Magnetic recording medium and producing method thereof, magnetic recording and reproducing equipment

A magnetic recording medium and perpendicular magnetic recording technology, applied in the directions of magnetic recording, data recording, recording information storage, etc., can solve the problems of increasing the recording density, reducing the c-axis orientation of the perpendicular magnetic recording film, reducing the resistance to thermal fluctuation, etc. Effects of improved recording and reproduction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

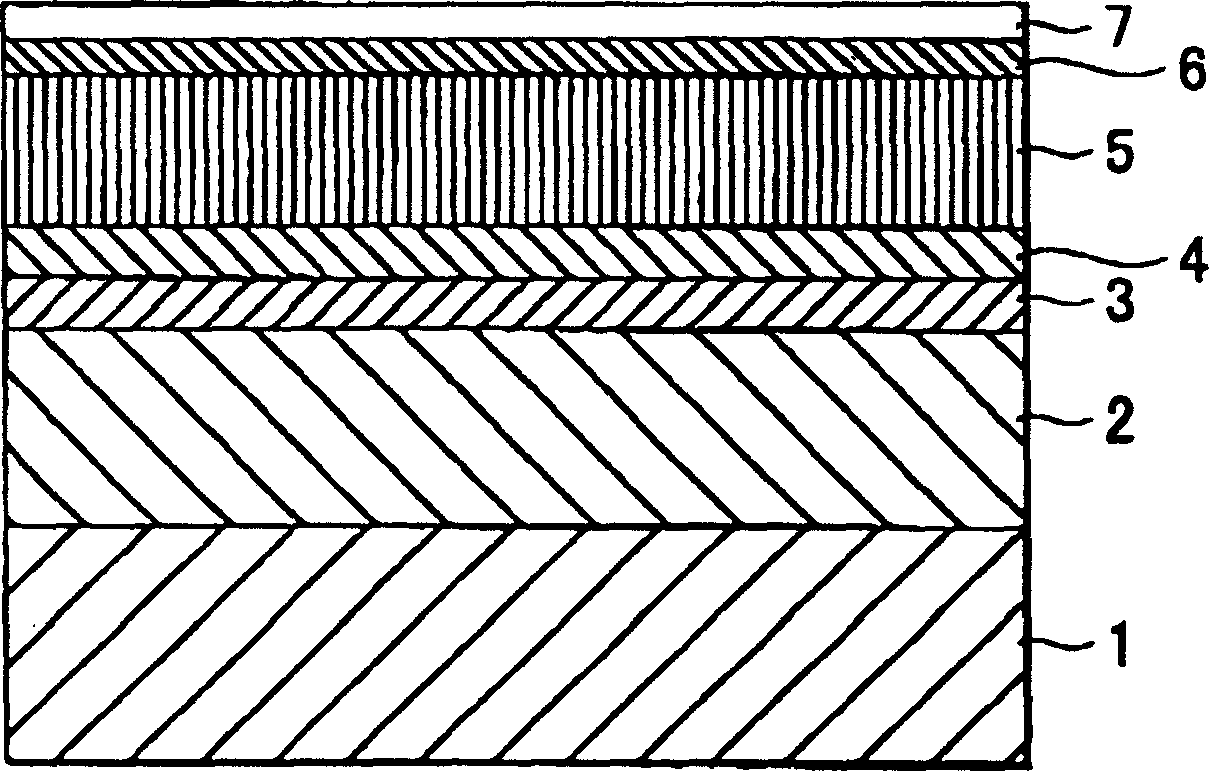

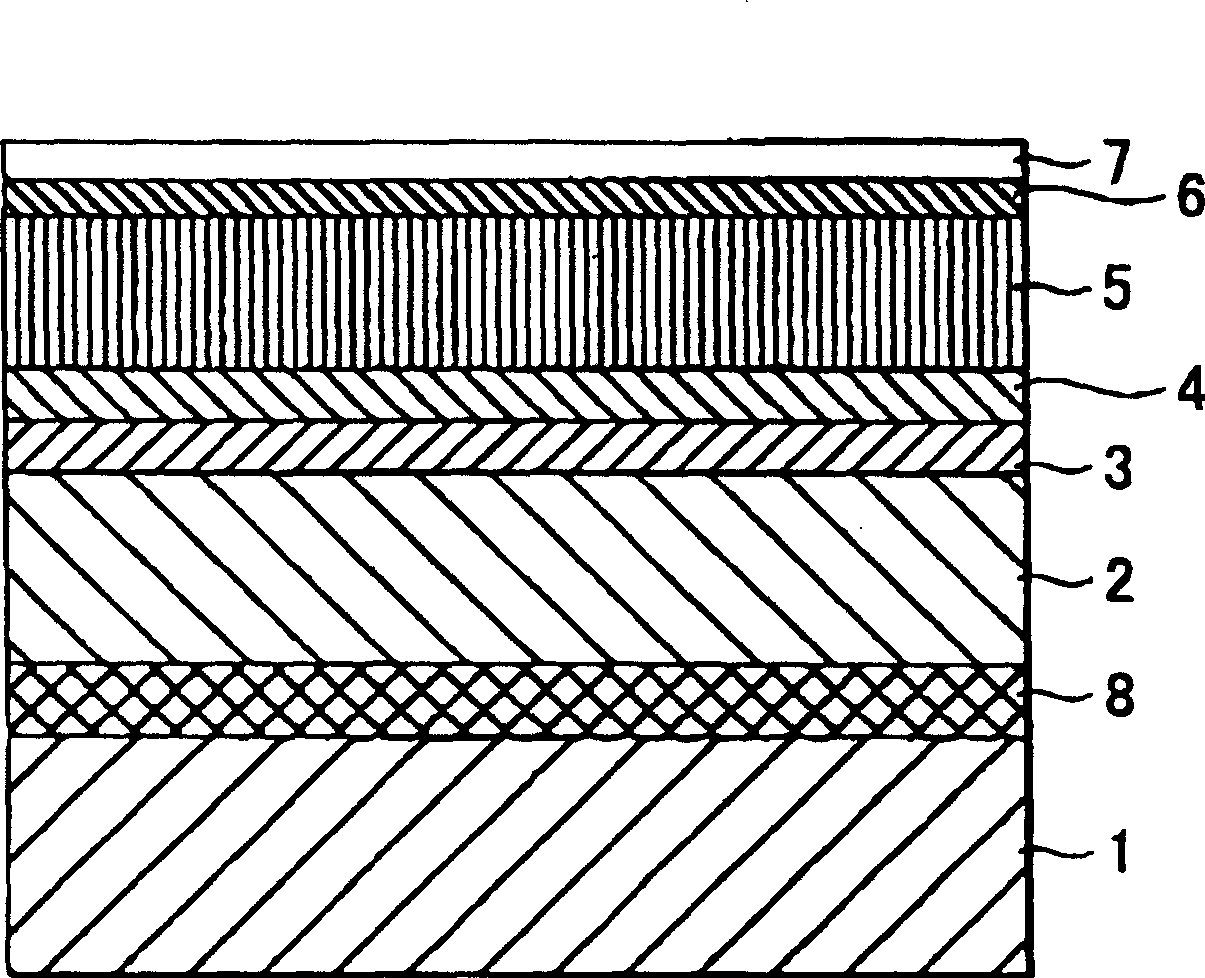

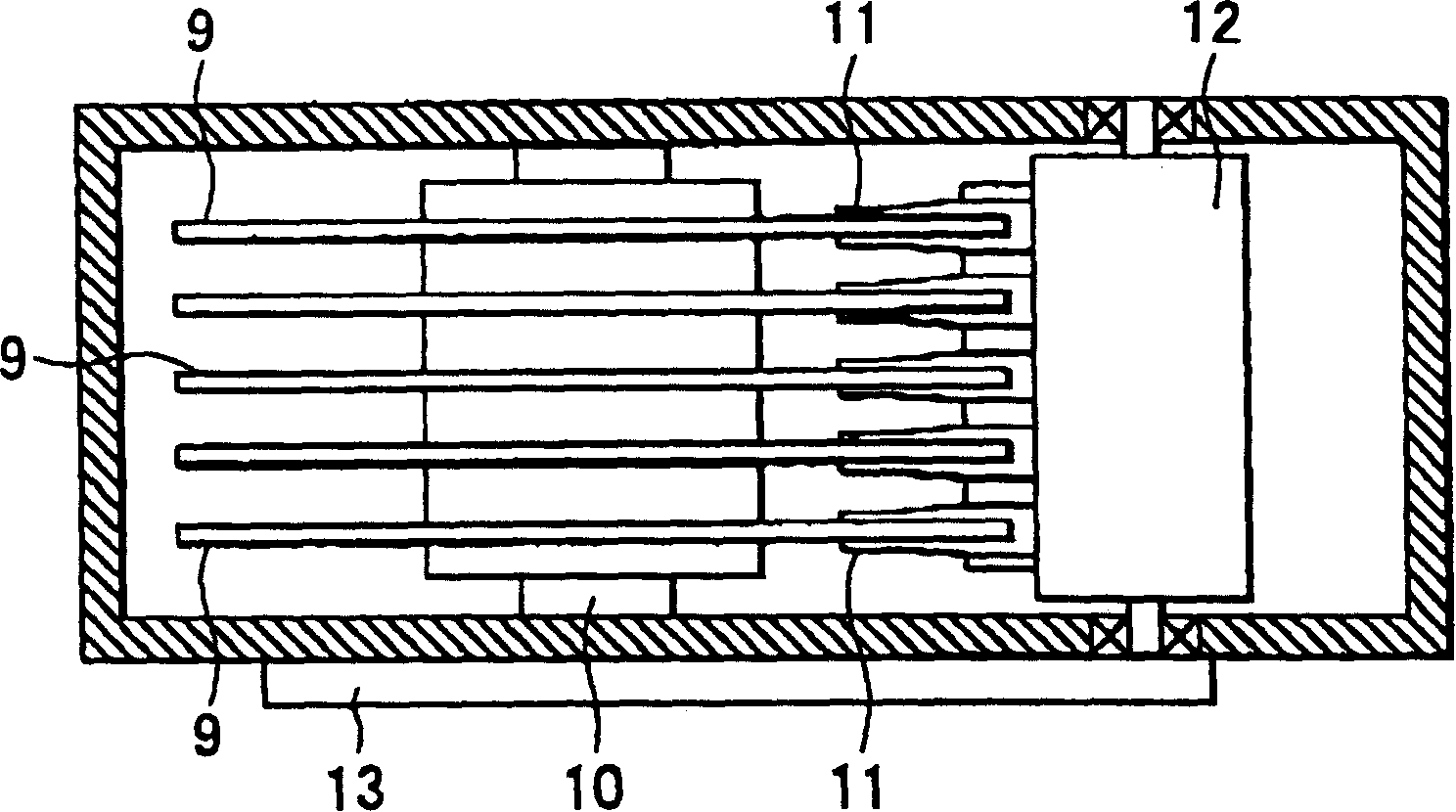

[0082] A washed glass substrate (produced by Ohara, Japan, 2.5 inches in outer diameter) was placed in the film forming chamber of a DC magnetron sputtering device (C-3010, produced by Anelva, Japan). Vacuum the film forming chamber until 1×10 -5 After Pa, using 89Co-4Zr-7Nb (Co content 89at%, Zr content 4at%, Nb content 7at%) target, the sputtering method was used to