Wrapped steel wire

A steel wire rope, covering type technology, applied in the direction of transportation and packaging, transmission element or pulley rope or cable, coating, etc., can solve the problems of high price pulley, time-consuming, low position control accuracy and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

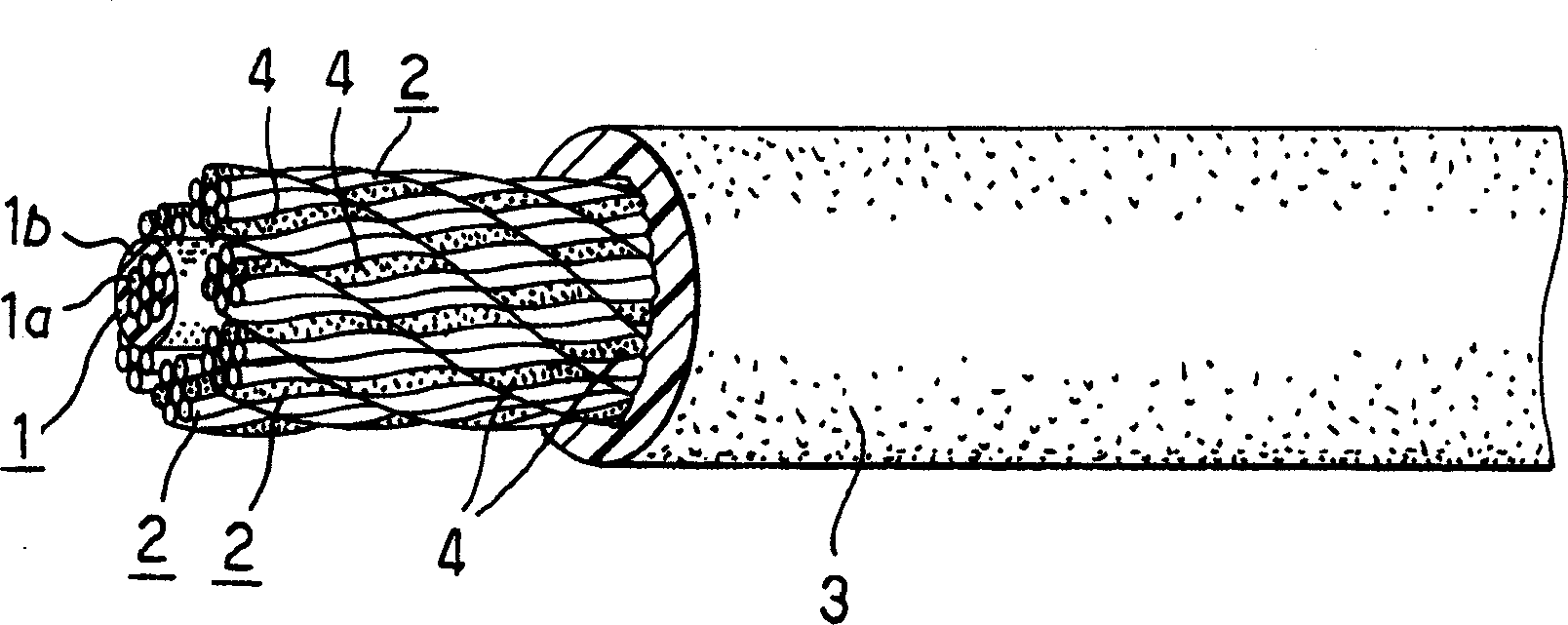

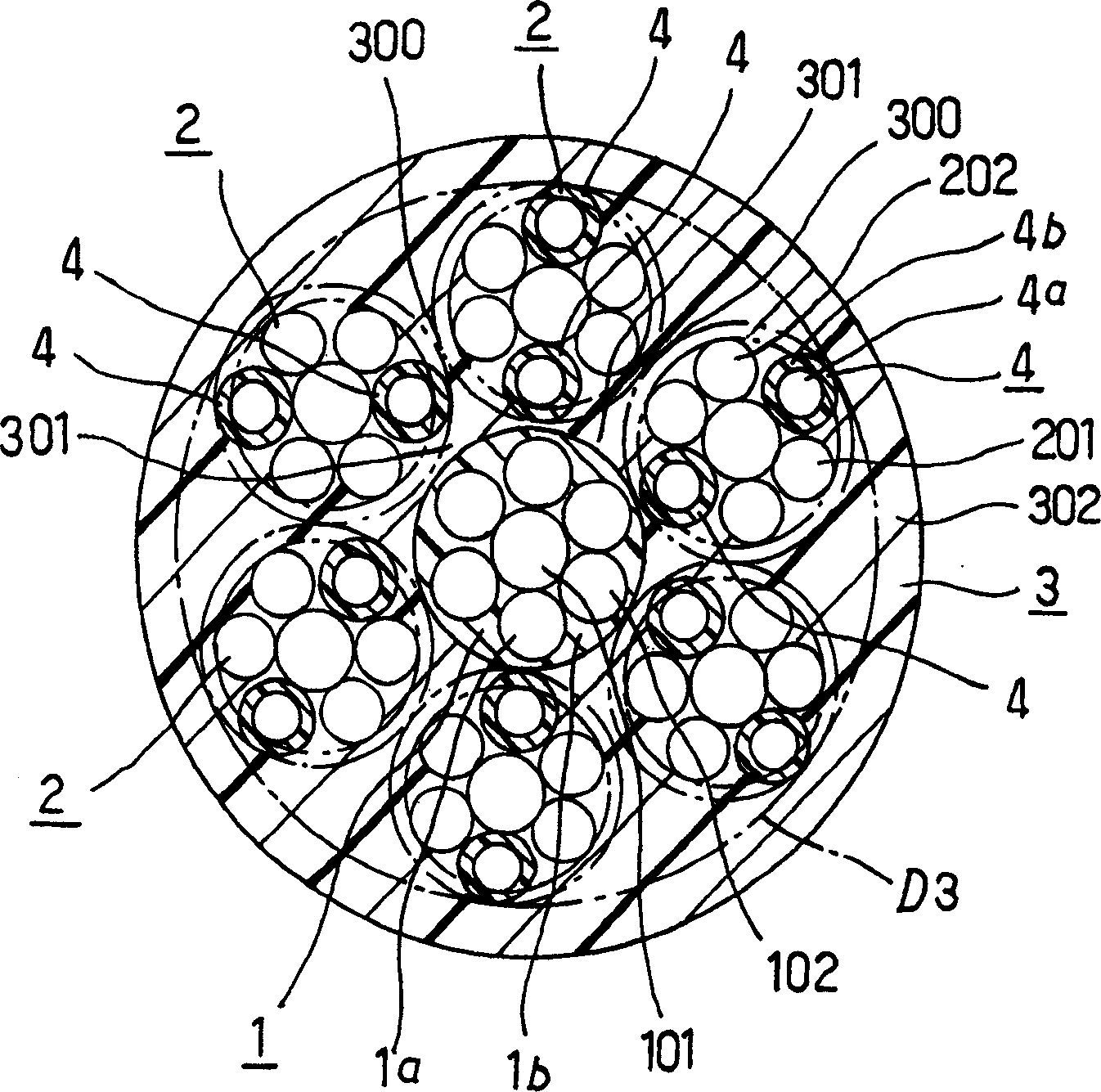

[0042] figure 1 - Figure 6 shows a first embodiment of a sheathed steel cord according to the invention.

[0043] exist figure 1 , 2 In the figure, symbol 1 denotes a rope core, and a synthetic resin coating layer 1b is formed on the outer periphery of a rope core body 1a