Thermal fuse

A technology for thermal fuses and metal terminals, which is applied to electrical components, electric switches, circuits, etc., and can solve problems such as poor wettability and thermal fuses that cannot be blown quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

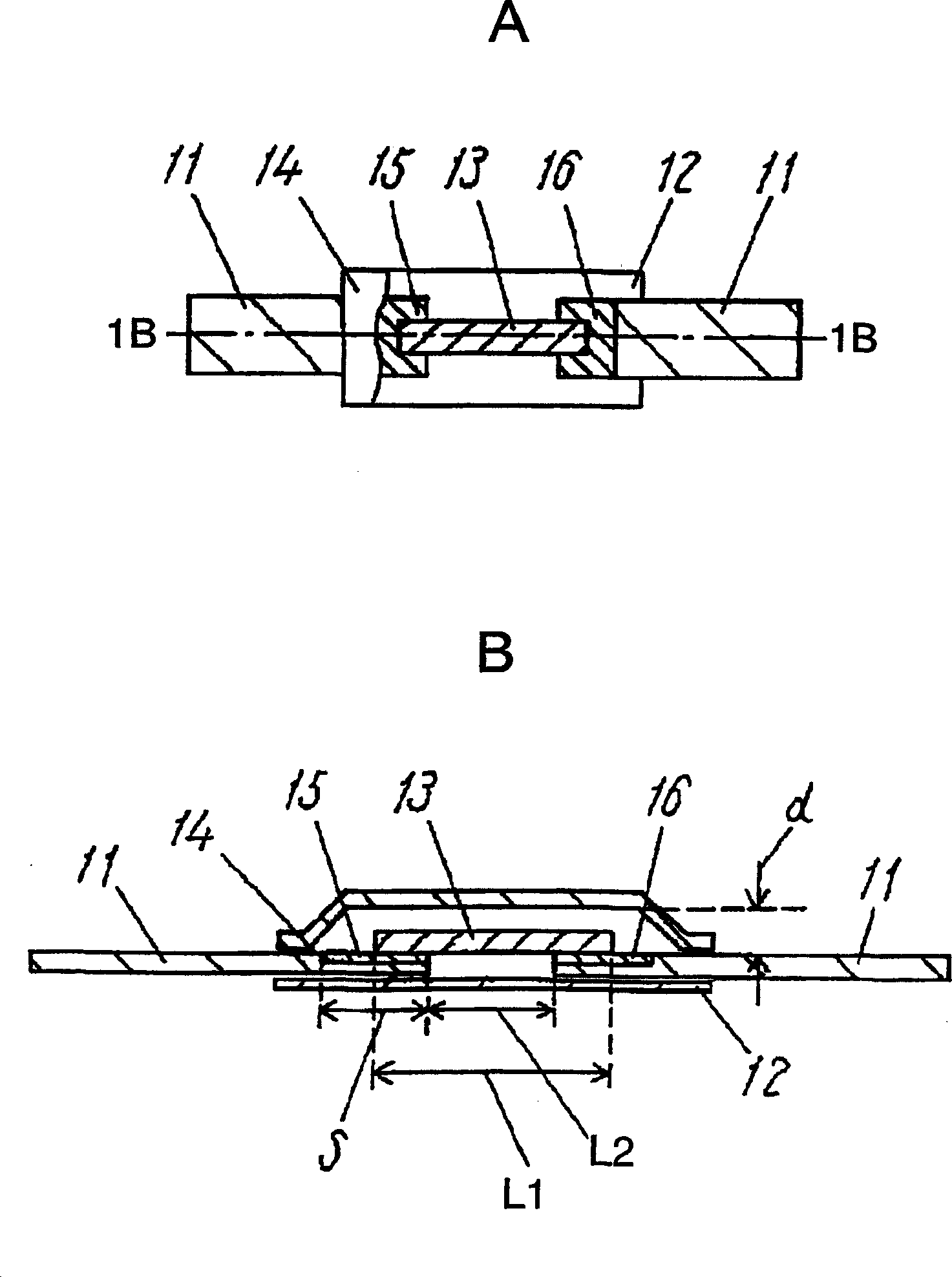

[0027] figure 1 A is a partially cut top view of the thermal fuse in Embodiment 1 of the present invention. figure 1 B is along figure 1 A is a cross-sectional view of the 1B-1B line of the thermal fuse.

