Rotation detection sensor

A technology for detecting sensors and detected objects, which is applied to measuring instrument components, instruments, and electric/magnetic devices to transmit sensing components, etc., and can solve problems such as deterioration of wires, poor sealing of wheel speed sensors 110, and decline in detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

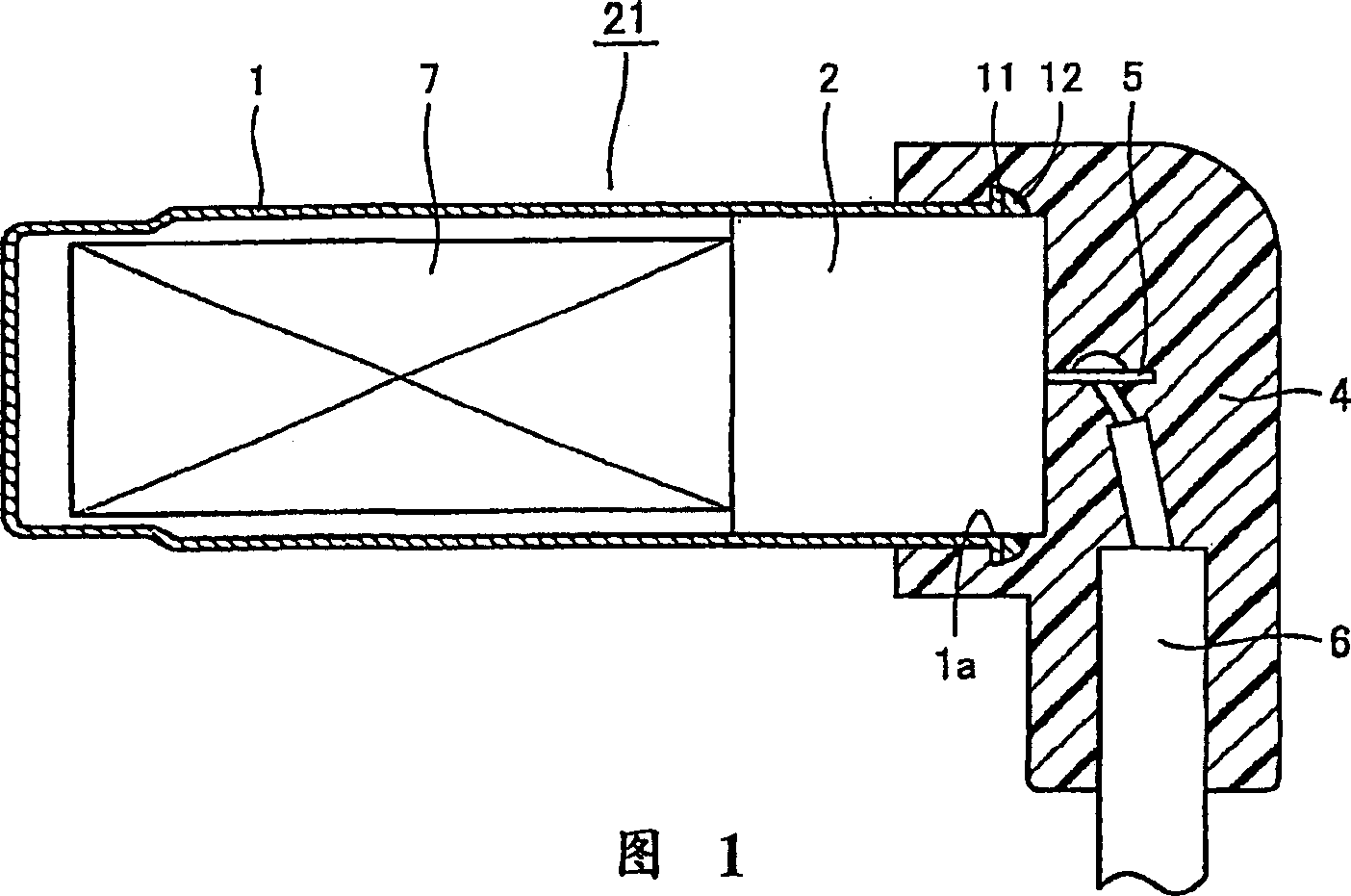

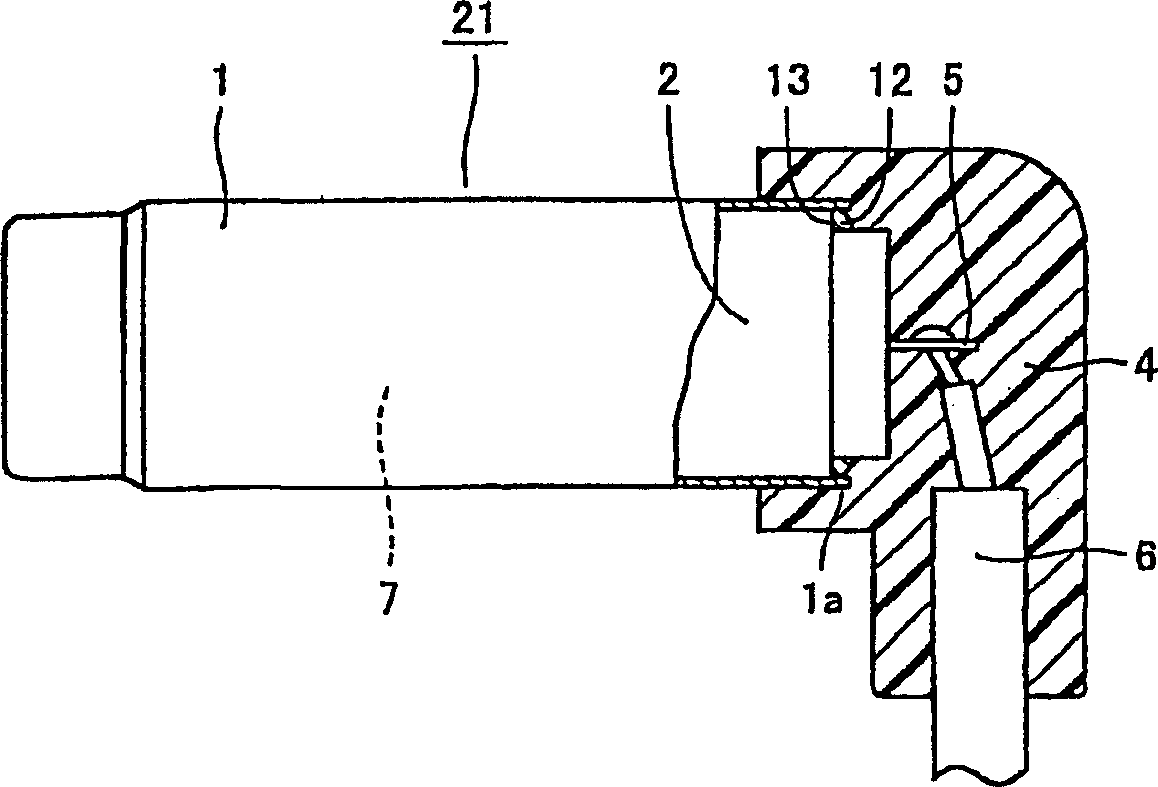

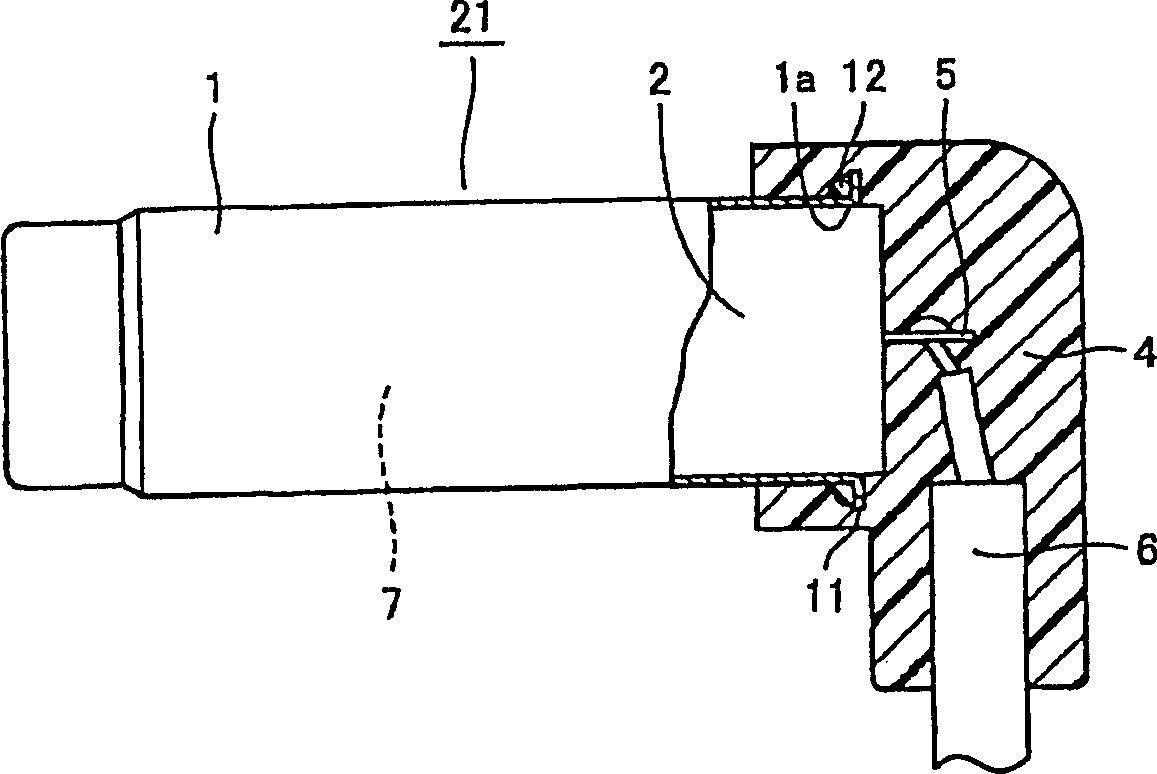

[0025] A rotation detection sensor according to an embodiment of the present invention will be described. The rotation detection sensor detects the change of the magnetic field generated by the rotation of the object to be detected by the detection part, and converts it into an electric signal. The detection part is installed on the bracket. The detection unit is inserted through the opening of the capped cylindrical sleeve and attached to the cap side. The bracket part fits into the opening part.

[0026] The portion between the edge of the opening and the bracket is filled with a synthetic rubber-based solvent-based sealant over the entire circumference. Furthermore, the edge of the opening and the holder are covered with a resin part.

[0027] As the synthetic rubber-based solvent-based sealant, a viscoelastic liquid gasket can be used, for example, a viscoelastic liquid gasket manufactured by Sumitomo Triem Co., Ltd. or a viscoelastic liquid gasket manufactured by Semed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com