Pneumatic self sucking high-pressure oil ejector

A high-pressure oil injection, self-priming technology, applied in the direction of engine components, engine lubrication, mechanical equipment, etc., can solve the problems affecting the pressure value of the oil injection port, the pressure of the oil injection port is unstable, and the maintenance amount is large. Simple, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

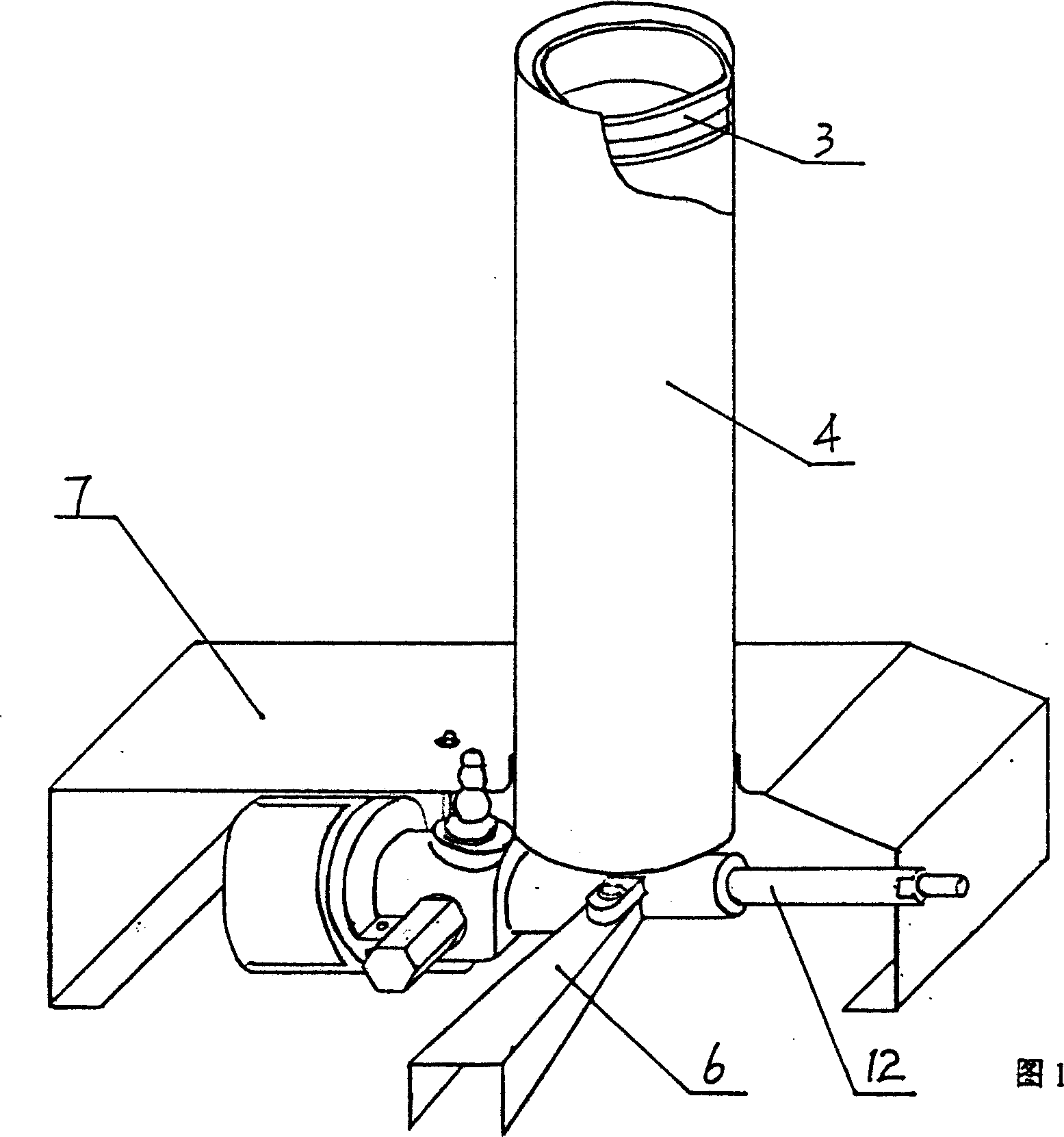

