Acrylic acid series resin particle, coating combination and optical material

An acrylic resin and optical material technology, applied in the direction of coating, etc., can solve problems such as uneven light diffusion, and achieve the effect of improving surface smoothness and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

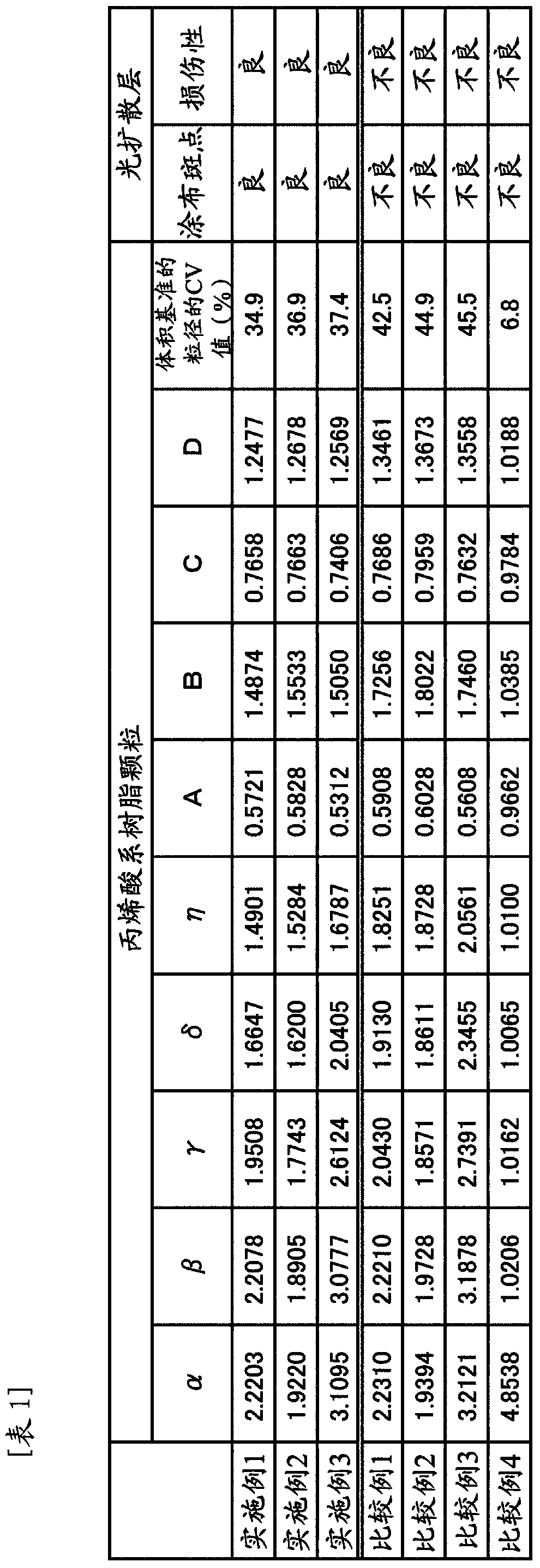

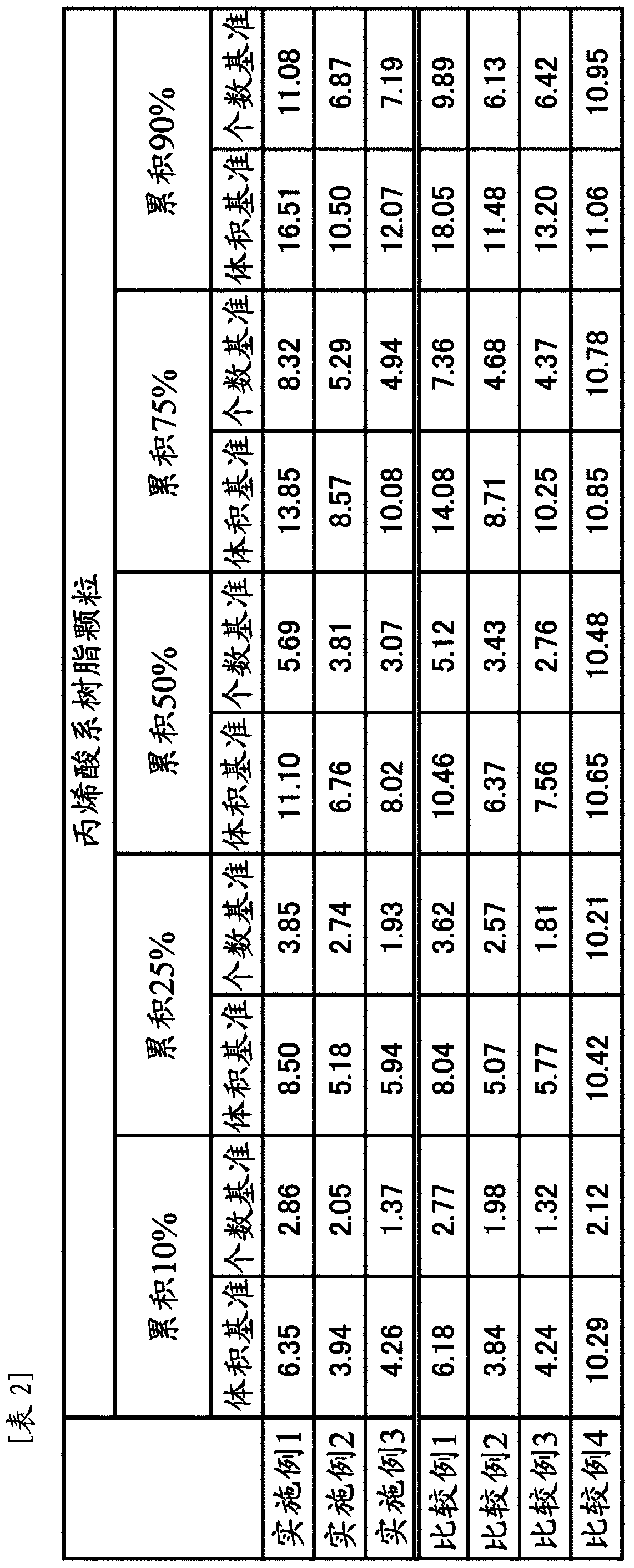

Embodiment 1)

[0089] A monomer composition containing 95 parts by weight of methyl methacrylate, 5 parts by weight of ethylene glycol dimethacrylate, and 0.4 parts by weight of benzoyl peroxide, and 200 parts by weight of deionized water were used as the acid-soluble insoluble monomer composition. 6 parts by weight of calcium triphosphate as a dispersion stabilizer composed of a water-soluble inorganic compound, and 0.1 part by weight of sodium lauryl sulfate were supplied to a mixer (trade name "TK ホモミキサー" manufactured by Special Machinery Co., Ltd.), and mixed at 4500 rpm for 10 minutes to obtain a dispersion in which the monomer composition is uniformly dispersed in deionized water.

[0090] The dispersion liquid was supplied into the polymerization reactor, and the monomer composition was subjected to suspension polymerization at 70° C. for 3 hours while stirring to obtain a suspension in which cross-linked polymethyl methacrylate particles were dispersed in water.

[0091] After adding...

Embodiment 2)

