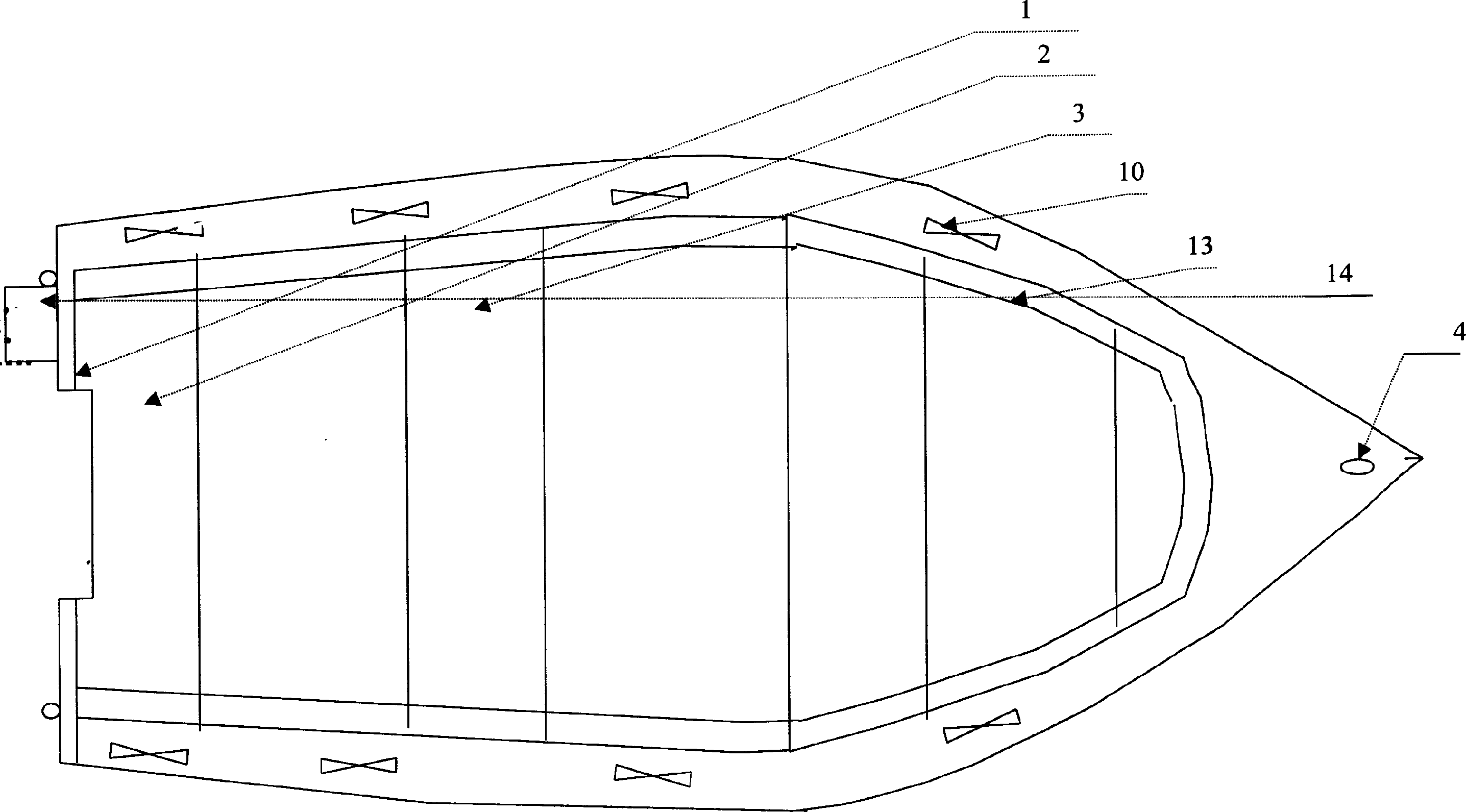

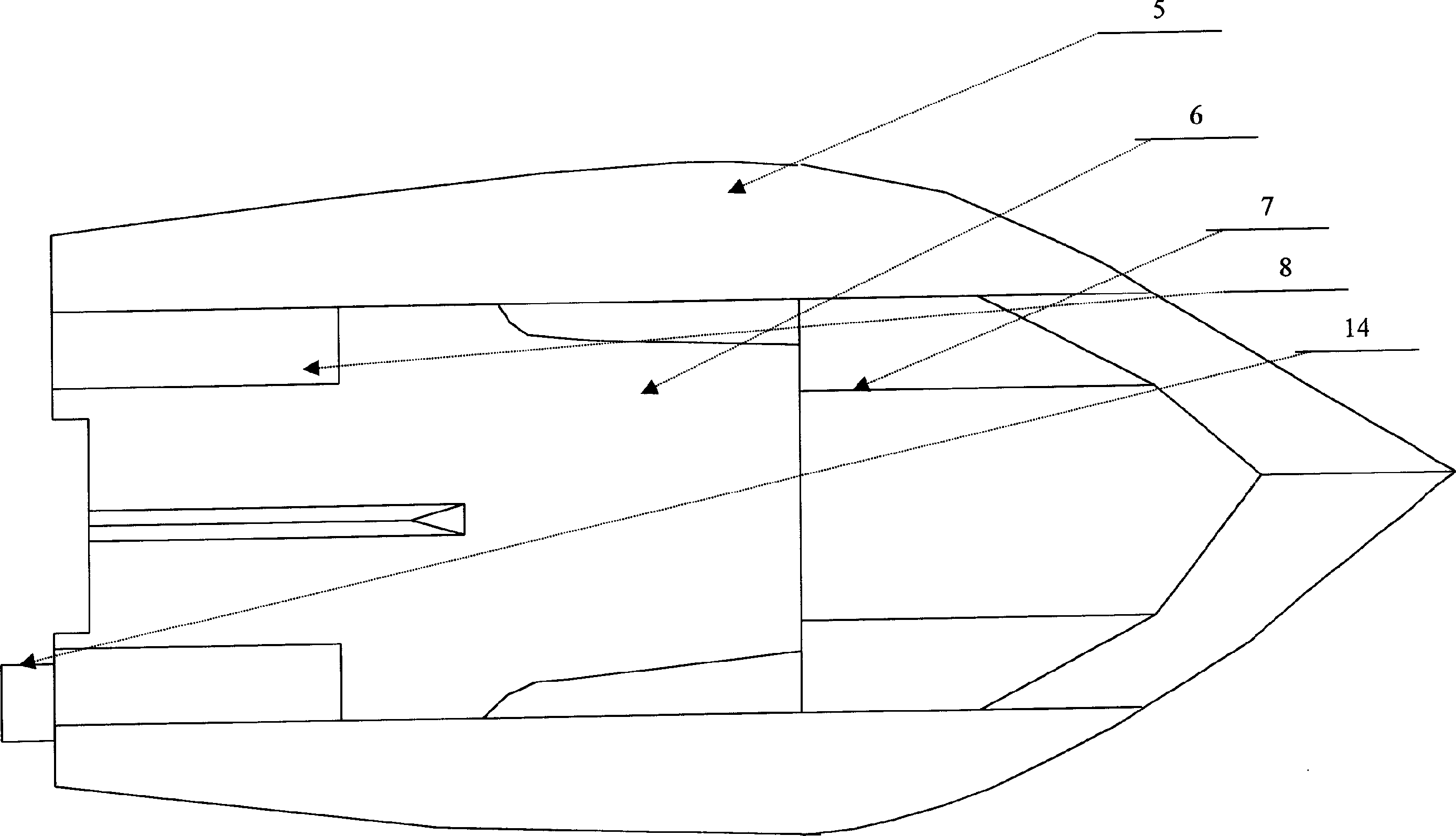

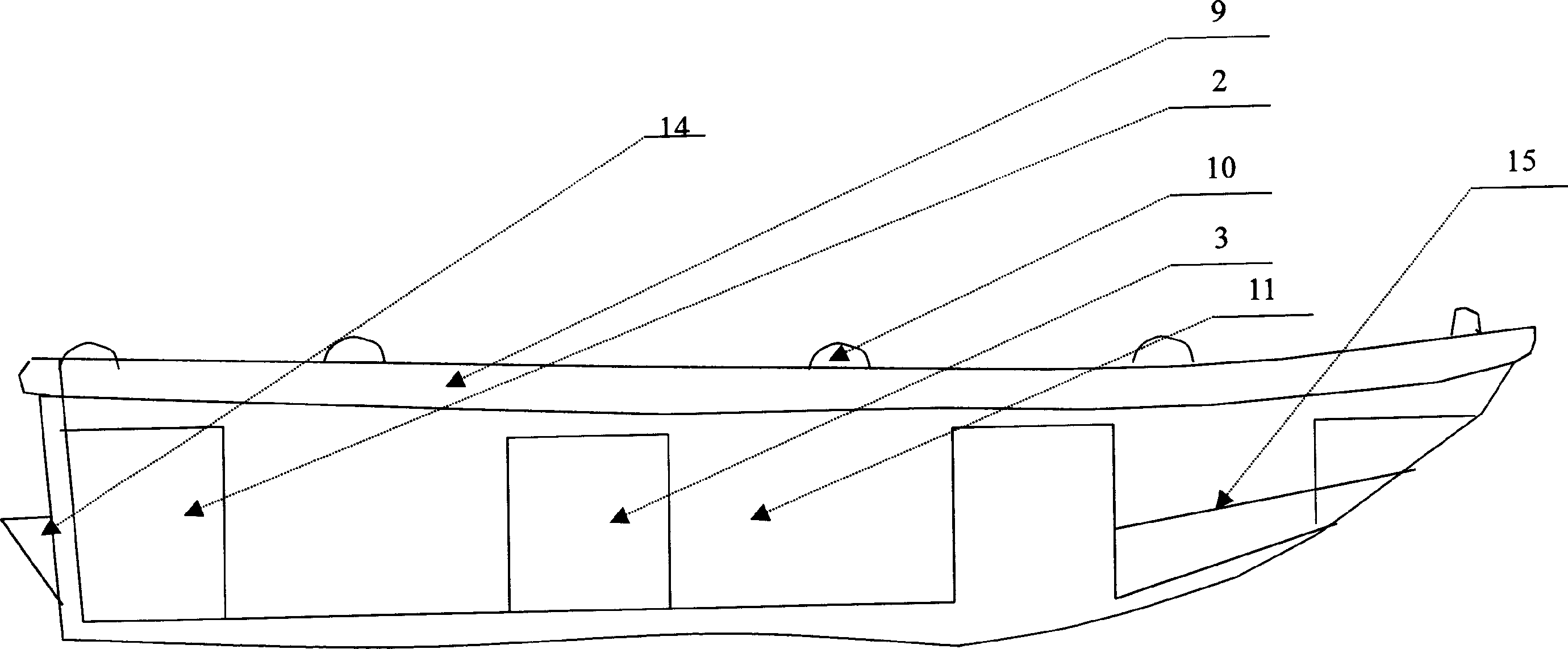

[0021] A V-concave fault semi-floating body plus a sliding board type motor boat (boat, boat), which is composed of a boat (boat, boat) body, a sliding part, a control device, a power part, and a propulsion part. The hull is made up of side boards (5), main planing surfaces (6) at the bottom of boats (ships, boats), and stern hanger plates (1) of boats (ships, boats). The sliding part is composed of inner floating body (7) and wave pressing plate (8), forming a fault shape. The boat (ship, boat) is designed to be drop-shaped from the bow to the stern, which conforms to hydrodynamics, so that the boat (boat, boat) During driving, the sailing resistance is reduced, the wave resistance is increased, and the boat (ship, boat) can bear a large load.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com