Interpolymer paste resin and its preparing method

A technology of paste resin and copolymerization, which is applied in the field of preparing vinyl chloride-vinyl acetate copolymer paste resin, and can solve problems such as inability to form paste, irregular shape, and inability to apply PVC paste resin processing and application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Feeding formula: vinyl chloride 95 (weight percent, the same below), vinyl acetate 5, pure water 120, sodium lauryl sulfate 1.2, C 12-26 Fatty alcohol 1.5, azobisisoheptanonitrile 0.02, toluene 0.1, ethylhexyl peroxydicarbonate 0.01.

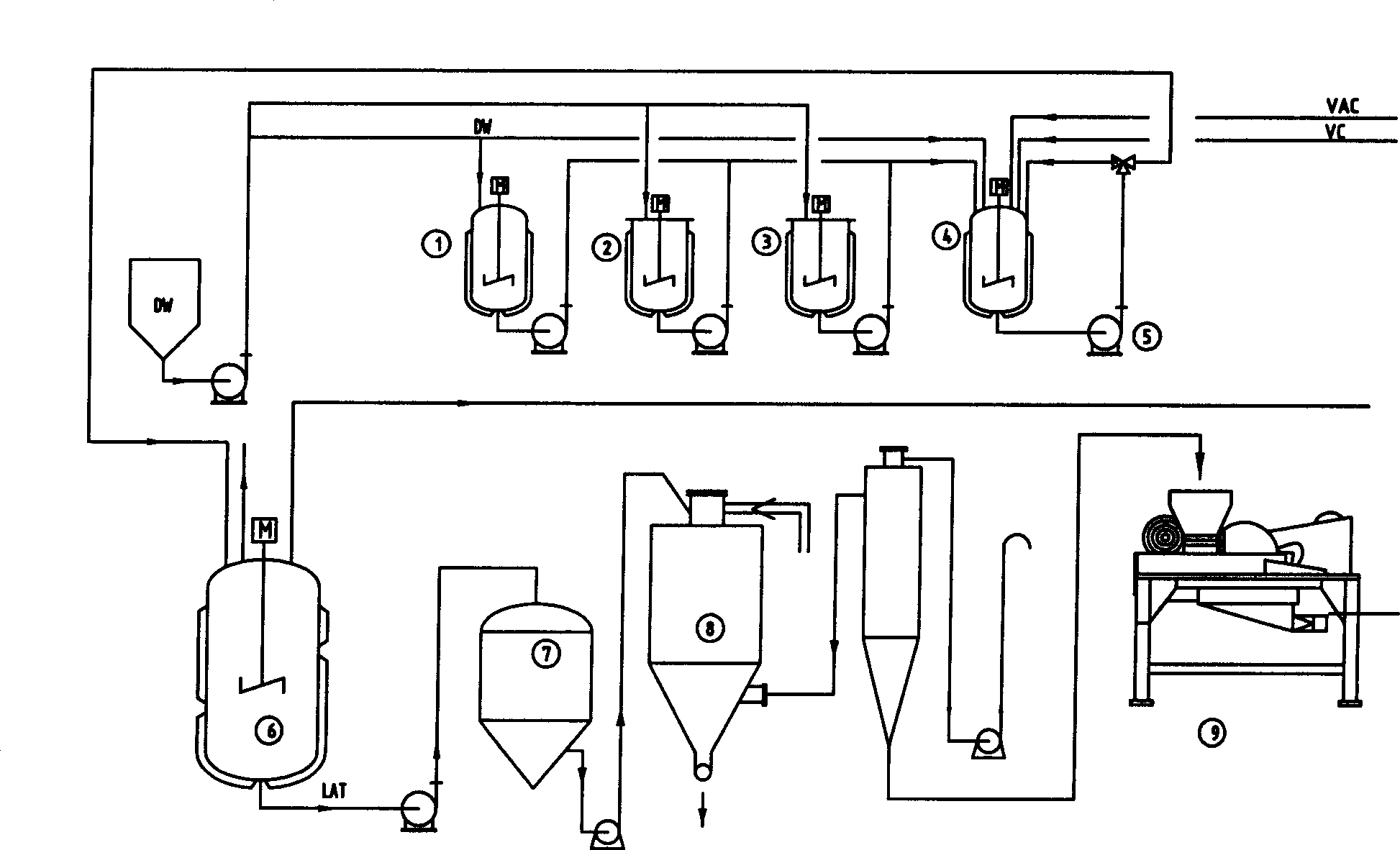

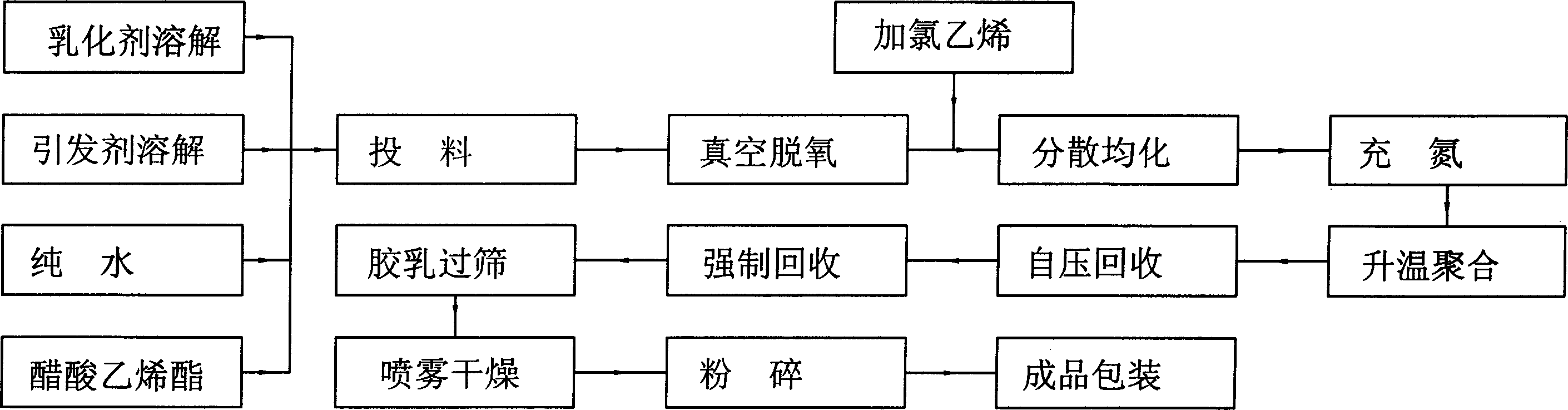

[0028] Sodium lauryl sulfate, C 12-26 Fatty alcohol, 10 parts of pure water (DW) was added to the emulsifier dissolving tank ( figure 1 Stir in equipment 3). Azobisisoheptanonitrile, toluene, 5 parts of pure water are added to initiator dissolving tank 1 ( figure 1 Stir in equipment 1). Add ethylhexyl peroxydicarbonate, 5 parts of pure water to initiator dissolving tank 2 ( figure 1 Stir in equipment 2). Simultaneously vinyl chloride (VC), vinyl acetate (VAC), pure water (100 parts), emulsifier after dissolving, initiator are added dispersion tank ( figure 1 Middle equipment 4), open dispersion pump ( figure 1 Middle equipment 5), while dispersing, towards the polymerization kettle ( figure 1 Middle equipment 6) feeding, the dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com