Rotary brush device and dust cleaner using same

A technology of rotating brushes and vacuum cleaners, applied in the directions of vacuum cleaners, suction nozzles, applications, etc., can solve the problems that the rotating force mechanism occupies a large space, restricts the miniaturization of equipment, and is not ideal for use and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

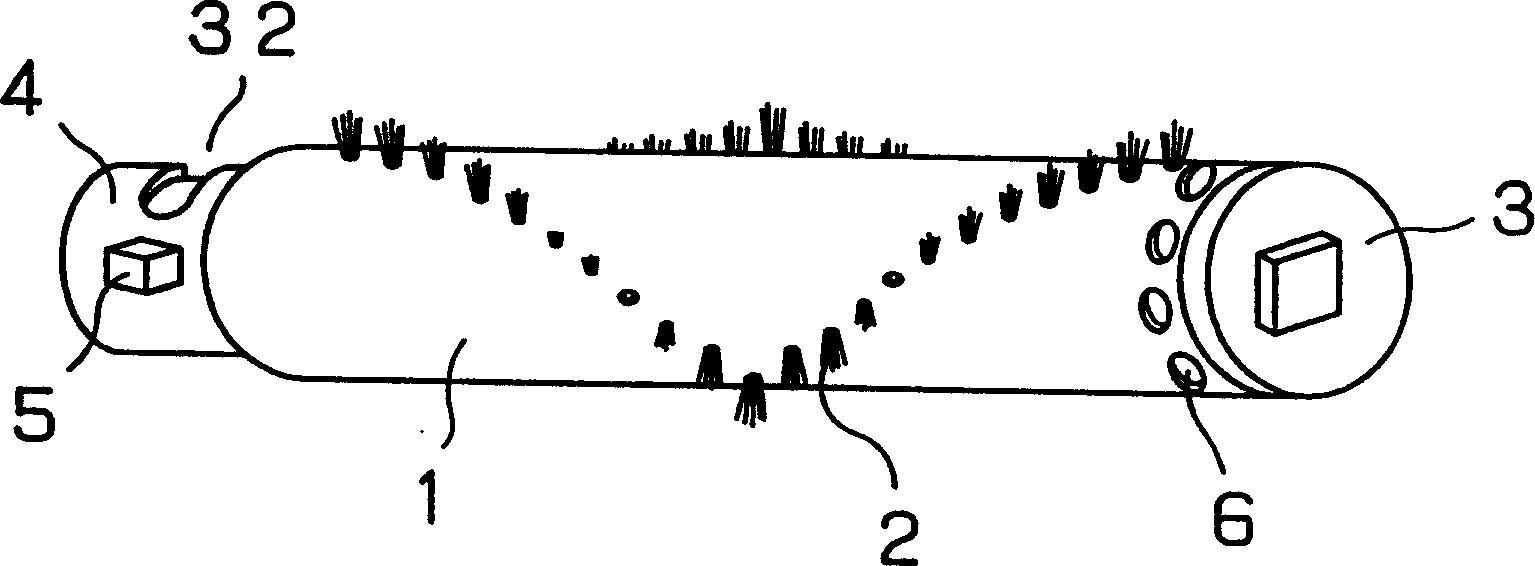

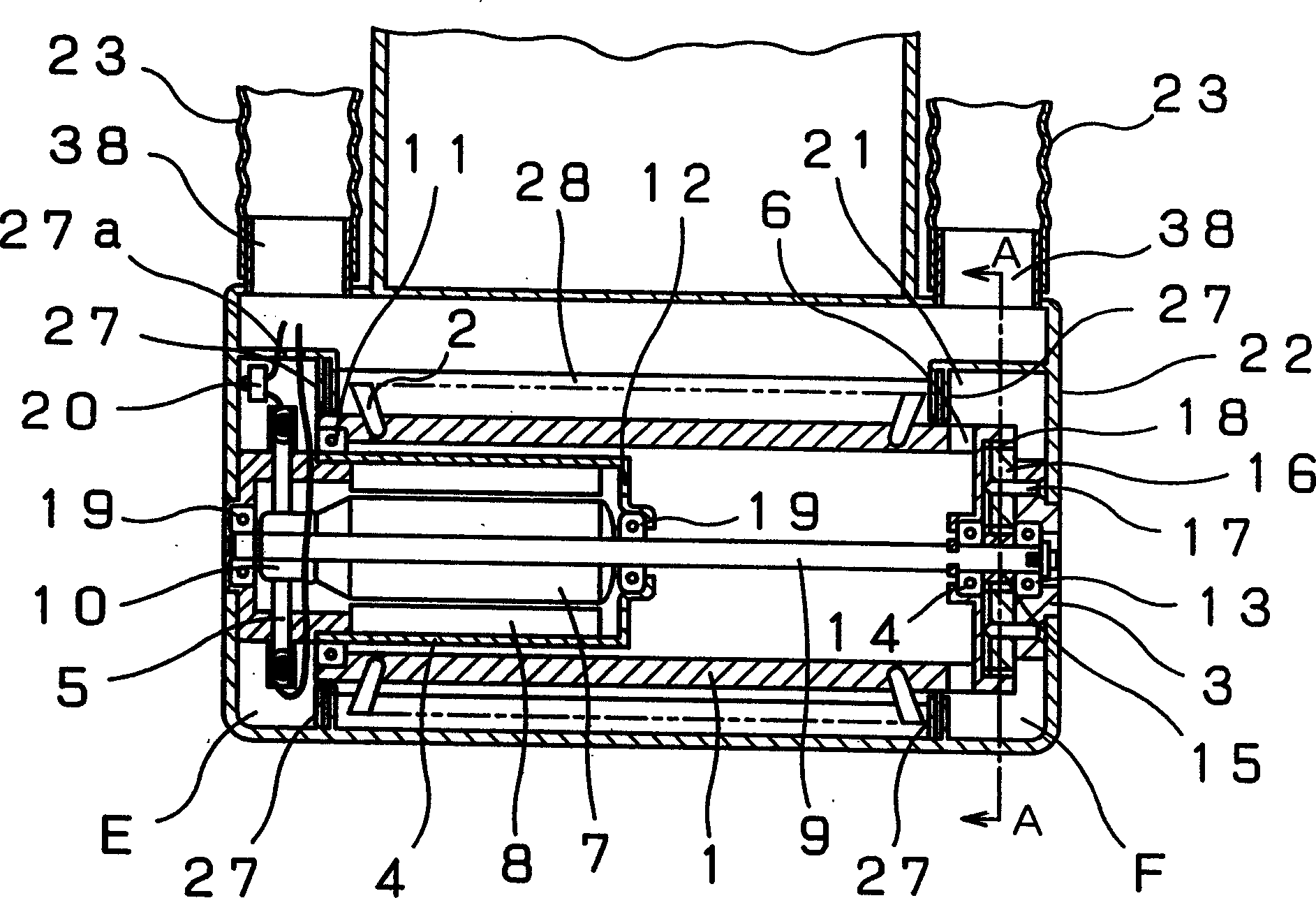

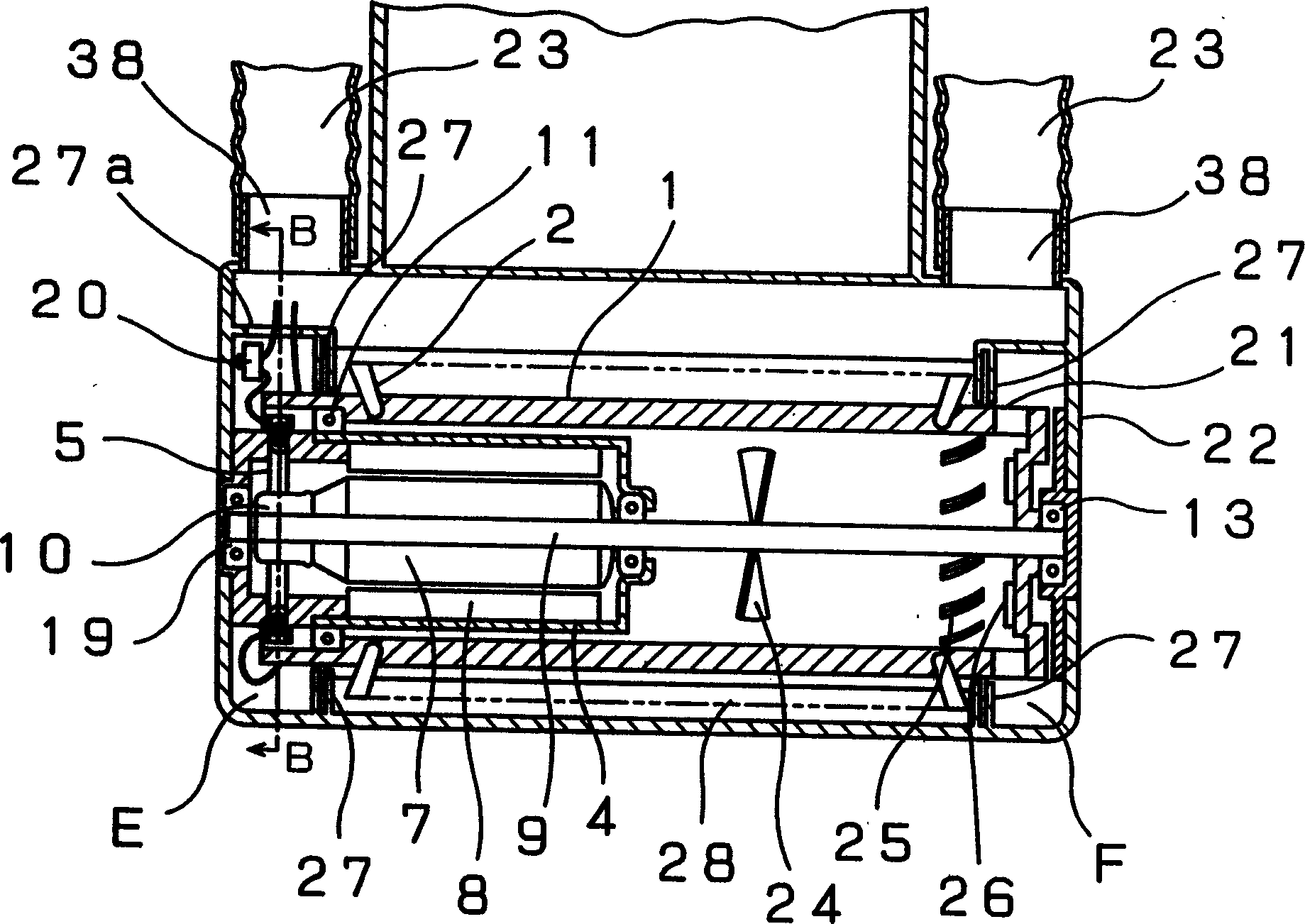

[0025] Embodiments of the present invention will be described below using the drawings. figure 1 Among them, 1 is a cylindrical body, and 2 is a brush in which bristles are planted in a V shape on the outer peripheral surface of the cylindrical body 1, and these two constitute a rotating brush. In addition, depending on the purpose and use, instead of a brush shape, a thin plate-shaped stirring material, a wiper, or the like may be used. In addition, a rotating brush can also be formed by appropriately combining a brush-shaped stirring member, a thin-plate-shaped stirring member, and a wiping member. 3 is a reduction gear frame constituting a reduction mechanism, 4 is a motor frame supporting a motor installed in the cylindrical body 1, 5 is a carbon brush, and 6 is a first opening, which is provided on the outer periphery of the cylindrical body 1 for ventilation. through hole. The first opening 6 is formed on the end peripheral surface of the cylindrical body 1, and is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com