Connecting mechanism of tape drive wheel electric machine for tape recorder

A tape recording and electrical connection technology, applied in the direction of record carrier drive mechanism, record carrier structural parts, data recording, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

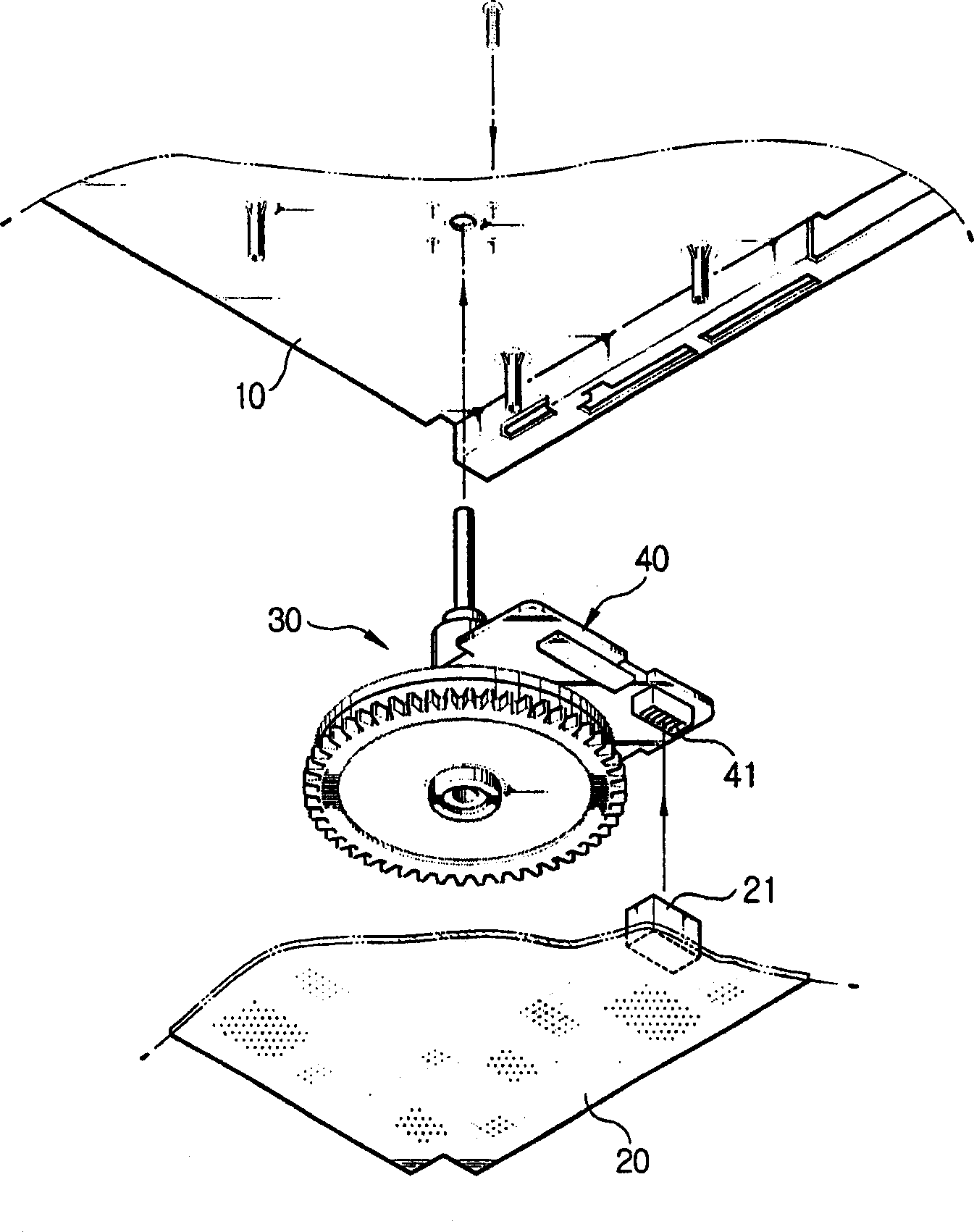

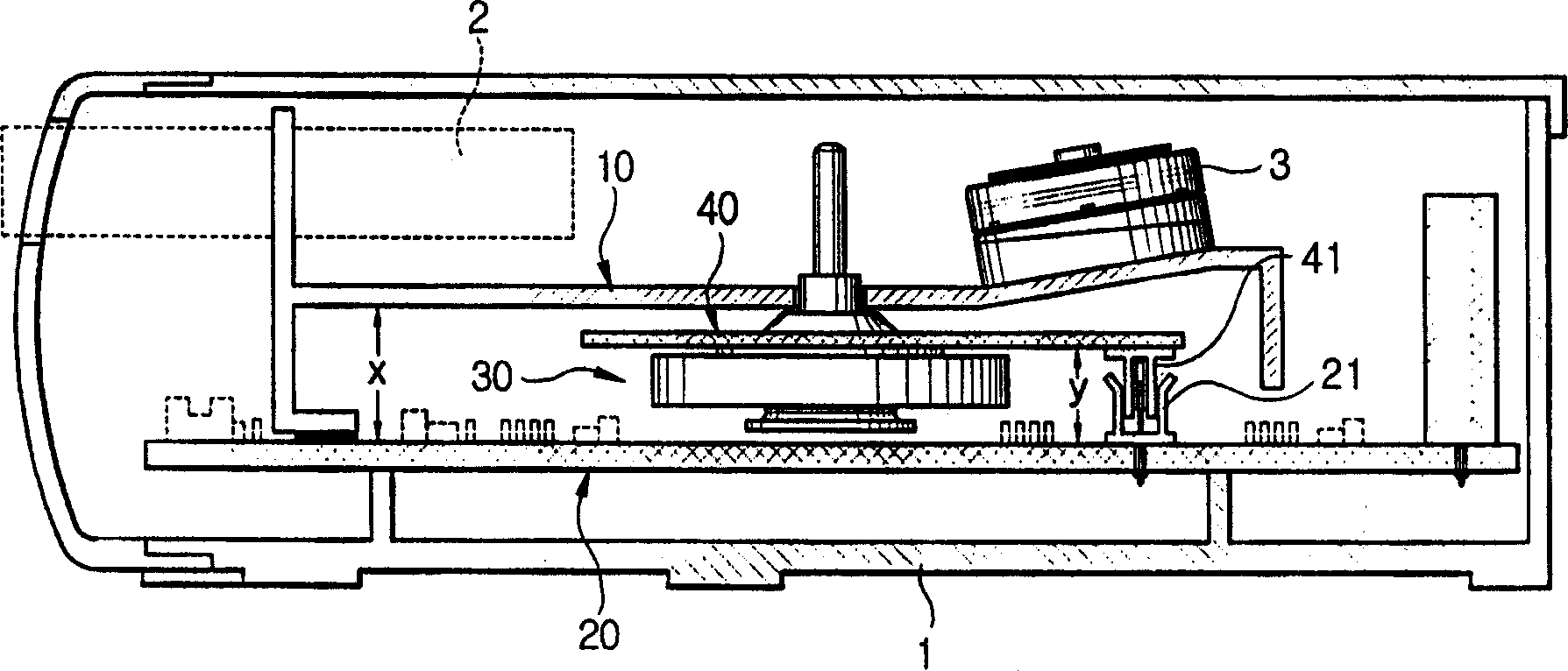

Image

Examples

Embodiment Construction

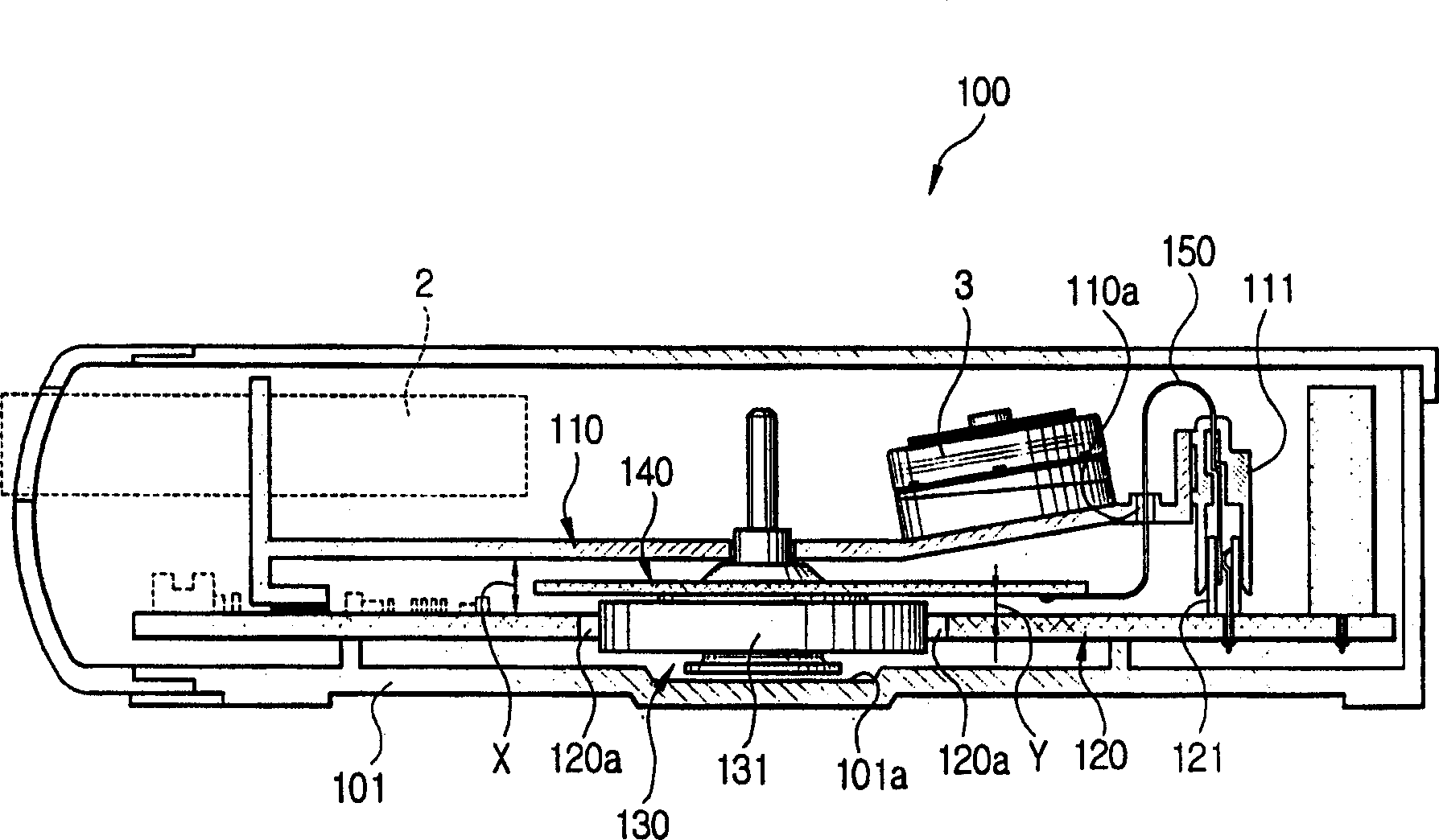

[0019] refer to Figures 3 to 5 , the magnetic tape recorder 100 having the connection structure of the reel motor according to an embodiment of the present invention includes a first connector 121 electrically connected to the main PCB 120; The second connector 111 on the connector 121; the support hole 110a formed in the main base 110; and the cable 150 penetratingly supported in the support hole 110a for electrically connecting the slave PCB 140 of the reel motor 130 to on the second connector 111. Also, the main PCB 120 has a hole 120a formed therein, and the reel motor 130 is embedded relative to the main PCB 120, and the main body 131 of the reel motor 130 is placed in the hole 120a so that the distance X between the main substrate 110 and the main PCB 120 decreases. Small. In this example, reference numerals 101, 2, and 3 denote a case, a cassette, and a head drum, respectively.

[0020] According to the above structure, the distance X between the main substrate 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com