Leakage circuit breaker

A leakage circuit breaker and leakage circuit breaker technology, applied in circuits, electrical components, emergency power protection, etc., can solve the problem of leakage protection function not working.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

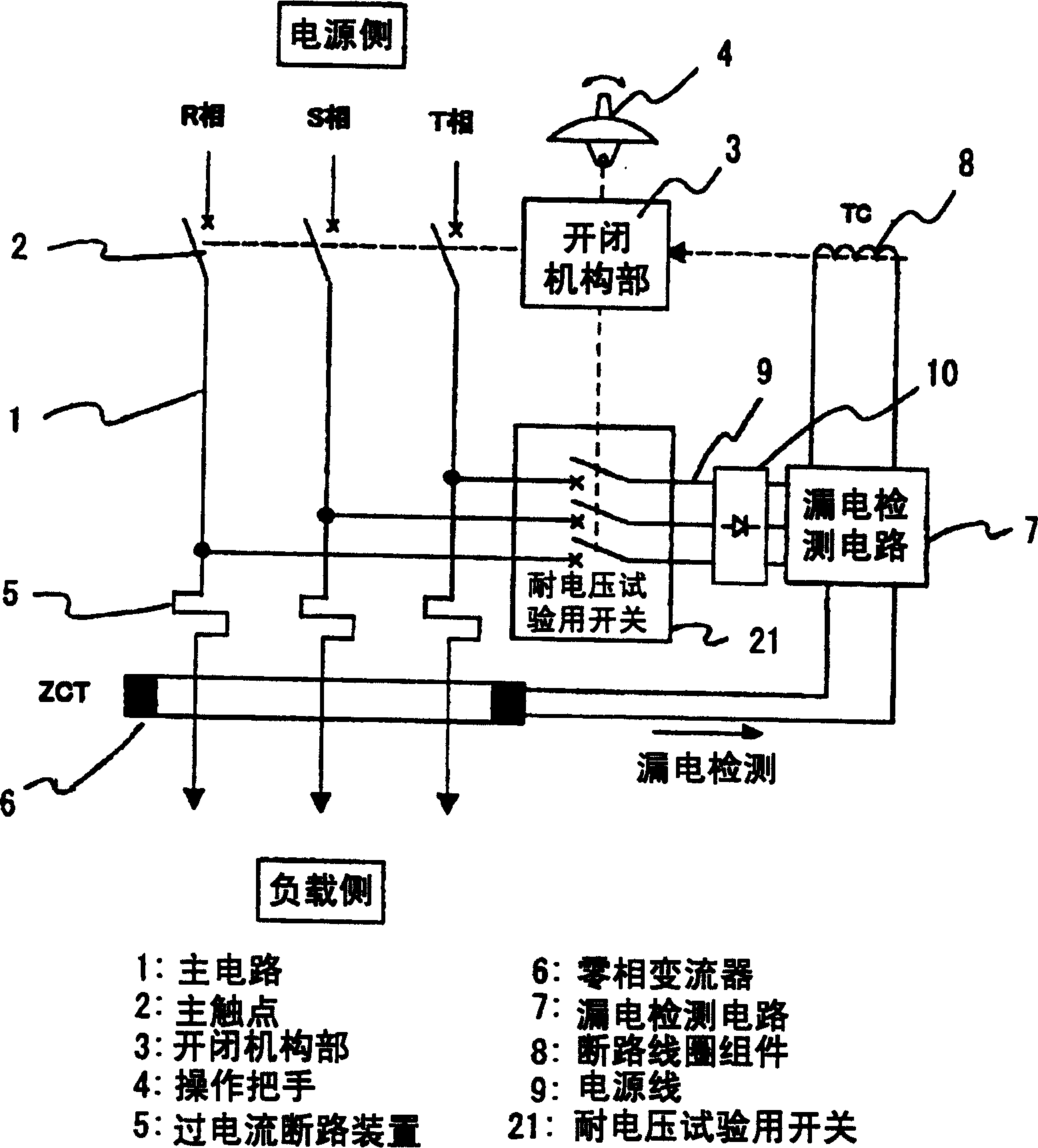

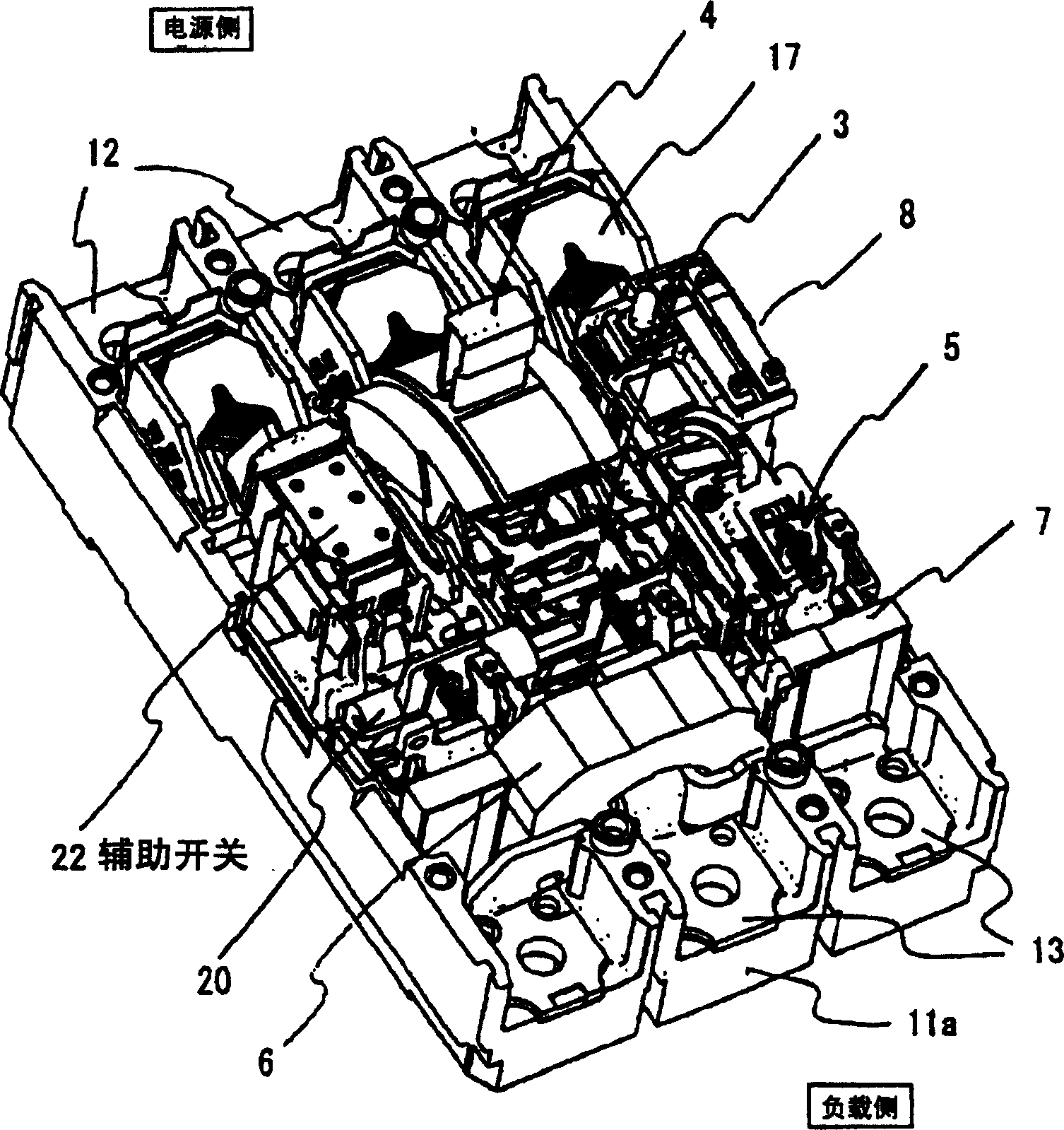

[0042] Figure 1 ~ Figure 3 It is a composition diagram of an embodiment of the present invention corresponding to the first and second inventions. The earth leakage circuit breaker of this embodiment and Figure 7 , Figure 8 The existing composition of is basically the same, but like figure 1 As shown in the circuit diagram of , for the power supply circuit of the leakage detection circuit 7 with the power line 9 laid between the main circuit 1, a switch 21 for withstand voltage testing is installed. The withstand voltage test switch 21 is a switch that operates to connect and disconnect the above-mentioned power supply circuit according to the opening and closing operation of the main contact 2. In this embodiment, as described later, it is an accessory of the leakage circuit breaker An auxiliary switch mounted on the main body case 11 is used. In addition, in the illustrated embodiment, between the main circuit 1 and the leakage detection circuit 7, three power supply ...

