Hero-turbine centrifuge with drainage enhancing baffle devices

A technology of centrifuge and liquid outlet, which is applied to centrifuges and centrifuges with rotating drums, etc., can solve the problems of unusable centrifuges and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] To facilitate an understanding of the principles of the invention, reference is made to the embodiments illustrated in the drawings and specific terminology is used to describe the same structures. It should be understood, however, that the scope of the invention is not thereby limited in any way, and those skilled in the art to which the invention pertains contemplate similar alterations and further modifications to the devices described and in accordance with the principles of the invention as described. Further applications are usually possible.

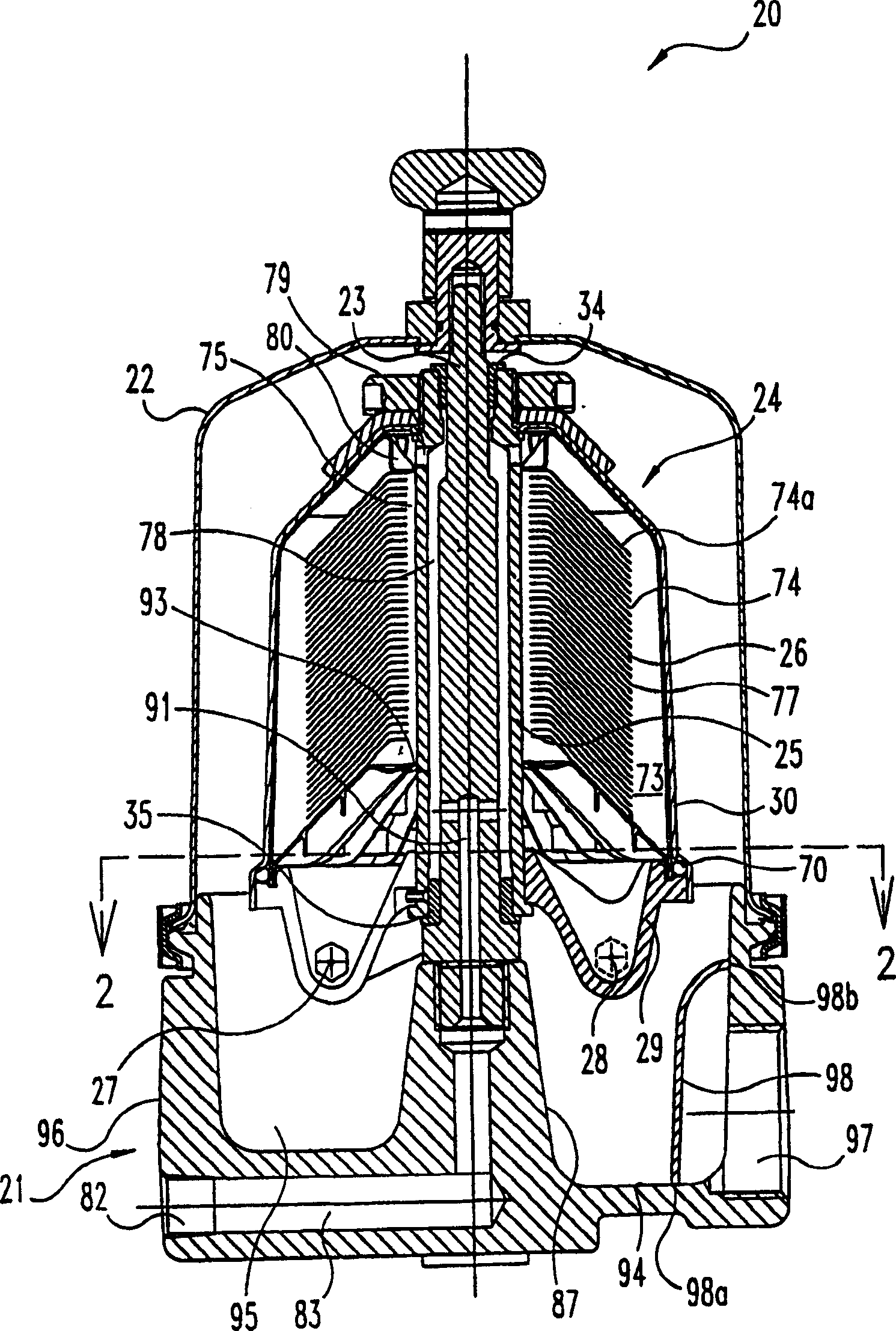

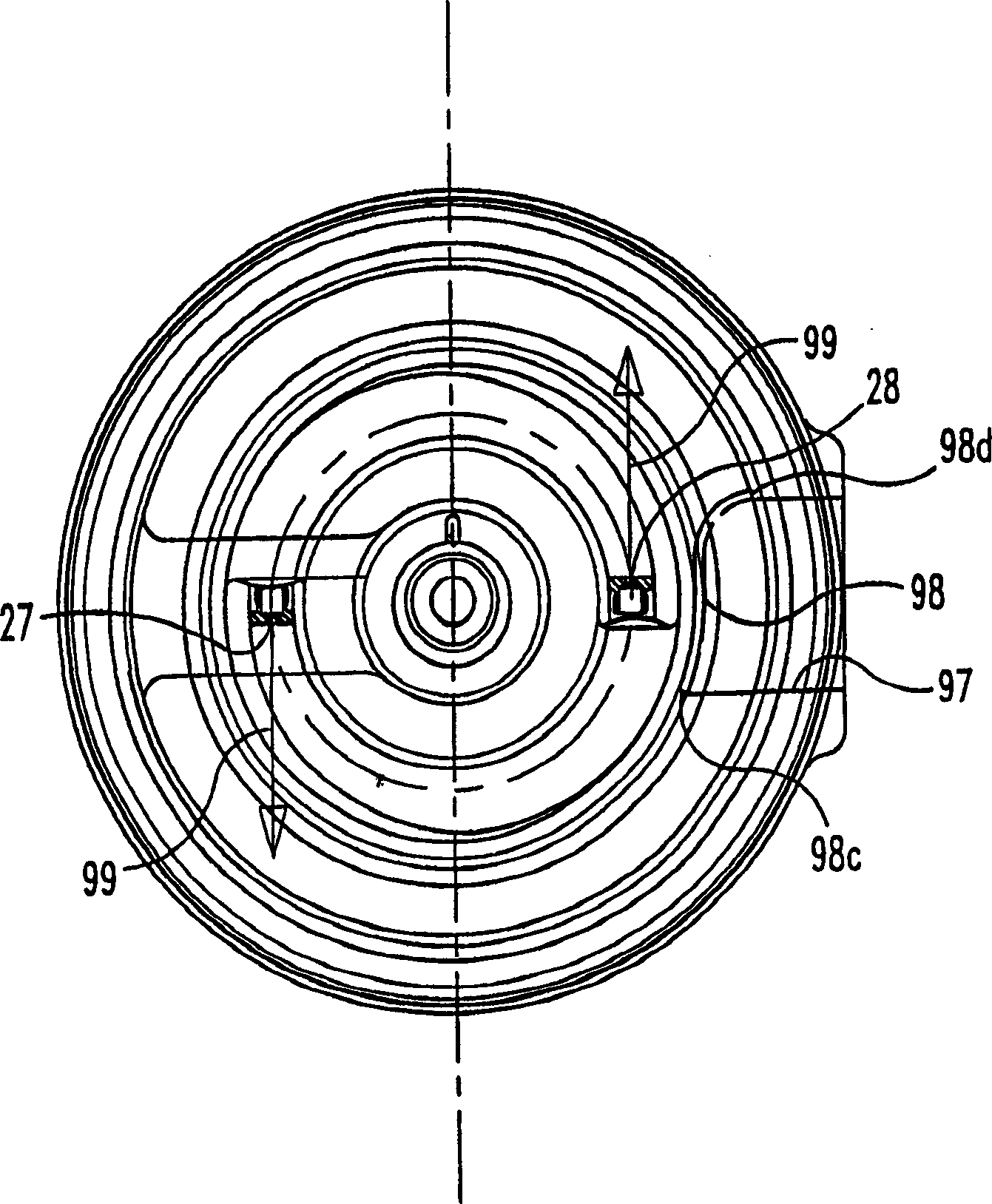

[0016] see figure 1 , which shows a stacked cone centrifuge 20 according to a preferred embodiment of the present invention. The centrifuge 20 includes, as its main components, a base 21, a bell 22, a shaft 23 and a rotor assembly 24 including a rotor hub 25, a stack of cones 26, tangential flow nozzles 27 and 28 , a bottom plate 29 and a centrifuge bowl 30 closed on the bottom plate 29 in a fixed manner. A hollow rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com