Gyrotron and angular velocity sensor

A technology of vibrating gyroscope and vibrating body, which is applied in the direction of gyro effect for speed measurement, gyroscope/steering sensing equipment, instruments, etc., which can solve the problems of increasing the number of parts, increasing the cost, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] first preferred embodiment

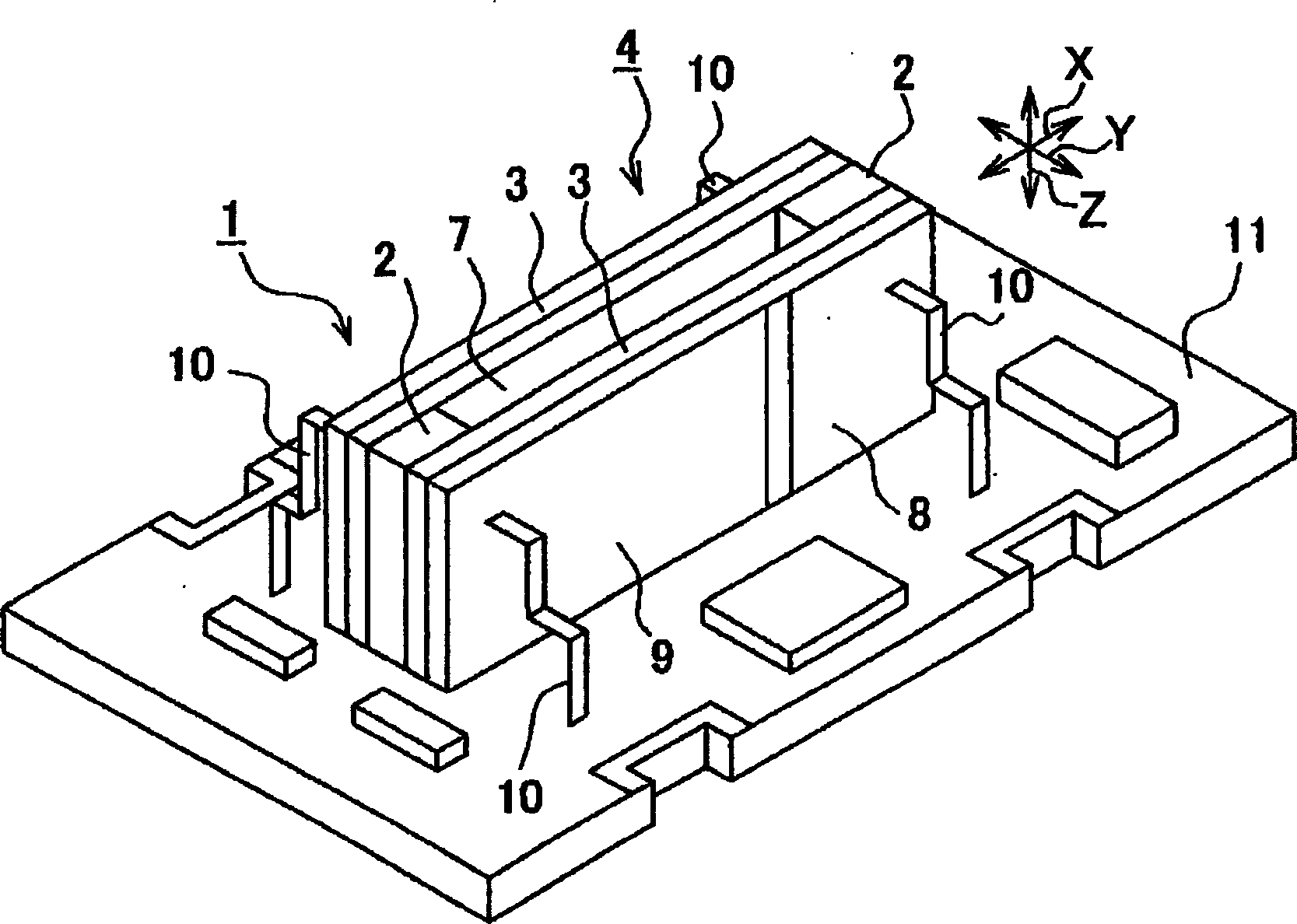

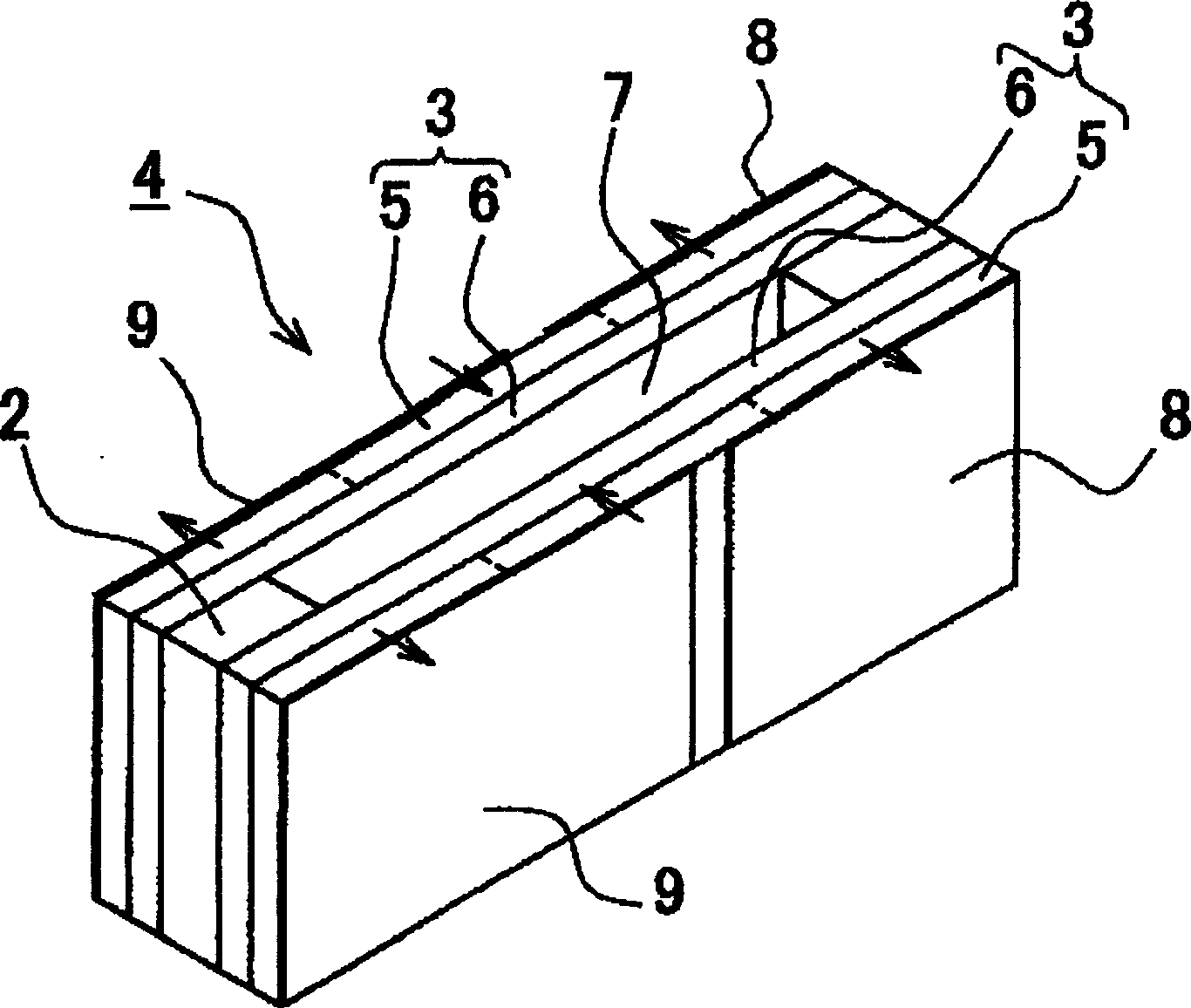

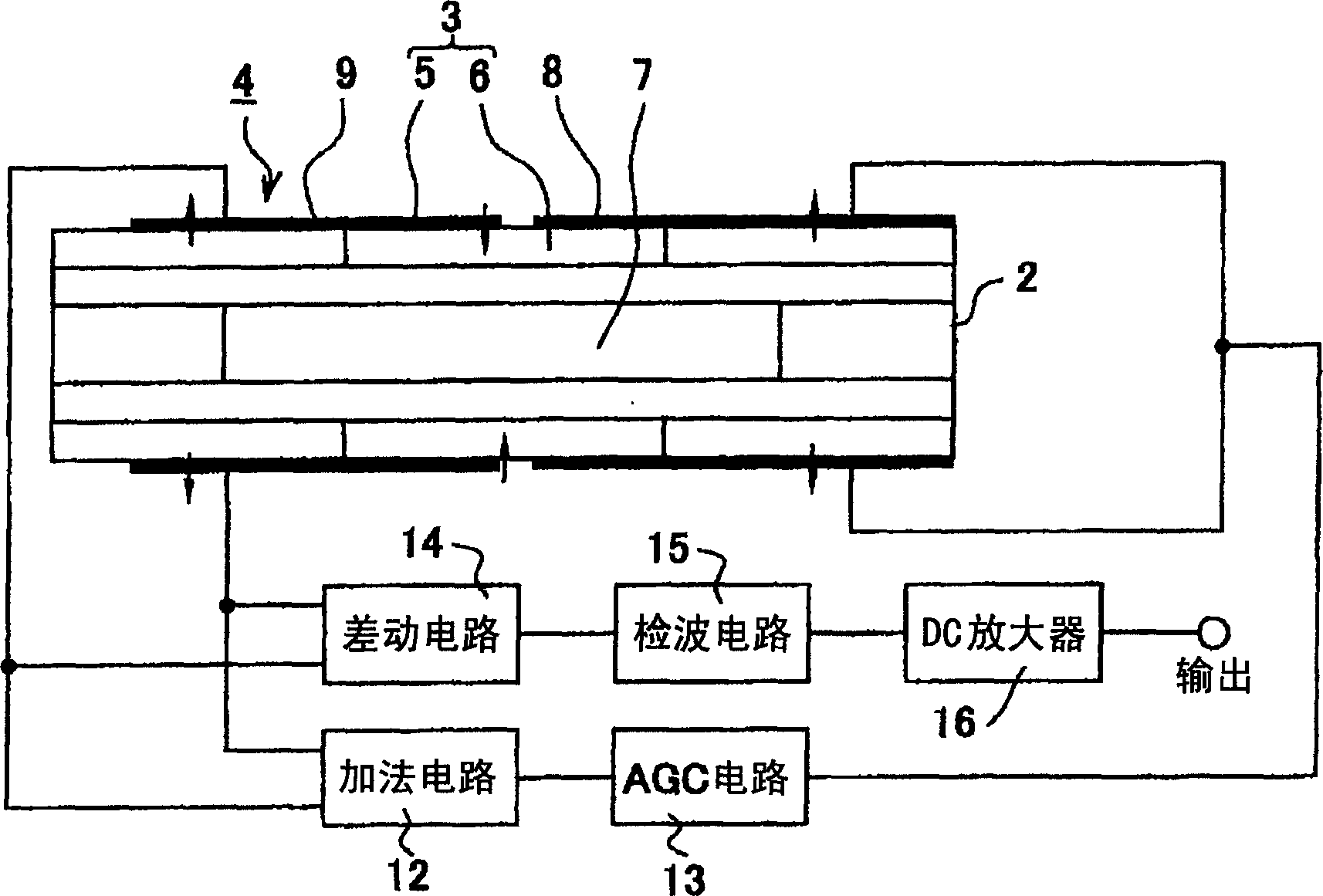

[0035] figure 1 is a perspective view of the entire structure of the vibrating gyroscope according to the first preferred embodiment of the present invention, figure 2 is a perspective view of the entire structure of the vibrator equipped with the vibrating gyroscope, image 3 is a schematic illustration of the structure of the main components of the vibratory gyroscope, including a drive detection circuit, and FIGS. 4A to 4C are top views diagrammatically showing the operation of the vibratory gyroscope, Figure 5 The relationship between the resonance frequency of buckling vibration and the resonance frequency of secondary bending vibration is shown.

[0036] also, Figures 6 to 10 The structures of the first to fourth modified examples of the vibrating gyroscope according to the first preferred embodiment are shown. also, Figure 11 The structure of the main parts of the angular velocity sensor constructed by using the vibrating gyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com