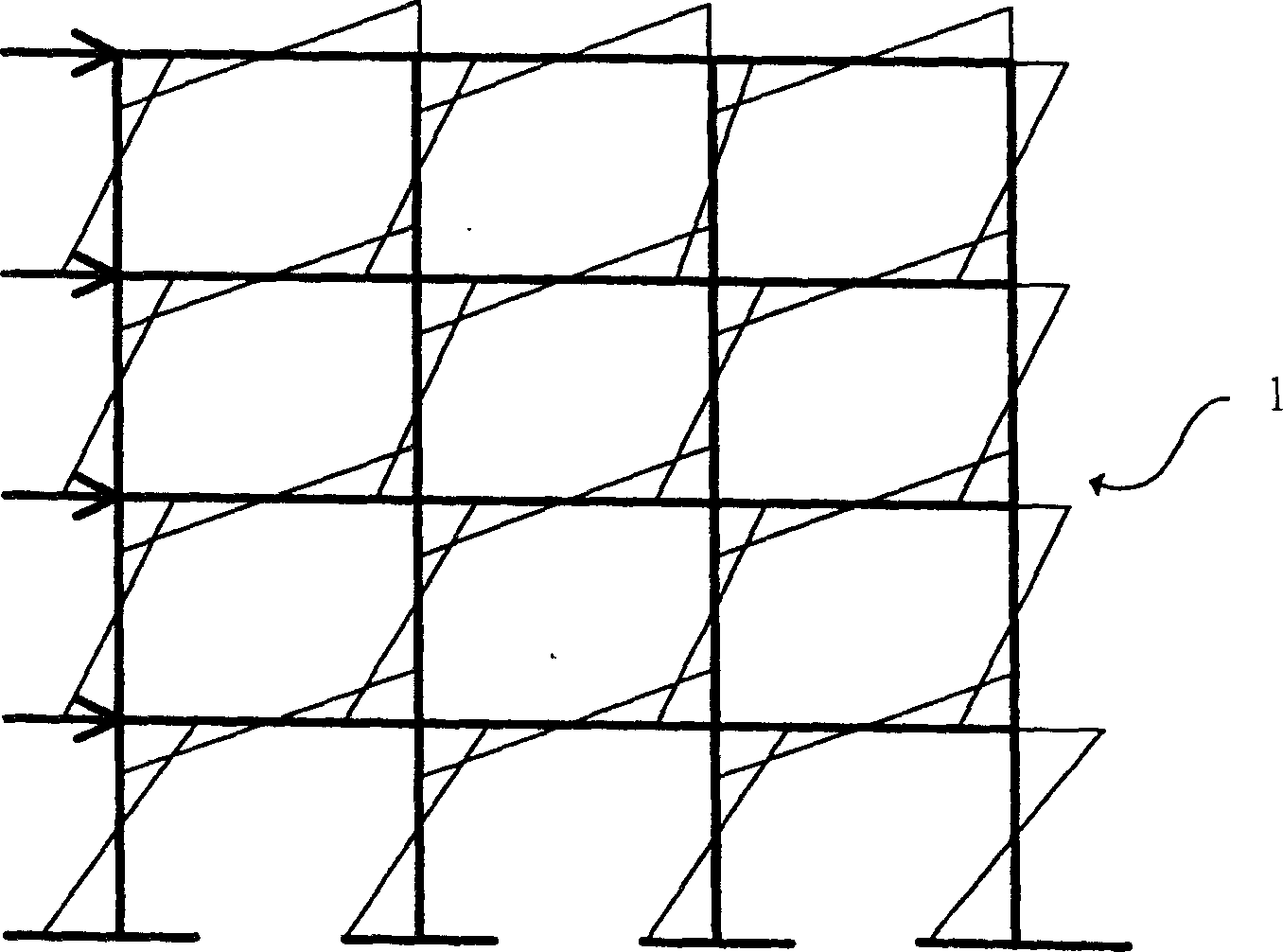

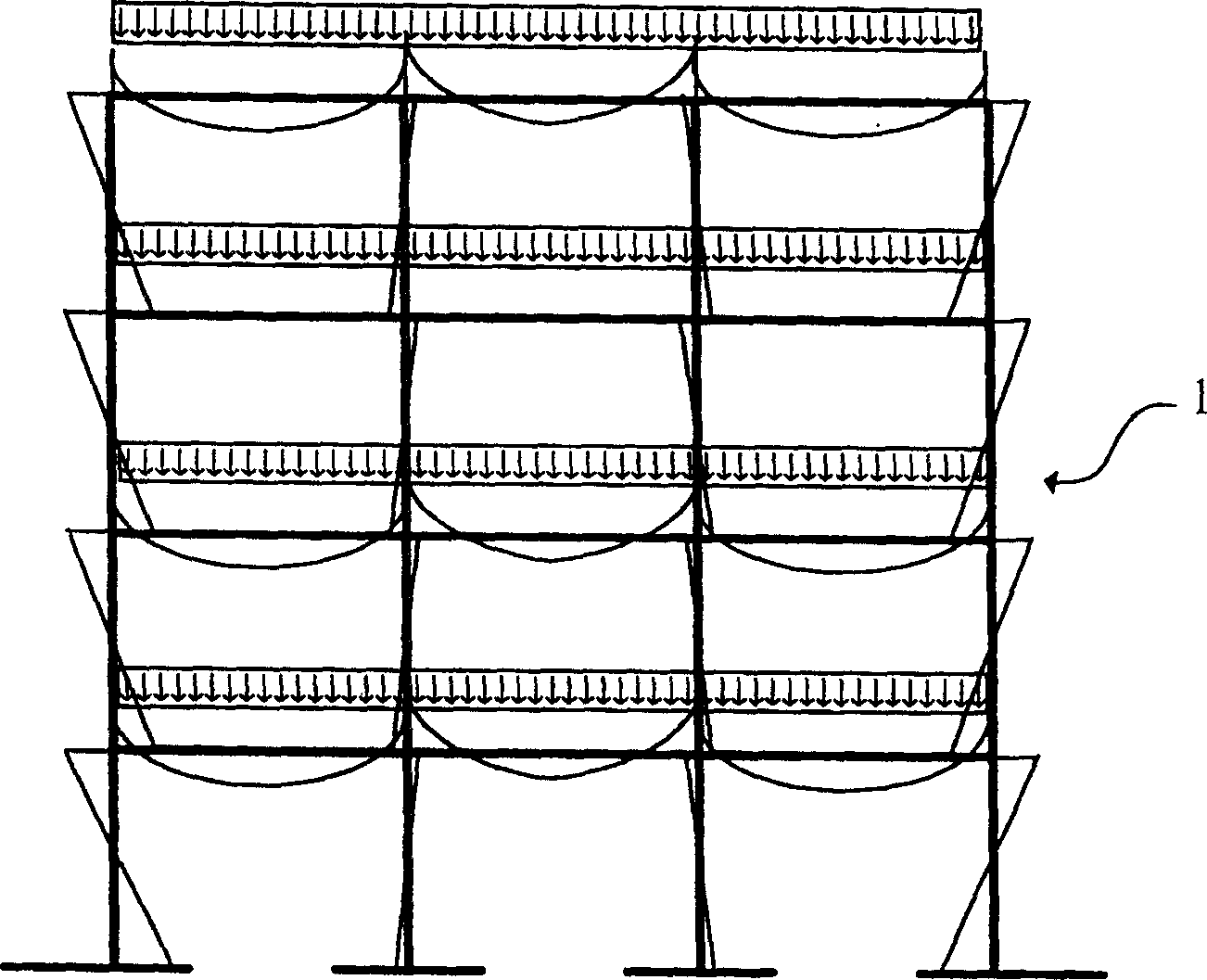

Anti bending moment structure having brace member and method thereof

A technology of supporting rods and bending moments, which is applied in the direction of building construction and construction, and can solve problems such as increased structural costs, enlarged rod sections, and increased structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