formed by twisting a single thin steel wire or a steel strand. Although the configuration of the core body 1a may be arbitrary, in this example, it has a 1×7 structure in which six side wires 102 are arranged around a center wire 101 and twisted together.

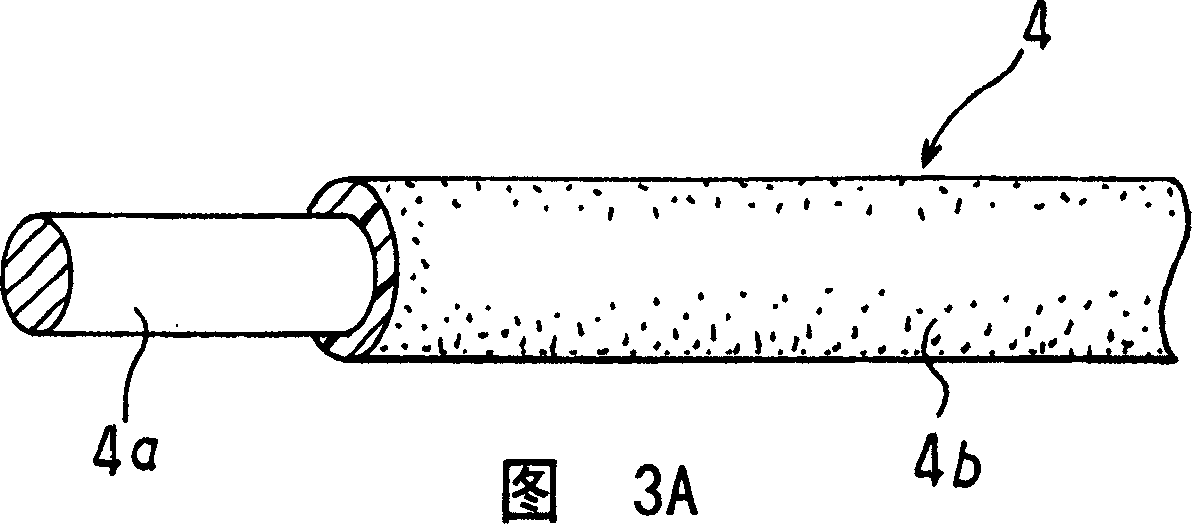

[0044]2 is a plurality of (six in the figure) side strands arranged around the core 1 and twisted. 3 is an outer covering layer (full covering) of synthetic resin applied to contain the side strands 2, which fills and blocks the gaps between the adjacent side strands 2 and 2, and the gap between each side strand 2 and the cord 1. gap.

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com