form a 160nm soft magnetic lower film 2 on the glass substrate. A vibrating sample magnetometer (VSM) was used to determine that the product Bs.t (T·nm) of the film's saturation magnetic flux density Bs(T) and the film thickness t (nm) was 200 (T·nm). Next, the substrate was heated to 240° C., and an 8 nm orientation control film was formed on the soft magnetic lower film 2 with a 33Cu-67Hf target. The saturation magnetization Ms of the film was determined to be 100 (emu / cc). Use 65Co-30Cr-5B (Co content 65at%, Cr content 30at%, B content 5at%) target to form a 10nm intermediate film 4, and then use 64Co-17Cr-17Pt-2B...

Embodiment 2-11

[0088] Example 1 was used as the basis for manufacturing magnetic recording media in Examples 2-11, except for the components of the orientation control film listed in Table 2. For comparison, let the intermediate film and the perpendicular magnetic recording film have the same composition and thickness.

[0089] Soft magnetic film

[0090] It is clear from Table 2 that the magnetic recording media of Examples 2-11 showed outstanding recording and reproducing characteristics, and the orientation control film in these magnetic recording media had C11 b The composition of the structure.

Embodiment 12-16

[0092] Example 1 was used as the basis for manufacturing magnetic recording media in Examples 12-16, except for the thickness of the orientation control film as listed in Table 3. For comparison, let the orientation control film have the same composition. In addition, let the soft magnetic lower film, the intermediate film and the perpendicular magnetic recording film have the same composition and thickness.

[0093] Soft magnetic film

Orientation control film

Interlayer

Perpendicular magnetic recording film

Recording / reproduction characteristics

Component

Bs×1

(T·nm)

Component

(at%)

Thickness

(nm)

Component

(at%)

Thickness

(nm)

Component

(at%)

Thickness

(nm)

Error rate

(10 x )

Example 1

CoZrNb

200

33Cu-67Hf

5

65Co-30Cr-5B

10

64Co-17Cr-17Pt-2B

20

-5.8

Example

12

CoZrNb

200

33Cu-67Hf

0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com