Plate type apparatus for producing fresh water

A plate type and end plate technology, applied in water/sewage treatment, fixed plate conduit assembly, heating water/sewage treatment, etc., can solve problems such as large heat transfer area, large heat transfer plate, and insufficient heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

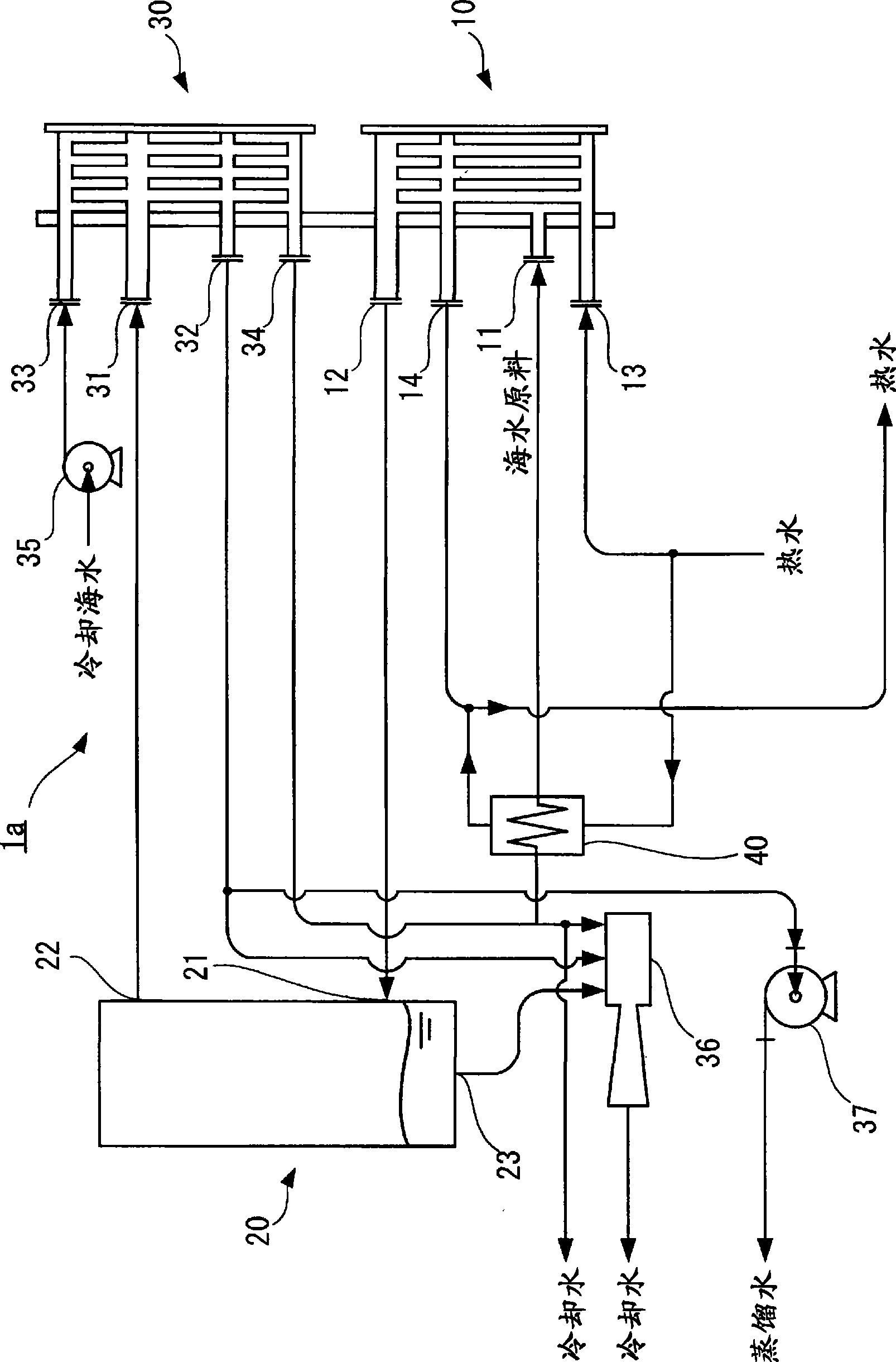

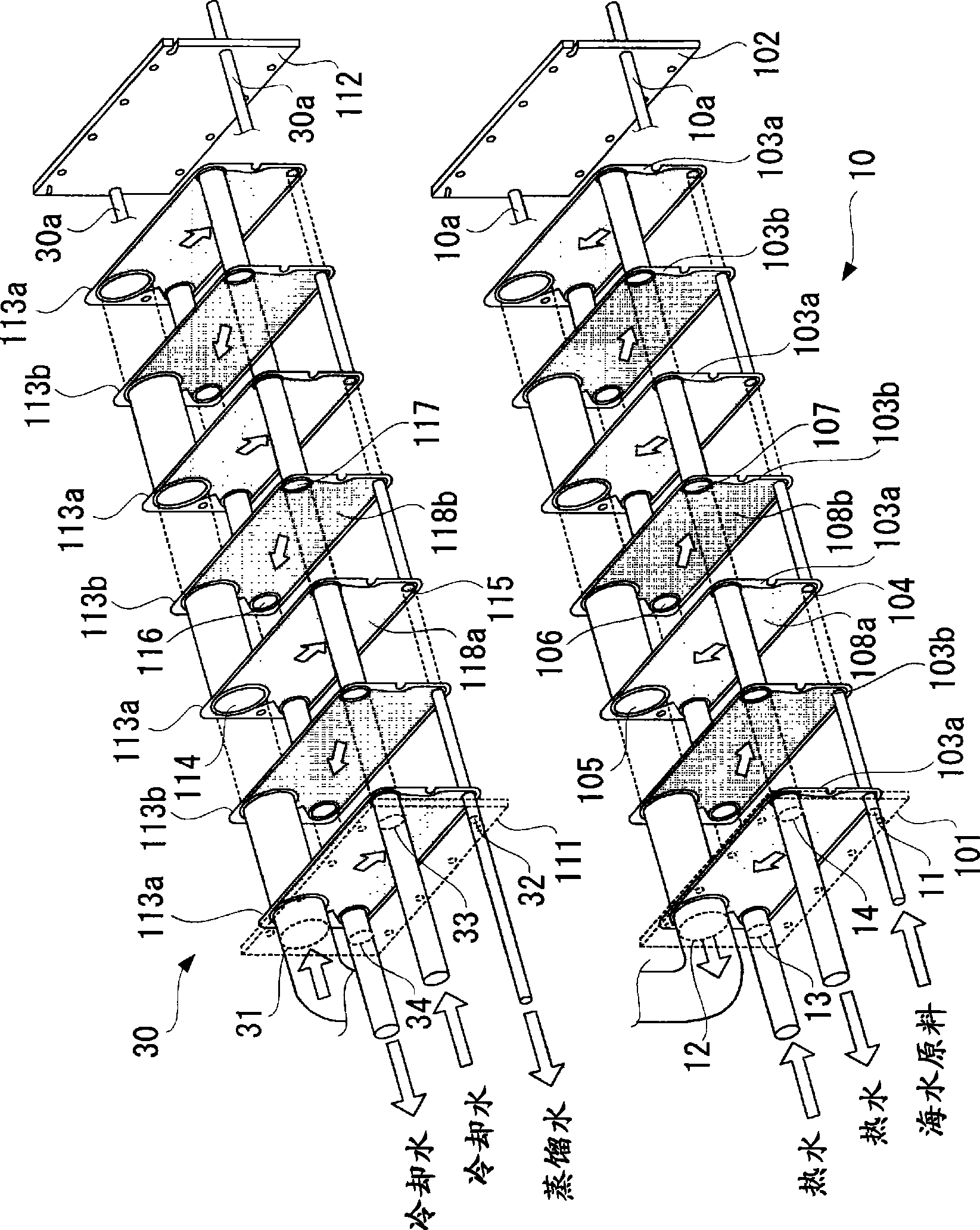

[0032] figure 1 It is a schematic configuration diagram of the plate type water generating device according to the first embodiment of the present invention. Such as figure 1 The plate type water generating device 1a shown above is equipped with: a heater 10 for heating seawater raw materials to generate water vapor; an evaporator 20 for separating water vapor and brine (concentrated seawater); and a condenser 30 for cooling water vapor to generate distilled water, which is particularly suitable for making Water making device for ships.

[0033] The heater 10 is provided with: a raw material water inlet 11 and a steam and brine outlet 12 for respectively introducing and discharging seawater; a hot water inlet 13 and a hot water outlet for respectively introducing and discharging hot water such as jacket cooling water of a ship engine The seawater raw material introduced from the raw water inlet 11 is heated and evaporated by the hot water introduced from the hot water inle...

