Modular air vortex spinning machine

A technology of air spinning and spinning machines, which is applied to spinning machines, free-end spinning machines, and continuous winding spinning machines, etc. It can solve the problems of spinning station stop running and reduce downtime , flexible production, less downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

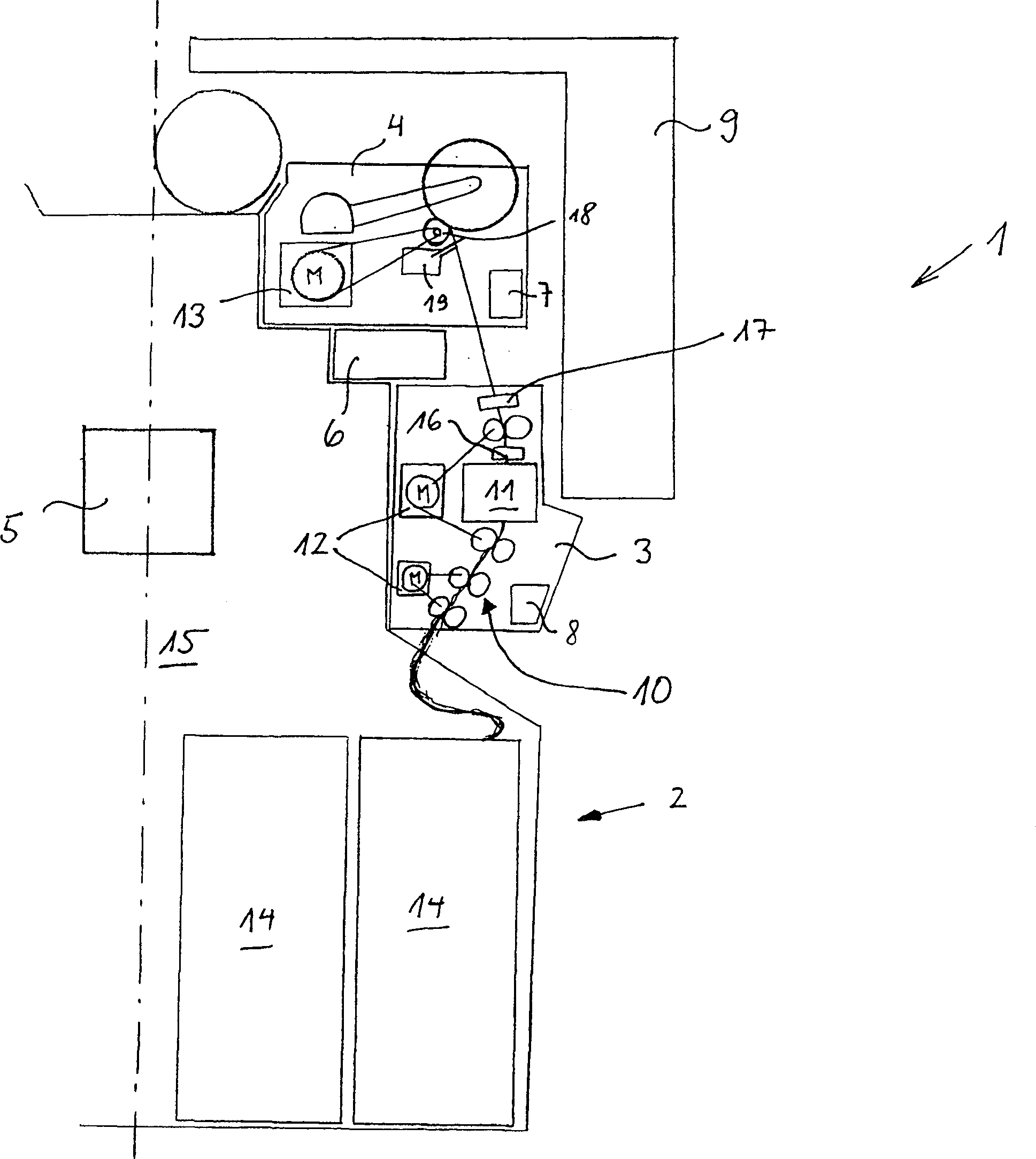

[0011] The spinning machine 1 is double-sided, whereas the figure shows only one side of the spinning machine (the dotted line indicates the mirror-reversed axis of the spinning machine 1). Of course, it is also conceivable that the spinning machine 1 shown in the figures is only designed as one-sided. The spinning station of the spinning machine 1 includes a can feed 2 . Its can feeding device 2 can occupy one or two cans 14, as shown in the figure. It is therefore irrelevant for the invention whether one or more cans 14 are provided and whether the can feeding device 2 is arranged in the spinning station or adjacent to or in front of it. It is also conceivable that one can feed device 2 feeds several spinning units 3, and / or several spinning stations roving. This just means that the present invention covers this kind of possibility, promptly can feed device 2 supplies several spinning stations (for example two) fiber material.

[0012] Generally, however, for a spinning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com