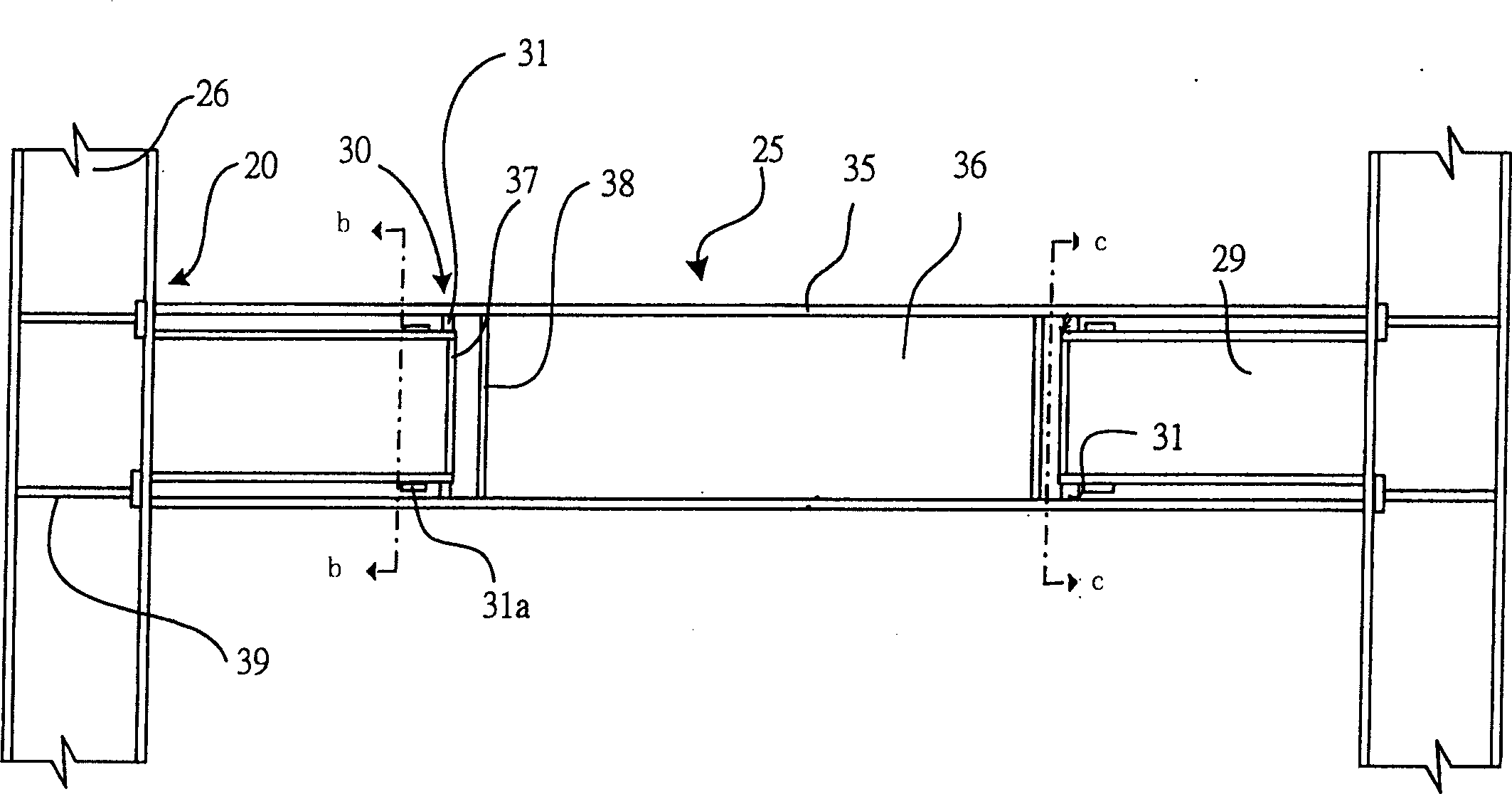

[0064] The present invention is a structure that strengthens the framework against bending moments with supporting rods. In the embodiment of Fig. 2, Fig. 2 (a) shows that the two ends of the H-shaped beam are supported by a pair of channel steel support rods 29 in the space on both sides of the web 36 between the upper and lower wings 35. Between the supported rod 25 and the supporting rod 29, a steel spacer 31 is used to transmit force at the support 30. The spacer 31 is welded to one of the supported rod 25 or the supporting rod 29, and not connected to the other rod. The reinforcing iron pieces 37 and 38 reinforce the supporting rod 29 and the supported rod 25 at the supporting position 30, and the reinforcing iron piece 39 reinforces the H-shaped steel column connection structure 26 at the bending moment joint position, so as to Transfer force to avoid local deformation caused by concentrated stress. Fig. 2 (b) is the sectional view of the b-b section in Fig. 2 (a), sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com