no. 2 Embodiment approach

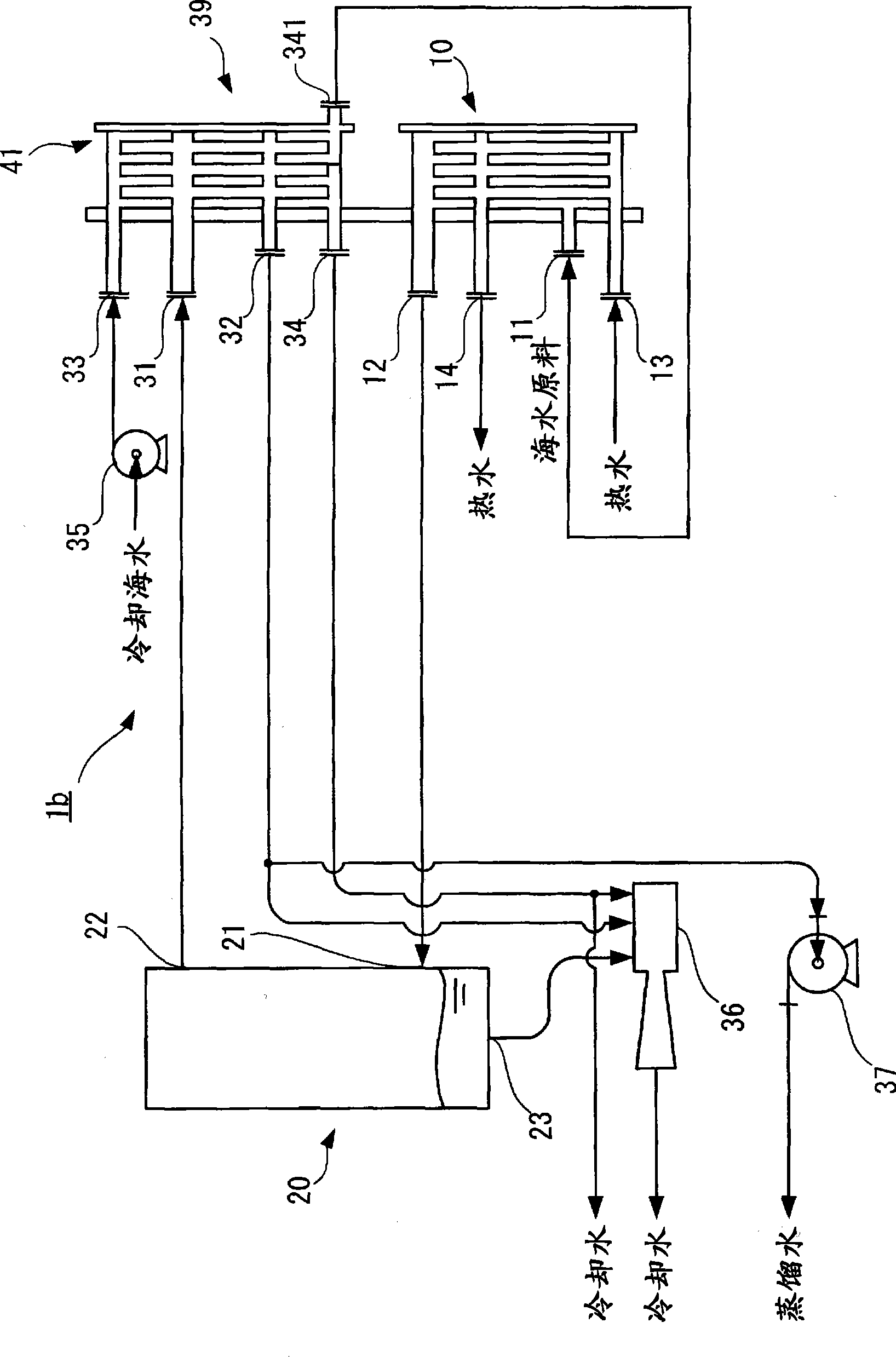

[0049] image 3 It is a schematic configuration diagram of a plate-type water-making device according to a second embodiment of the present invention, Figure 4 It is a perspective view of the main part of the condenser. The plate type water generation device 1b of the present embodiment has a structure in which the condenser 30 is provided with a seawater raw material preheating unit instead of the heat exchanger 40 provided in the plate type water generation device 1a of the first embodiment. image 3 and Figure 4 in, right and figure 1 and figure 2 Components that are the same as those in the first embodiment shown are denoted by the same reference numerals, and description thereof will be omitted.

[0050] Such as Figure 4 As shown, the condenser 39 of this embodiment is equipped with the partition plate 39a between two adjacent heat transfer plates 113a, 113b. The partition plate 39a has the distillation flow ports 114, 115 and the cooling water flow port 116 si...

no. 3 Embodiment approach

[0059] Figure 5 is a schematic configuration diagram of a plate-type water-making device according to a third embodiment of the present invention, Figure 6 It is a perspective view of the main part of the heater. The plate type water generation device 1c of the present embodiment has a structure in which a heater 10 is provided with a seawater raw material preheating unit instead of the heat exchanger 40 provided in the plate type water generation device 1a of the first embodiment. Figure 5 and Figure 6 in, right and figure 1 and figure 2 Components that are the same as those in the first embodiment shown are denoted by the same reference numerals, and description thereof will be omitted.

[0060] Such as Figure 6 As shown, the heater 19 of this embodiment is equipped with the partition plate 19a between two adjacent heat transfer plates 103a, 103b. The partition plate 19a has the raw material water distribution port 104 and the hot water distribution ports 106 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com