Method for manufacturing skid-proof flat iron

A technology of manufacturing device and manufacturing method, which is applied in the field of manufacturing and device of anti-slip flat iron, and can solve problems such as skidding, pedestrian or vehicle safety threat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

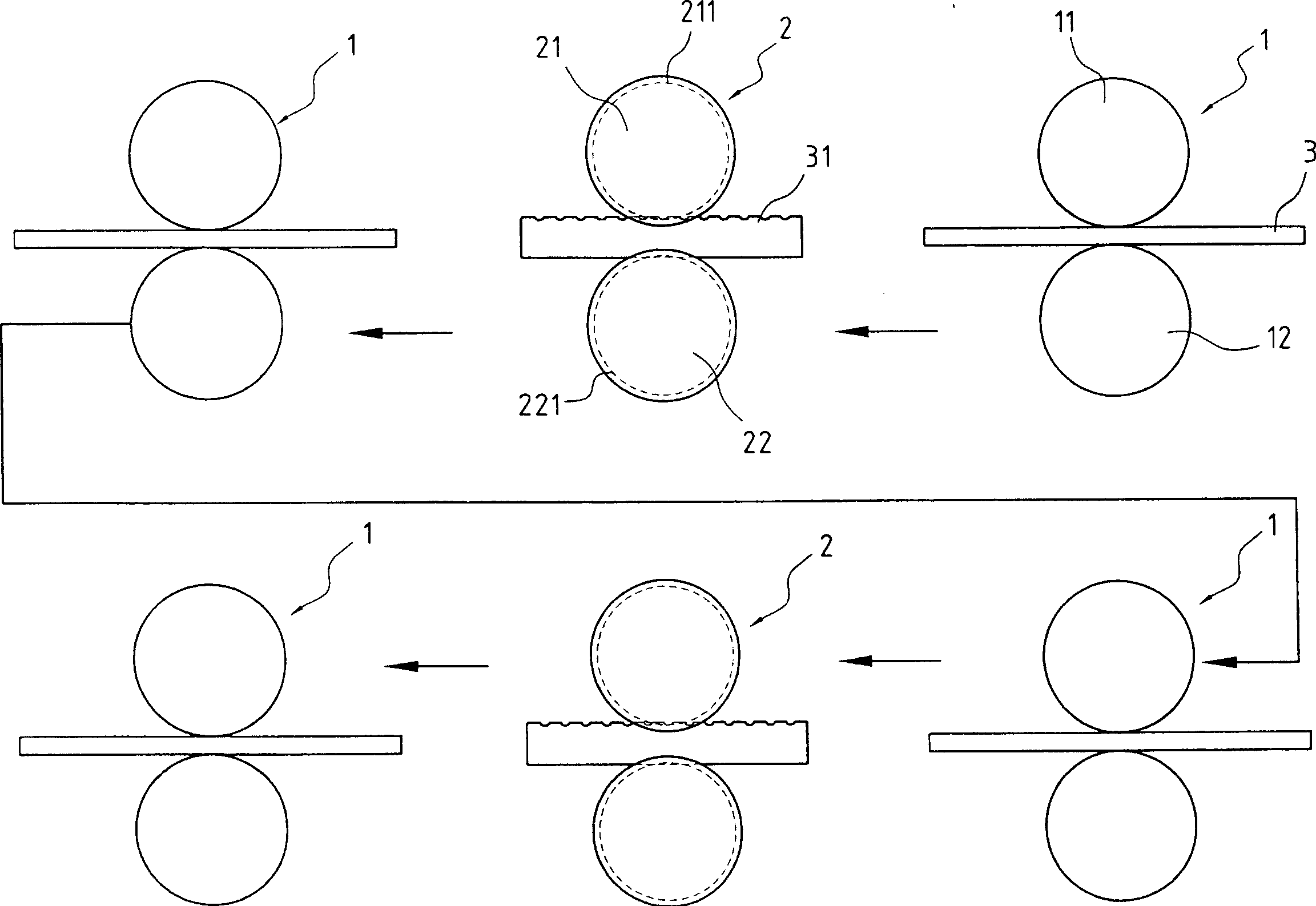

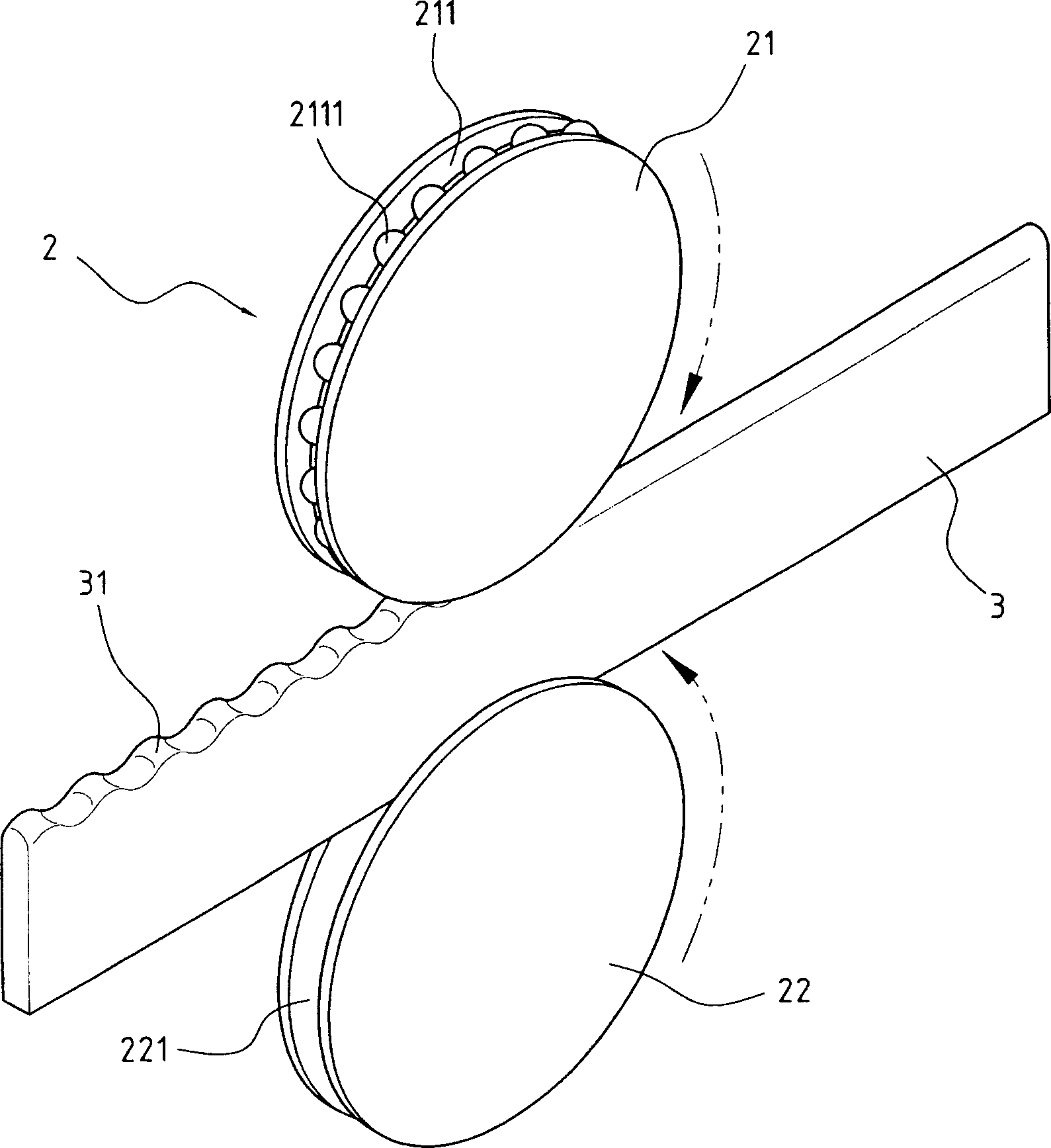

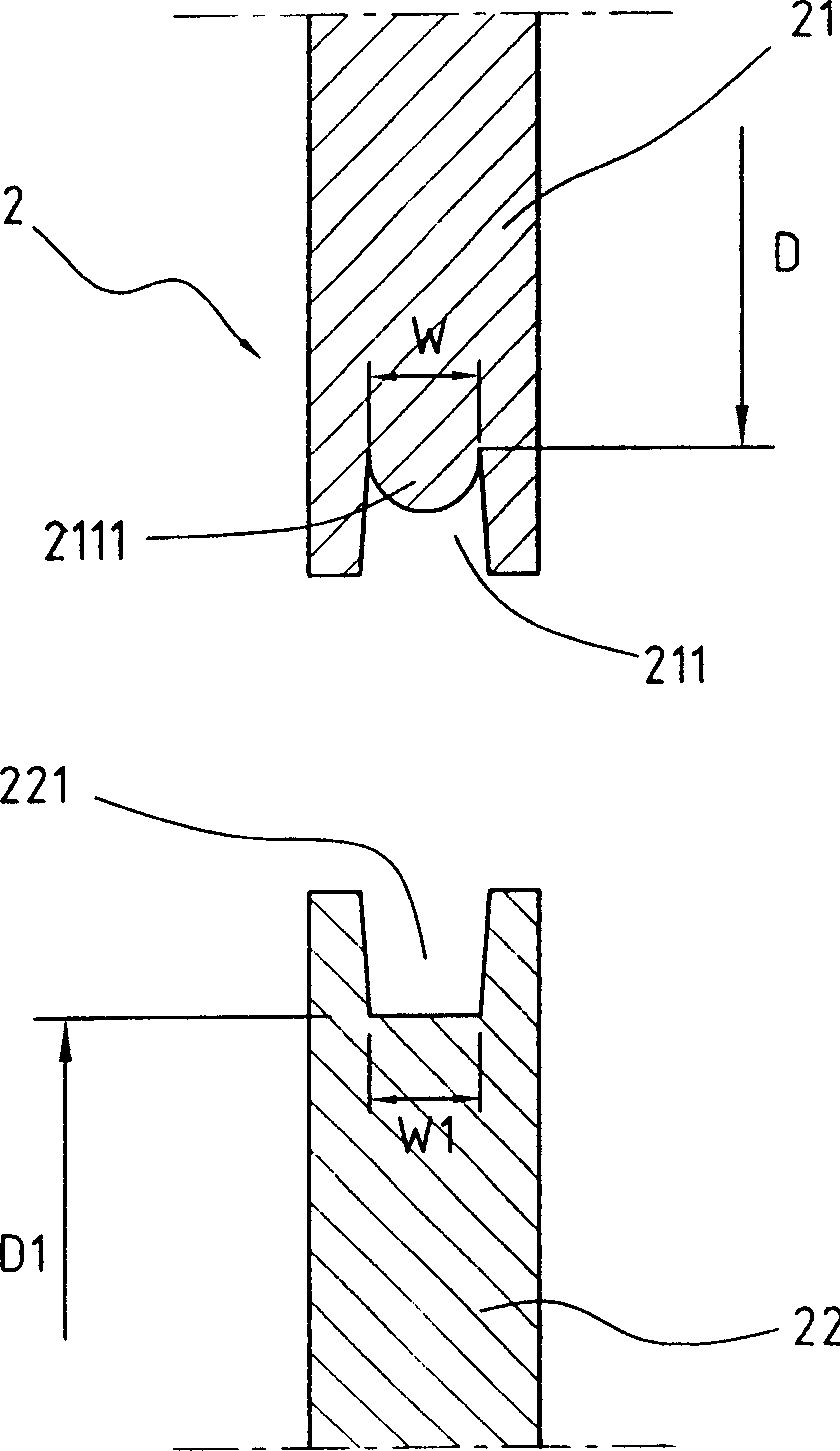

[0026] Such as figure 1 As shown, the first anti-slip iron manufacturing method and device provided by the present invention, its manufacturing process is that when the iron material 3 is heated to the working temperature, the iron material 3 is transported by means of conveying equipment (not shown in the figure) Through the calendering roller group 1 and calendering roller group 2 arranged at intervals in series, the iron material 3 is flattened horizontally by the calendering roller group 1 with a flat wheel surface, and then the iron material 3 is passed through the calendering roller group 2 The iron material 3 is guided by means of the annular grooves 211, 221 provided on the wheel surfaces of the upper and lower rollers 21, 22 of the calendering roller group 2, and the series of forming teeth 2111 arranged at the bottom of the annular groove 211 of the upper roller 21 are used to guide the iron material 3 One side of the iron material 3 is rolled to form protruding teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com