Metal dome sheet, its mfg. method, and metal dome system

A manufacturing method, arched technology, applied in contact forms, emergency contact forms, movable contacts, etc., can solve problems such as increased number of parts, increased assembly processes, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiment of the invention

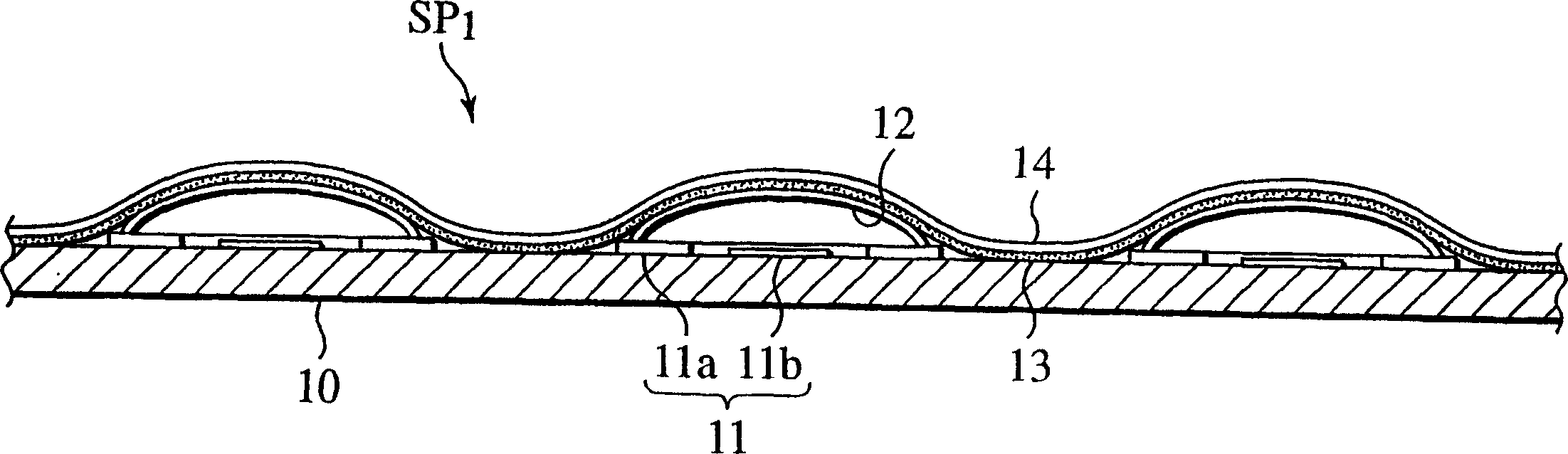

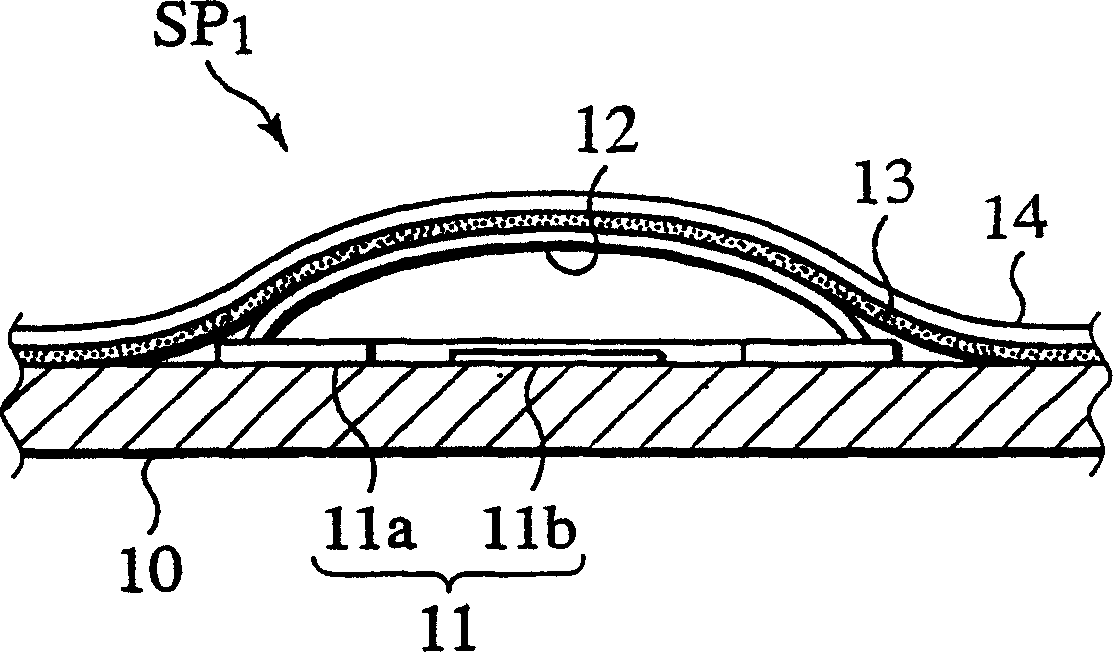

[0033] Figure 7 An example of a thin operation switch panel using the metal dome film of the present invention is shown.

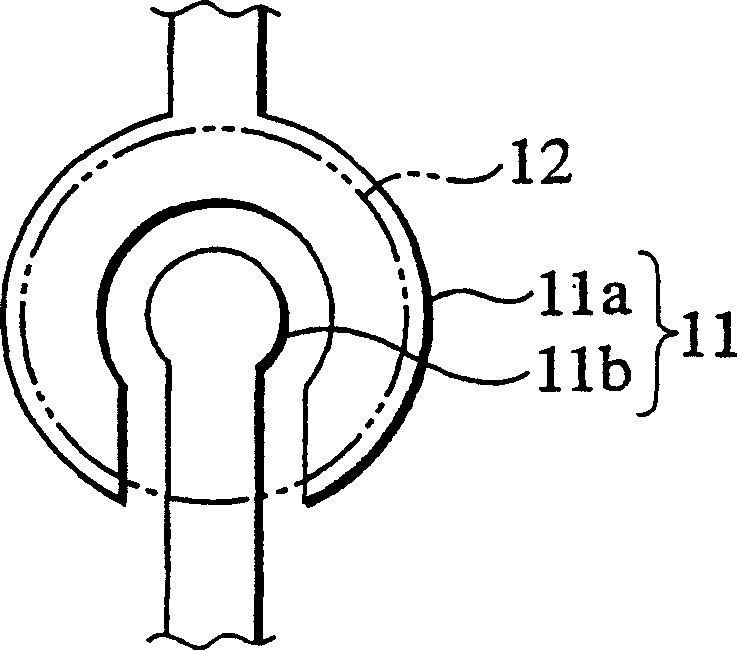

[0034] The Switch Panel SP3 is basically the same as figure 1 The structure of the switch panel shown is substantially the same, however, the structure of the adhesive layer 23 formed on the side of the metal dome film 24A is quite different. In addition, the substrate 10, the electrode portion 11, the metal arch piece 12 and figure 1 The structure shown is the same.

[0035] In short, the metal dome sheet film 24A of the present invention is made of a film such as a polyethylene terephthalate film, such as Figure 8 , Figure 9 As shown, at least an adhesive layer removal portion 23a is provided on the adhesive layer 23 portion between two adjacent metal arcuate sheets 12, 12 to form a channel as an air release portion (channel) δ.

[0036] Thus, for example, when a user Figure 7 When the metal arched sheet 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com