Method for preparing sprouting unpolished rice and sprouting unplished rice made by same

A technology for germinating brown rice and brown rice, applied in food preparation, food preservation, food science and other directions, can solve the problems of long germination process, inconvenient cooking, rough taste and odor of brown rice, etc., and achieve the effect of high safety and excellent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

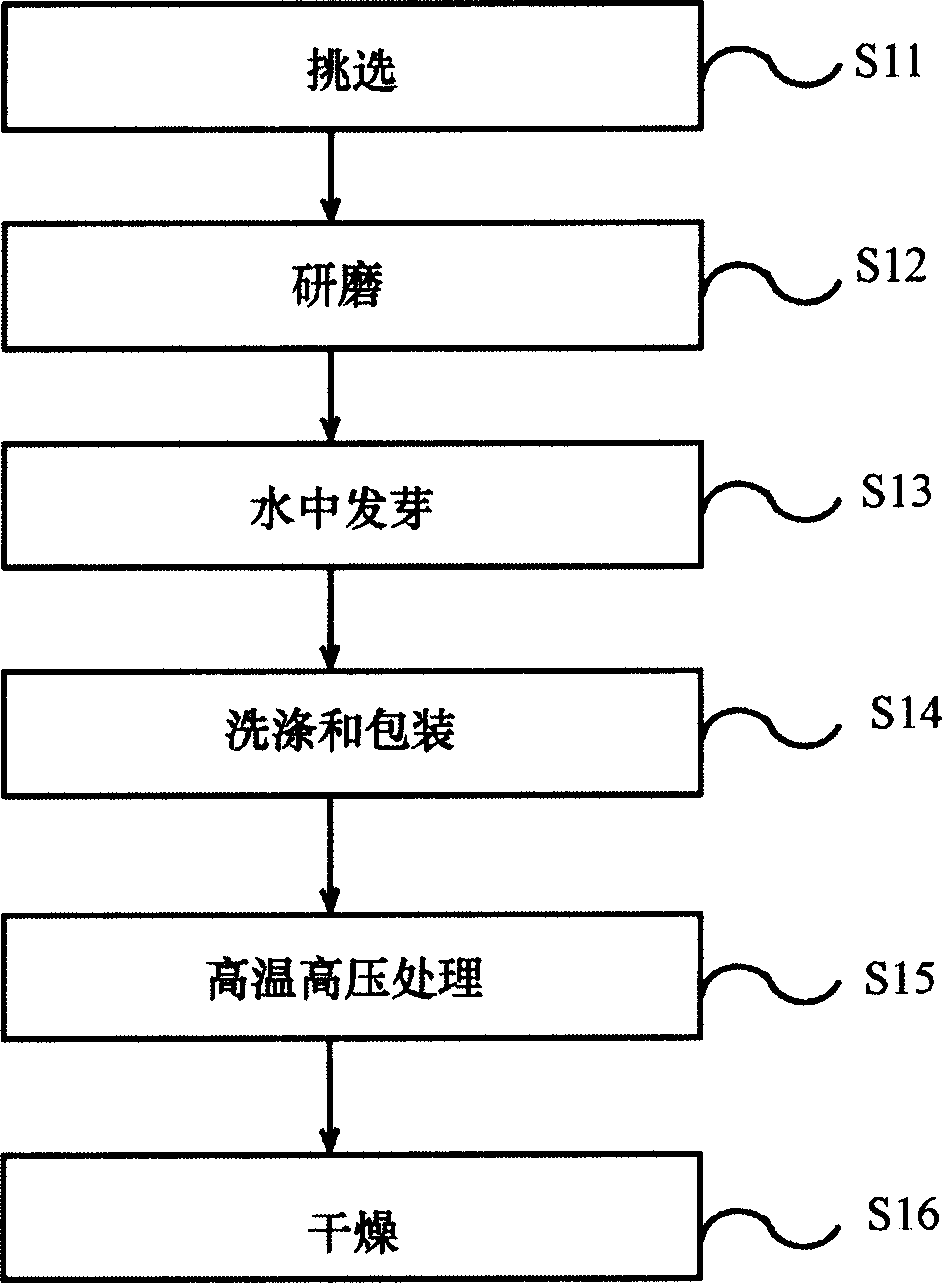

Method used

Image

Examples

Embodiment 1

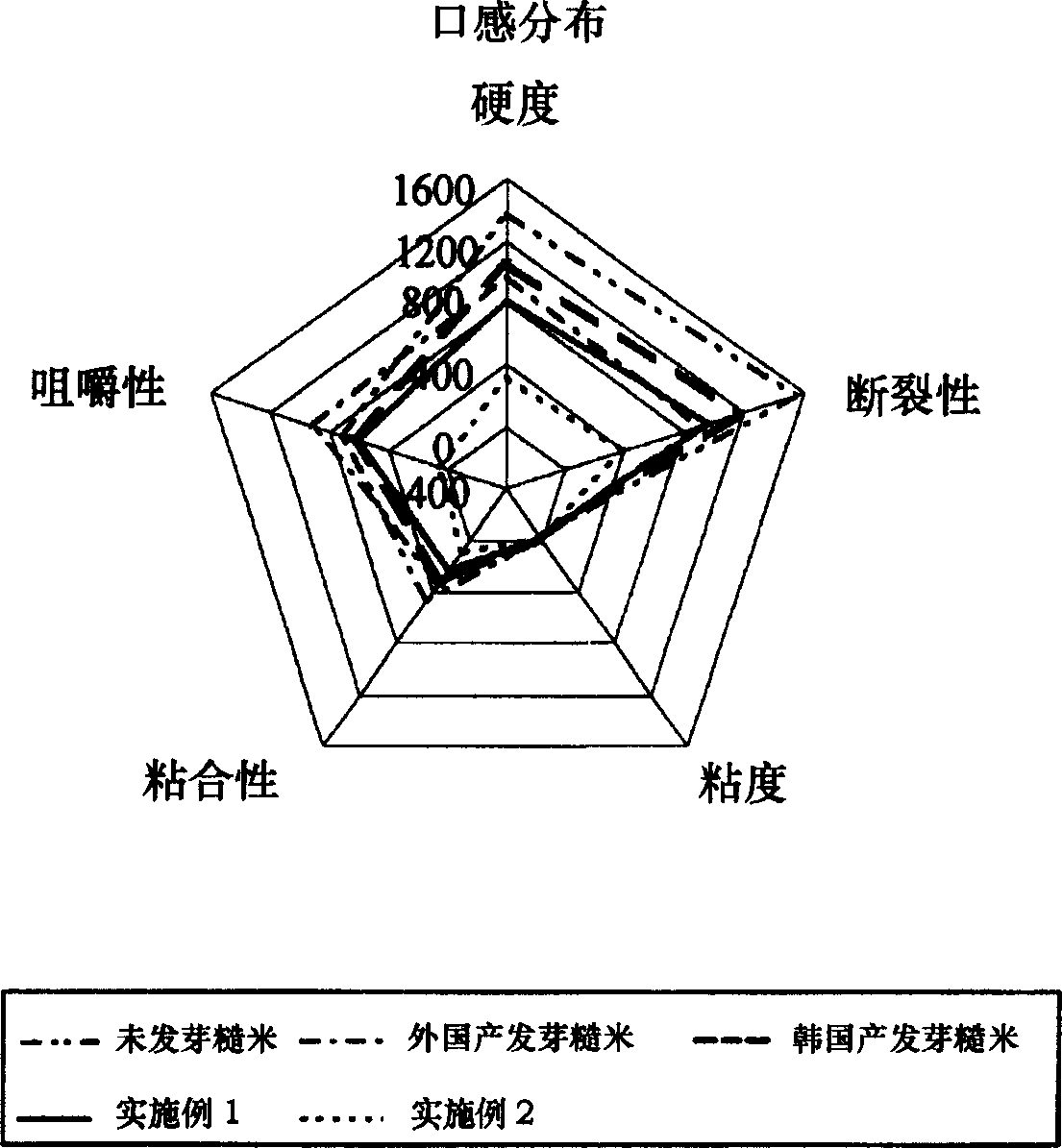

[0042] The non-waxy brown rice was ground to a level of 98.8% by weight based on the weight of the rough rice, and then the brown rice was soaked in a germination tank filled with 40° C. pH 6 germination water. After soaking, air was injected through the air injection pipe installed in the lower part of the germination tank while the brown rice was germinated for 20 hours and the germination water was replaced twice at intervals of 7 hours. The germinated brown rice obtained from the germination step was washed with clean water, sealed and packaged, and then the brown rice was autoclaved at a temperature of 121° C. by injecting steam into the jacket of the pressure cooker for 20 minutes. Thereafter the brown rice is quickly cooled with cold water. The germinated brown rice obtained from the high temperature and high pressure treatment step was then dried to a final moisture content of 15% by weight using hot air at 60°C.

Embodiment 2