[0094] The cross-linked polymethyl methacrylate particles before classification were obtained in the same manner as in Example 1, except that the number of revolutions of the mixer was 7000 rpm.

[0095] Next, the obtained cross-linked polymethyl methacrylate particles were put into a turbo classifier (trade name "Type TC-15" manufactured by Nissin Engineering Co., Ltd.) for classification, and the cross-linked polymethyl methacrylate having a particle size of 15 μm or more was removed. Ester particles and cross-linked polymethyl methacrylate particles having a particle diameter of 1 to 4 μm were obtained to obtain classified cross-linked polymethyl methacrylate particles.

Embodiment 3)

[0097] In place of methyl methacrylate and ethylene glycol dimethacrylate, 35 parts by weight of butyl methacrylate, 35 parts by weight of butyl acrylate and 30 parts by weight of ethylene glycol dimethacrylate were used in the mixer. Except that the number of revolutions was 6500 rpm, the same method as in Example 1 was used to obtain crosslinked acrylic resin particles before classification.

[0098] Next, the obtained cross-linked acrylic resin particles were put into a turbo classifier (trade name "Type TC-15" manufactured by Nisshin Engineering Co., Ltd.) and classified to remove cross-linked polymethyl methacrylate particles having a particle size of 15 μm or more and The crosslinked acrylic resin particles having a particle diameter of 1 to 4 μm were obtained as classified crosslinked acrylic resin particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com