Recording apparatus

A technology of recording device and pushing device, applied in the direction of printing device, transportation and packaging, rigid support of bearing parts, etc., which can solve problems such as clearance, easy movement of conveying roller 1001, inability to determine the static position of support 1003 of conveying roller 1001, etc. , to achieve the effect of improving landing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

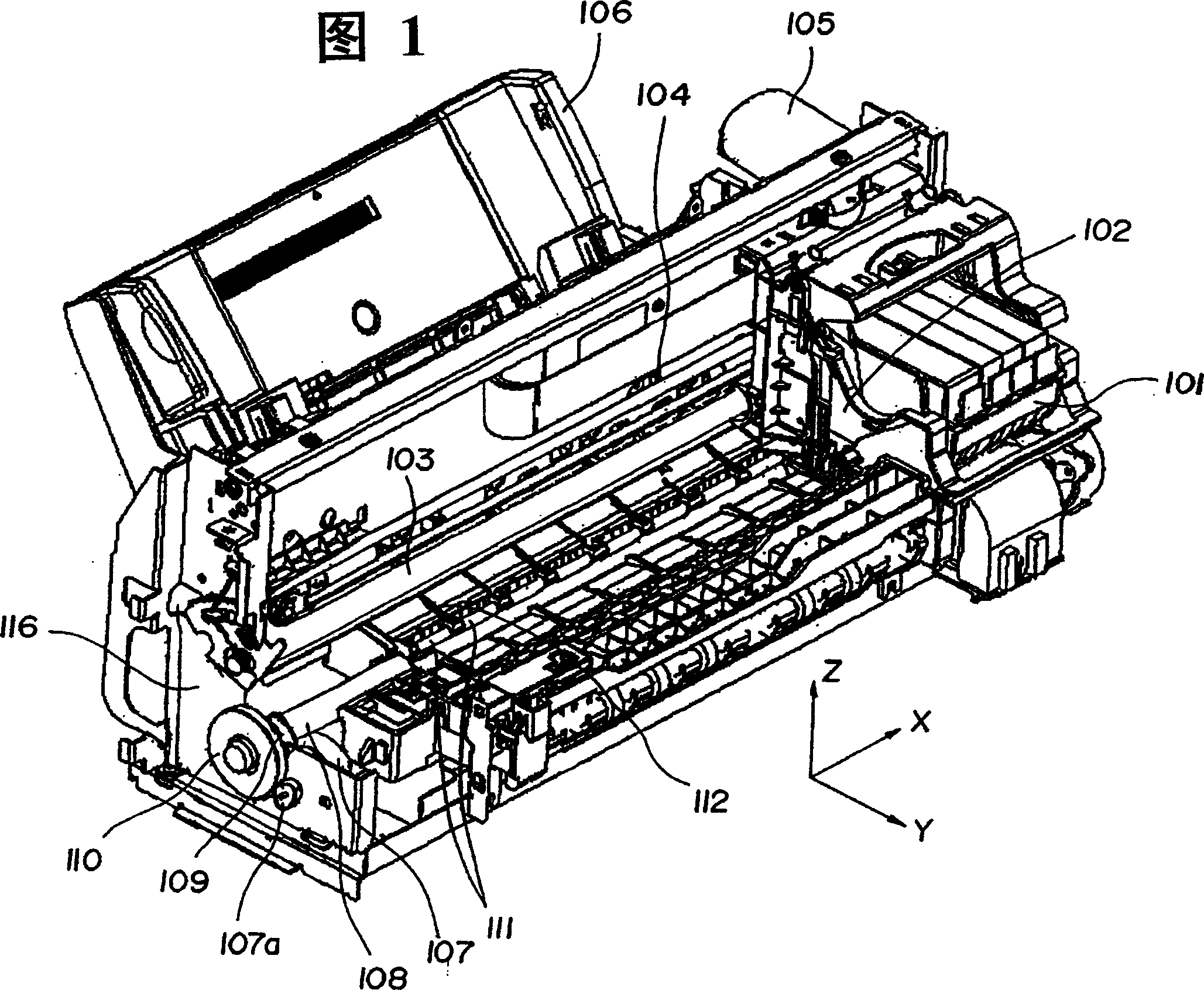

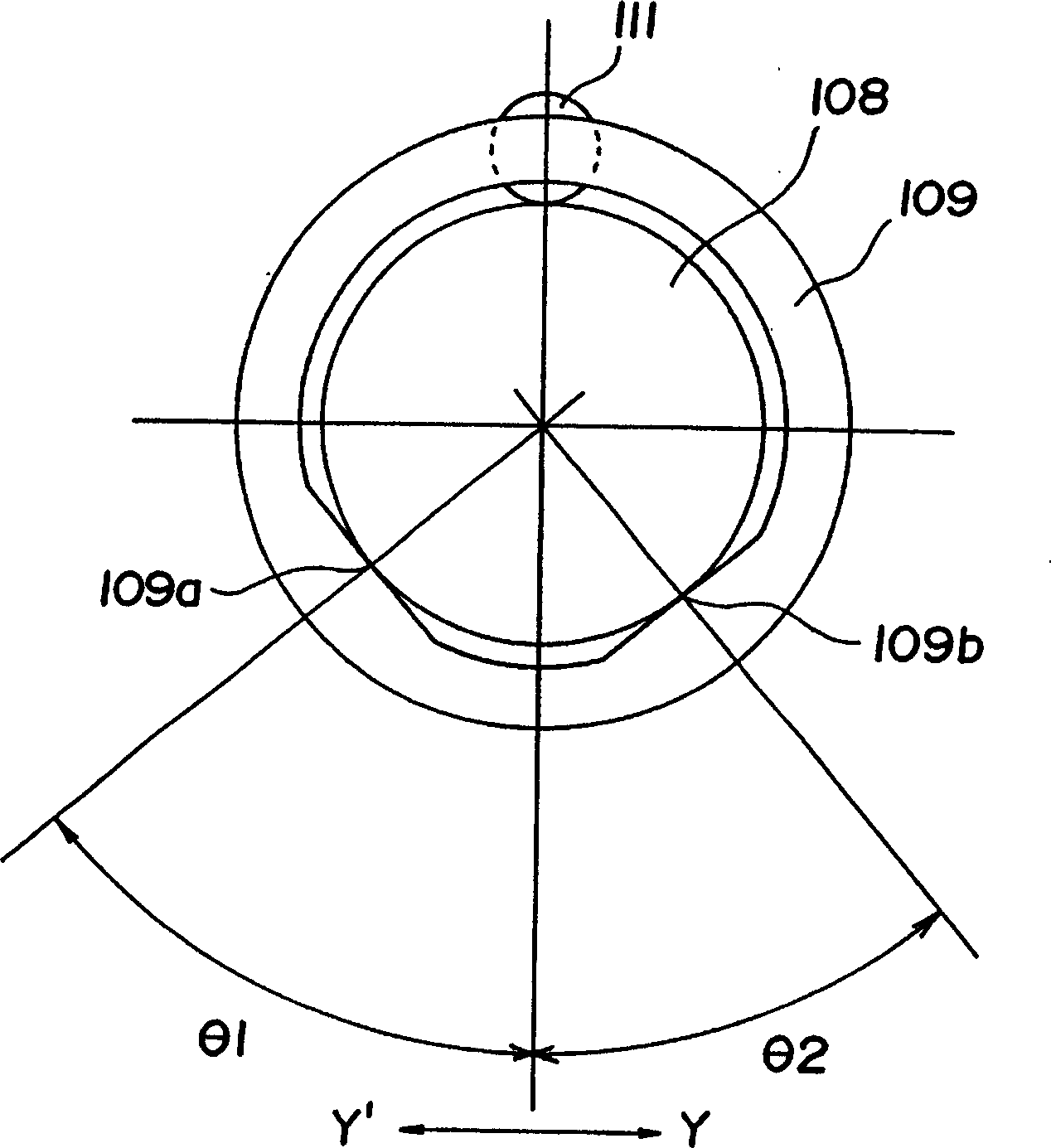

[0021] A description of the first embodiment is made. In this embodiment, a serial inkjet printer equipped with a recording head as a detachable recording device with an ink tank will be described as an example. FIG. 1 is an overall view of a serial inkjet printer. In FIG. 1 , 101 is a recording head having an ink tank, and 102 is a carriage of 101 on which the recording head is mounted. The guide shaft 103 is inserted into the bearing portion of the carriage 102 so as to be slidable in the main scanning direction perpendicular to the conveying direction of the recording medium 301 , and both ends of the shaft are fixed to the holder 116 . The carriage 102 is movable in the main scanning direction (X direction) by transmitting the drive of the driving motor 105 as the carriage driving means through the belt 104 as the carriage driving transmission means coupled to the carriage 102 .

[0022] In Fig. 1, 106 is a supply base storing recording media, 107 is a transport motor as...