[0028] The thermal fuse in Embodiment 1 includes: a first insulating film 12 on which the tip portions of the pair of metal terminals 11 are arranged, and is located above the first insulating film 12 and provided on the tip portions of the pair of metal terminals 11. The soluble alloy 13 in between is located above the soluble alloy 13 and is fixed to the second insulating film 14 on the first film 12 and the metal terminal 11. Metal layers 15 and 16 that are more wettable to the soluble alloy 13 than the metal terminals 11 and the first insulating film 12 and connected to the soluble alloy 13 are provided on the tip portions of the pair of metal terminals 11 .

[0029] Taking the area of the metal layers 15 and 16 as S, the length and volume of the soluble alloy 13...

Embodiment approach 2

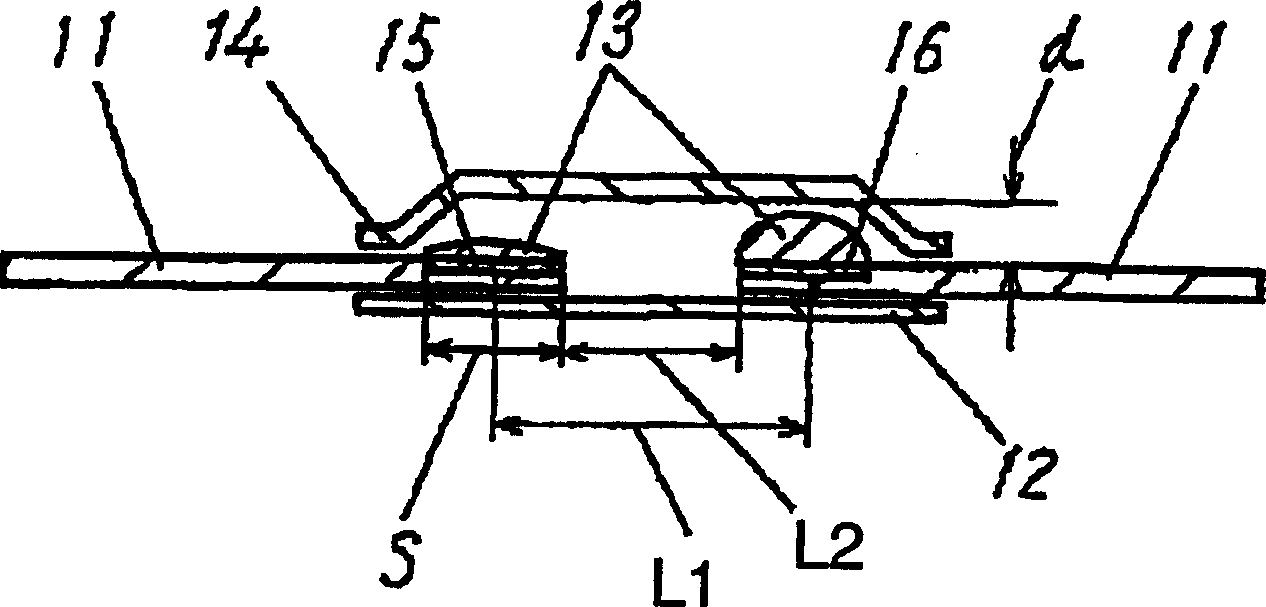

[0057] Figure 4 A is a partially cut top view of the thermal fuse in Embodiment 2 of the present invention. Figure 4 B is along Figure 4 A shows a cross-sectional view of line 4B-4B of the thermal fuse.

[0058] Those having the same configuration as those in Embodiment 1 are denoted by the same symbols and their descriptions are omitted.

[0059] exist Figure 4 In A, the difference from Embodiment 1 is that the tip portions of the pair of metal terminals 11 are formed so as to protrude from the lower surface to the upper surface of the first insulating film 12, and at least a part of the protruding portion is provided with a metal with good wettability. Layers 15, 16.

[0060] In the thermal fuse according to the second embodiment, the metal layers 15 and 16 having better wettability than the metal terminal 11 and the first insulating film 12 are provided on part or all of the protruding portion of the metal terminal 11 . Taking the area of the metal layers 15 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com