Pressure sensor for measuring hydraulic pressure

A pressure sensor, hydraulic pressure technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through mechanical components, measuring fluid pressure through electromagnetic components, etc., can solve problems such as troublesome recalibration, loss of pressure transducer, false measurement signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

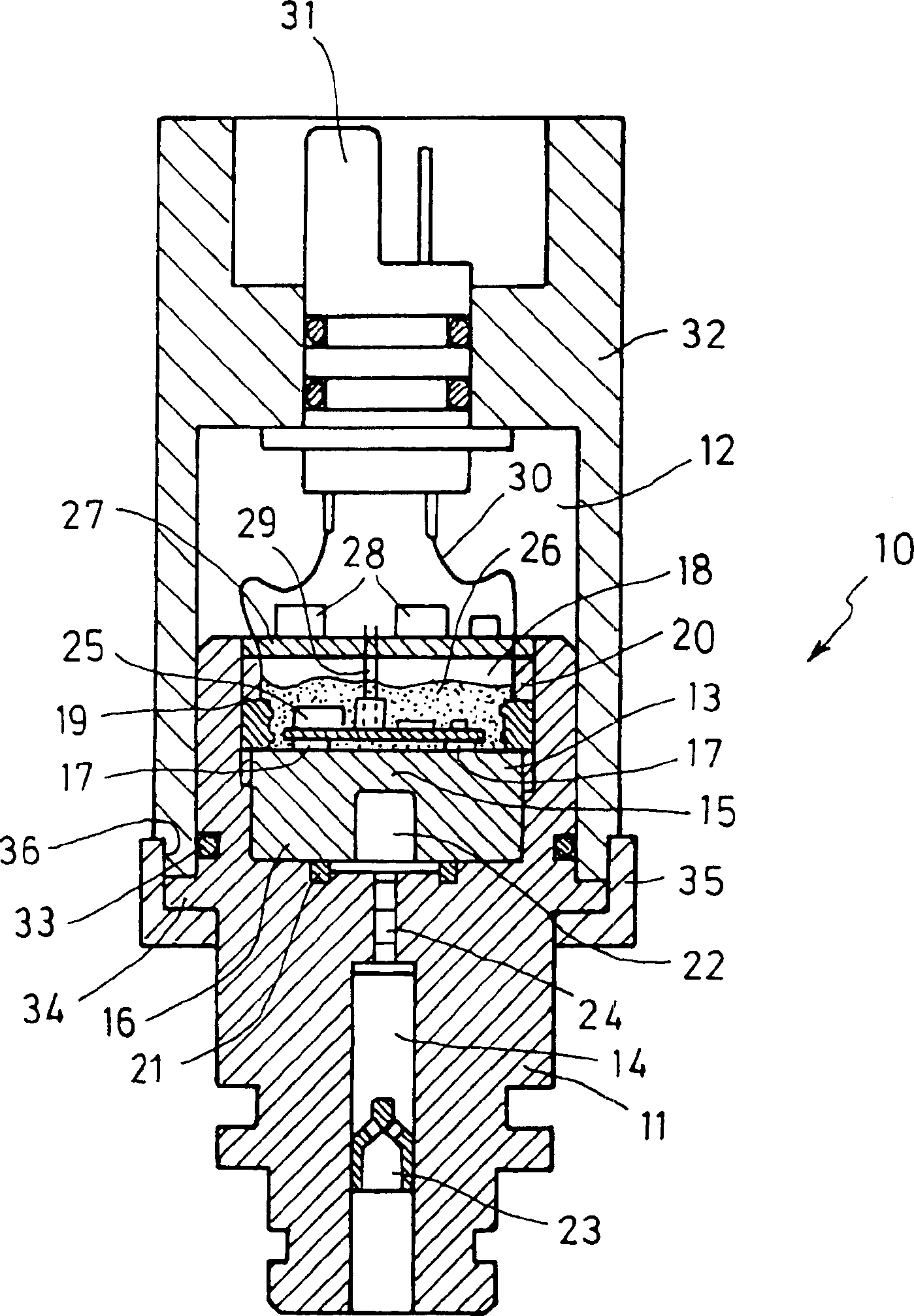

[0013] 10 in the figure represents a pressure sensor as a whole, such as for measuring the hydraulic pressure of an underground mining hydraulic system, which is within the inherently safe electric power range. The pressure sensor 10 has a connecting element 11 which can be connected to a pressure sensor connection of a liquid cylinder (not shown) or the like, and a sensor housing 12 in which a hydroelectric pressure transducer 13 is arranged. The pressure transducer is loaded with hydraulic pressure next to the pressure sensing connection via a pressure channel 14 extending through the connecting element 11 and converts the pressure value into an electrical measurement signal which can be directed to a control device, a remote measuring table or a remote display.

[0014] According to the invention, the pressure transducer 13 has a ceramic load cell 15, which essentially comprises an approximately circular ceramic body 16 with a plurality of strain gauges 17 arranged thereon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com