no. 2 example

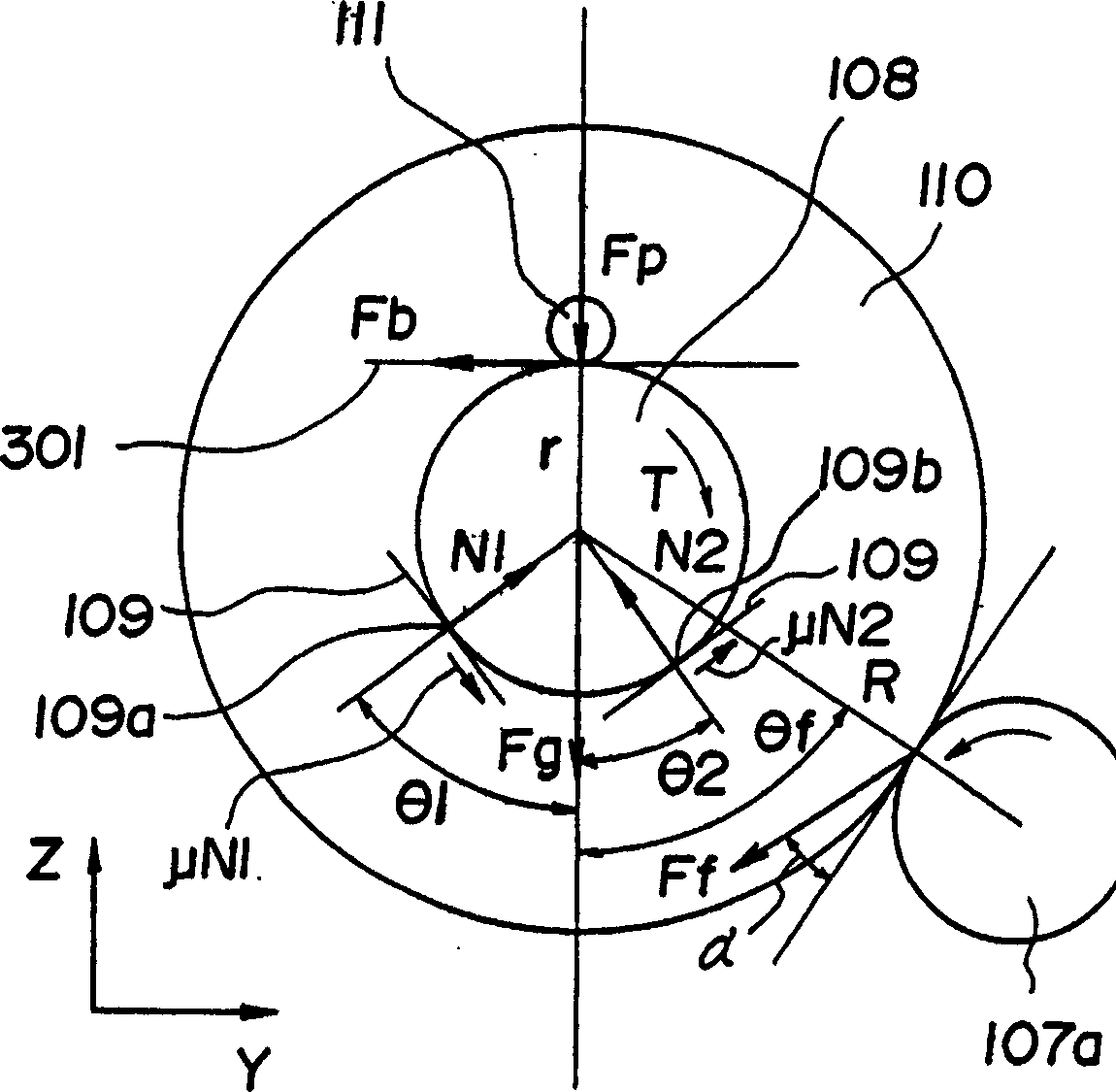

[0082] Figure 7 It is a structural diagram around the conveyance roller and bearings and a conceptual diagram of the acting force, showing the characteristics of the second embodiment of the present invention. Here, the same reference numerals as in the first embodiment have the same meanings. exist Figure 7 In the same manner as in the first embodiment, the conveying roller 108 is pivotally supported by the contact portions 109a and 109b on both surfaces of the bearing 109 . In addition, in this embodiment, the relationship between the bearing 109 and the support 116 is also similar by using the two-surface contact portions 116a, 166b of the support 116 to pivotally support the bearing 109 to eliminate the gap between the bearing 109 and the support 116. The determined position supports the bearing 109 on the support 116 .

[0083] Figure 7 The symbols in mean:

[0084] Ft: force acting on the bearing 109 by the transport roller 108 (Ft is an action vector obtained fr...

no. 3 example

[0095] For the third embodiment of the present invention, same as the second embodiment, Figure 9 A diagram showing the structure around the feed roller and bearings. Here, the same reference numerals as those in the first and second embodiments have the same meanings. In the third embodiment, the contact position angles θc1 and θc2 between the bearing 109 and the support 116 are set to be equal to the contact position angles θ1 and θ2 between the conveyor roller 108 and the bearing 109 obtained in the first embodiment. That is, the contact portions 109 a , 109 b of the bearing and the contact portions 116 a , 116 b of the holder 116 are set to exist on the same straight line passing through the center of the conveying roller 108 . In practice, usually because the mass of the bearing 109 is much smaller than that of the conveying roller 108, the influence of the gravity Fg2 of the bearing 109 can be ignored.

[0096] Therefore, the force received by the bearing 109 from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com