Embodiment 2

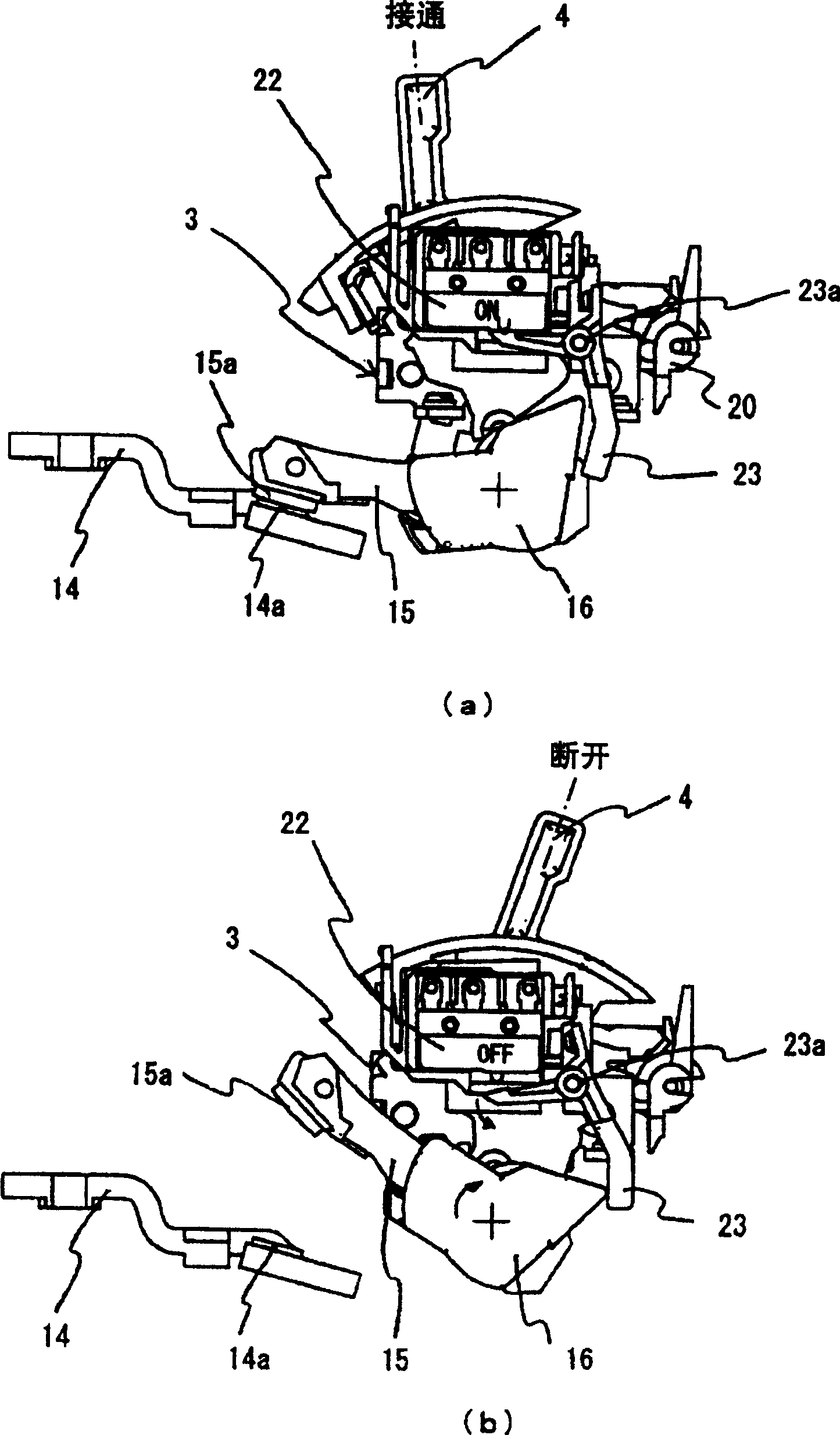

[0051] pass below Figure 4 ~ Figure 7 , the composition and operation of the embodiments corresponding to the third to fifth inventions of the present invention will be described.

[0052] This example targets figure 1 The withstand voltage test switch 21 further expands its function. That is, in this embodiment, the switch 21 for the withstand voltage test is a manually operated switch, which is connected to the disconnection bar of the switching mechanism section 3 as described later. In addition, if the switch 21 for the withstand voltage test is manually turned off when carrying out the withstand voltage test, and the power supply circuit of the power line 9 laid between the main circuit 1 and the leakage detection circuit 7 is disconnected, then Accompanying this operation, the switching mechanism section 3 is disconnected, and the main contact 1 is opened, whereby the withstand voltage test is ready. In addition, after the withstand voltage test is completed, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com