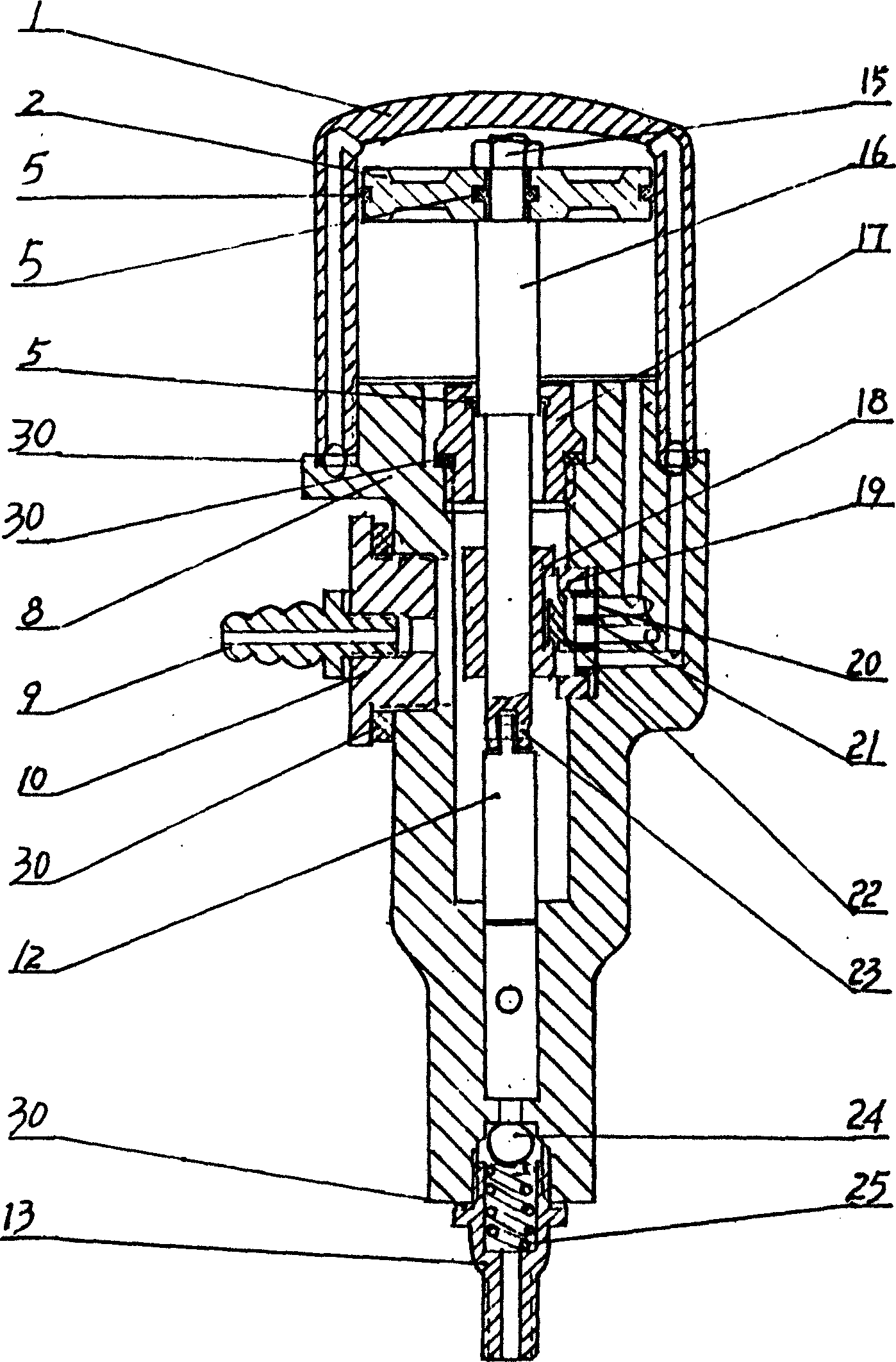

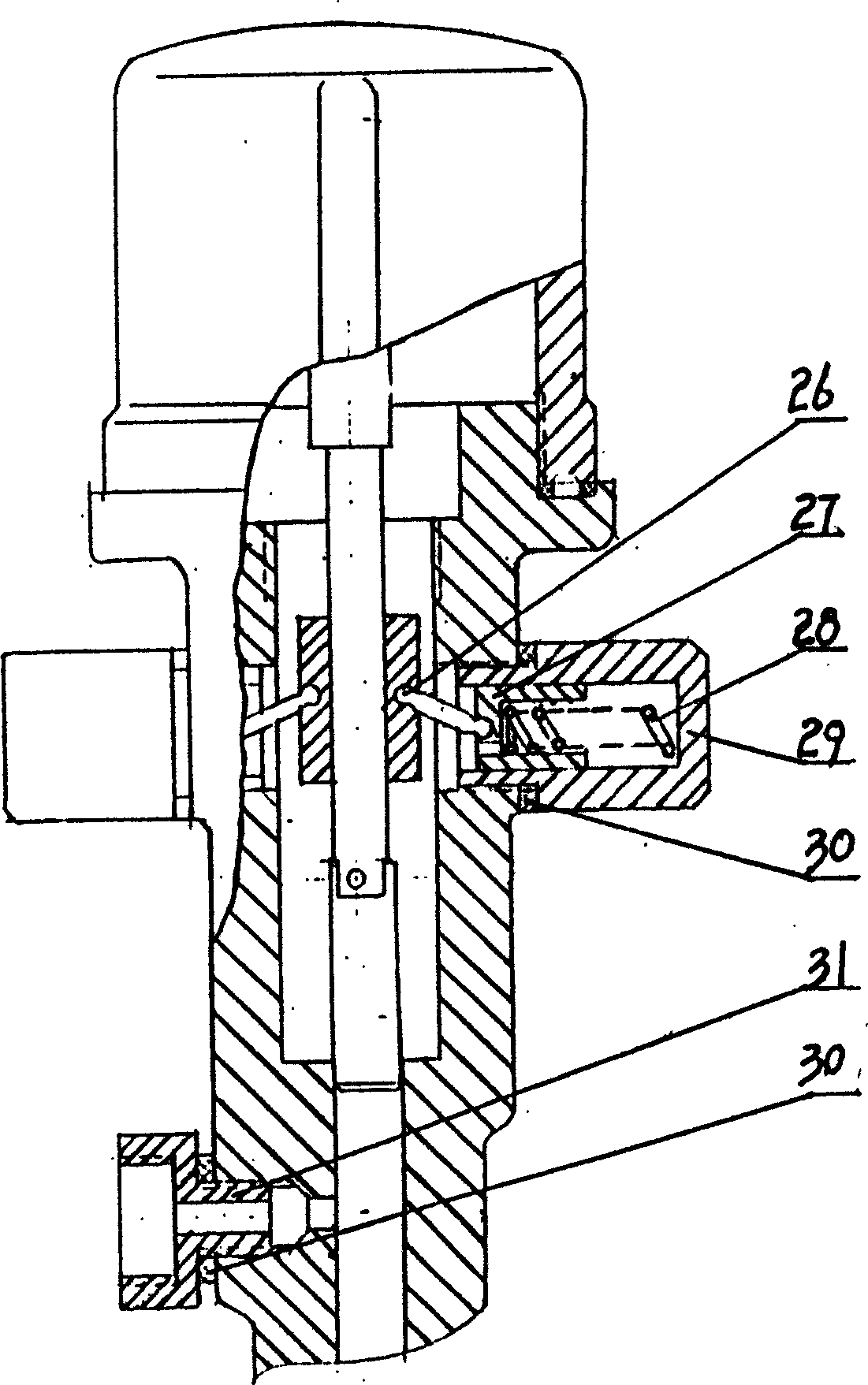

[0021] As shown in Figures 1, 2, and 3, the present invention includes an oil storage mechanism and an oil injection mechanism, wherein the oil storage mechanism is composed of an oil storage cylinder 4 and a large piston 3, the oil injection mechanism is composed of a plunger 12 and a check valve, and the plunger 12 There is a space between one end and the check valve; it also includes an aerodynamic mechanism and an action program control mechanism, which are installed in the box 7; the aerodynamic mechanism is connected to the compressed air source through the compressed air interface 9, and is connected to 16 is connected with the plunger 12 in the oil injection mechanism; the action program control mechanism is installed on the middle part of the valve body 8 and the moving rod 16 in the aerodynamic mechanism; In the power mechanism, the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com