Novel valve plate for balancing overturning moment

A technology of overturning moment and distribution plate, which is applied to components of pumping devices for elastic fluids, liquid variable displacement machinery, variable displacement pump components, etc. It can solve the problem of force imbalance, vibration and noise, Complex structure and other problems, to reduce oil pressure, prevent oil leakage, and avoid oil source leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

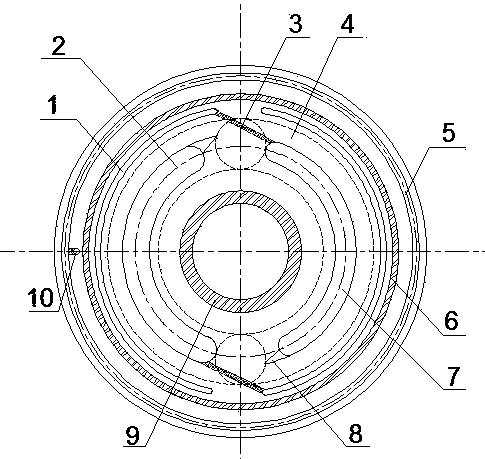

[0016] Such as figure 1 Shown is a new distribution plate that balances the overturning moment, and uses the oil passage between the high-pressure oil chamber 2 and the small oil hole 10 to introduce the pressure oil in the high-pressure oil chamber 2 into the static pressure support groove 5 through the small oil hole 10 , and the oil hole 10 is connected by the damping groove and the static pressure support groove 5. The working principle of this continuous oil supply distribution structure is that the high pressure oil in the plunger chamber passes through the oil passage opened during the rotation of the cylinder body. It flows into the small oil hole 10, and flows into the static pressure support groove 5 through the damping groove, so that a reverse thrust greater than the pressing force is established between the friction pairs to make the cylinder float, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com