System and methods for sensing acoustic signal using micro-electronical system technology

A signal and sound system technology, applied in the field of micro-electromechanical system technology to sense sound signals, can solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

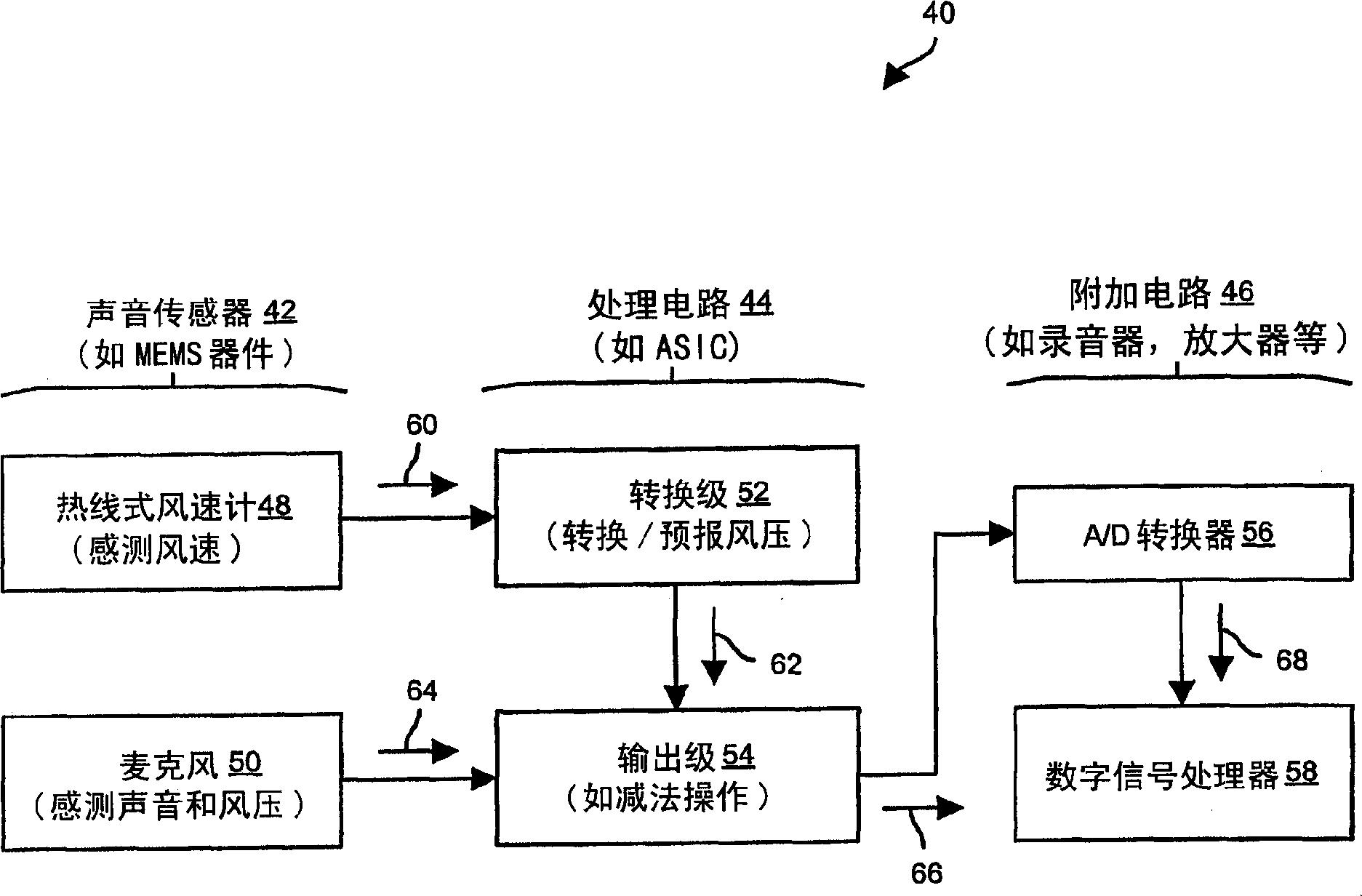

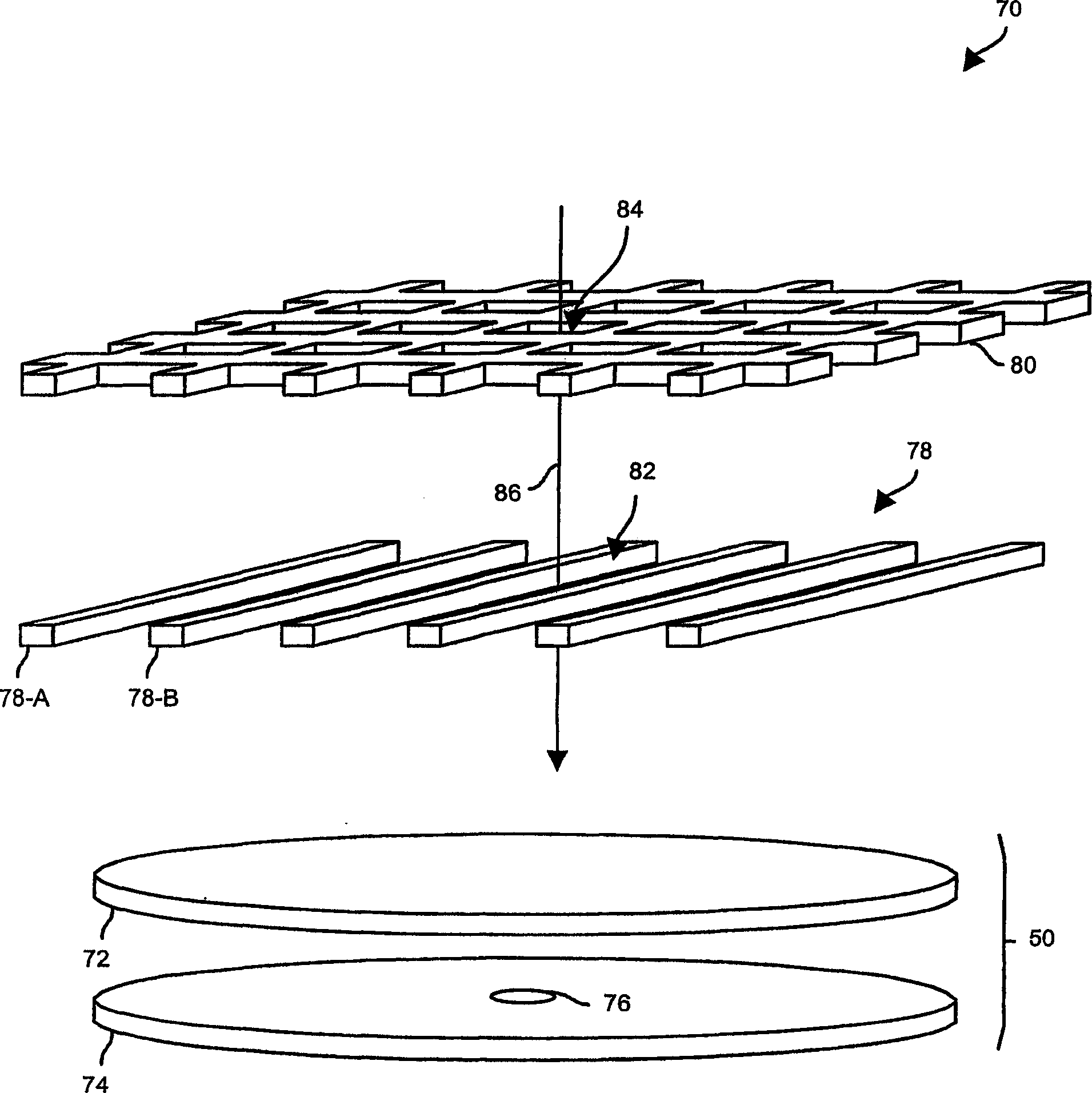

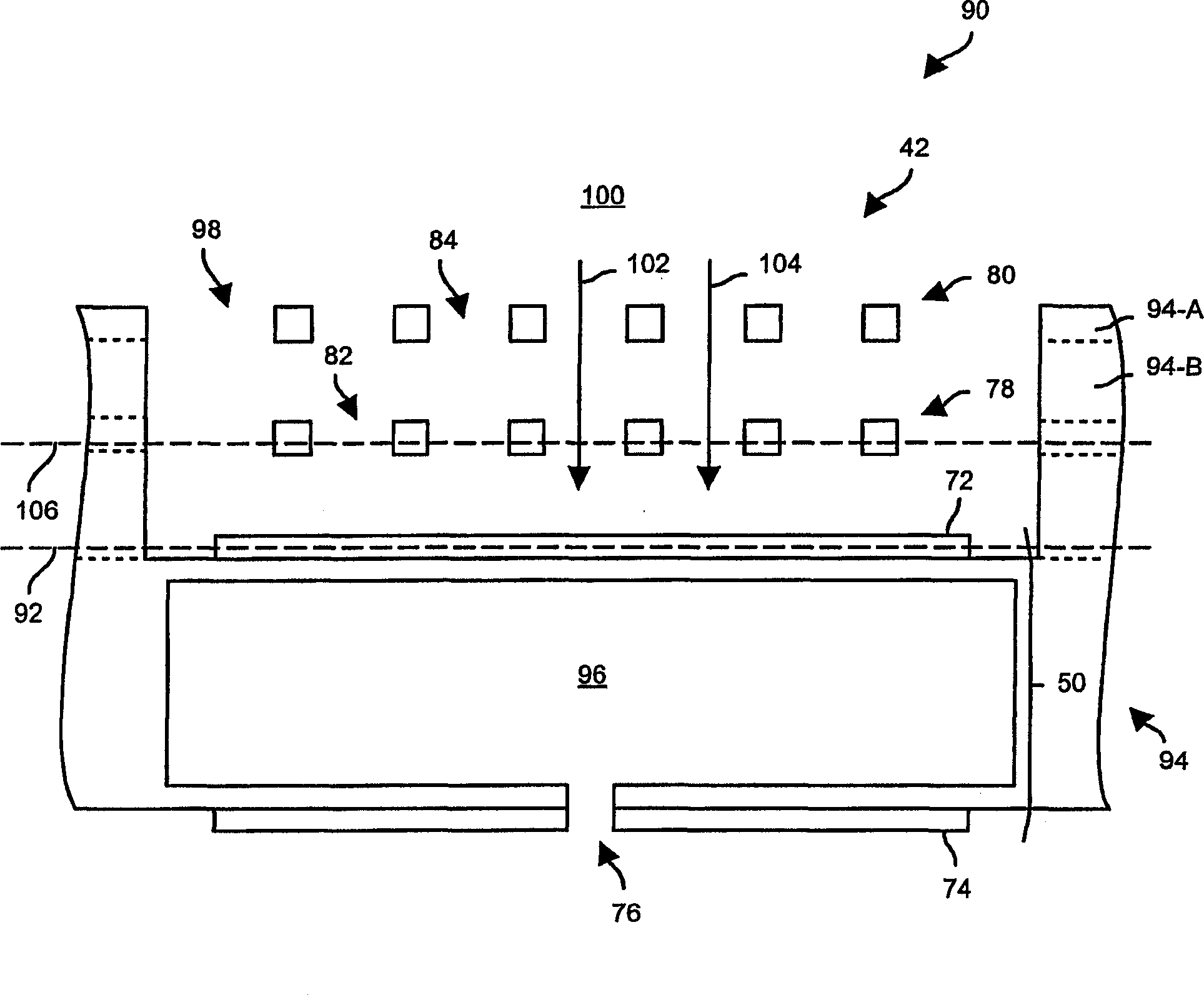

[0064] Embodiments of the present invention relate to methods of obtaining acoustic signals using Micro Electro Mechanical Systems (MEMS) technology. For example, sensing components such as microphones and hot wire anemometers may be disposed within the MEMS device (eg, may be arranged at one location with limited precision separation). Therefore, wind speed, sound and wind pressure can be measured at almost the same location. As a result, a wind pressure signal is generated based on the wind speed at that location, and the generated wind pressure signal is then subtracted from the sound and wind pressure signals at that location, thereby providing an accurate sound signal with wind noise removed.

[0065] figure 1 is a block diagram of an audio transmission system 40 suitable for use with the present invention. The acoustic transmission system 40 includes an acoustic sensor 42 and a processing circuit 44 . The audio transmission system 40 also includes additional circuitry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com