[0044] The non-waxy brown rice was ground to a level of 98.8% by weight based on the weight of the rough rice, and then the brown rice was soaked in a germination tank filled with 40° C. pH 6 germination water. After soaking, air was injected through the air injection pipe installed in the lower part of the germination tank, while the brown rice was germinated for 20 hours and the germination water was replaced twice at an interval of 8 hours. The germinated brown rice obtained from the germination step was washed with clean water, sealed and packaged, and then the brown rice was autoclaved at a temperature of 121° C. by injecting steam into the jacket of the pressure cooker for 20 minutes. The brown rice was then rapidly cooled with cold water to obtain germinated brown rice having a moisture content of 34% by weight.

Embodiment 3

[0046] The non-waxy brown rice was ground to a level of 97.6% by weight based on the weight of the rough rice, and then the brown rice was soaked in a germination tank filled with 40° C. pH 6 germination water. After soaking, air was injected through the air injection pipe installed in the lower part of the germination tank, while the brown rice was germinated for 20 hours and the germination water was replaced twice at an interval of 8 hours. The germinated brown rice obtained from the germination step was washed with clean water, sealed and packaged, and then the brown rice was autoclaved at a temperature of 121° C. by injecting steam into the jacket of the pressure cooker for 20 minutes. Thereafter the brown rice is quickly cooled with cold water. Subsequently, the germinated brown rice obtained from the high temperature and high pressure treatment step was dried to a final moisture content of 15% by weight using hot air at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com