Wirewound device

A winding device and wire technology, applied in the manufacture of magnetic deflection devices, electrode devices and related components, coil manufacturing, etc., can solve the problem of increased friction between the wire and nozzle, increased wire tension, and inconsistent shape and characteristics of the deflection coil. Stability and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

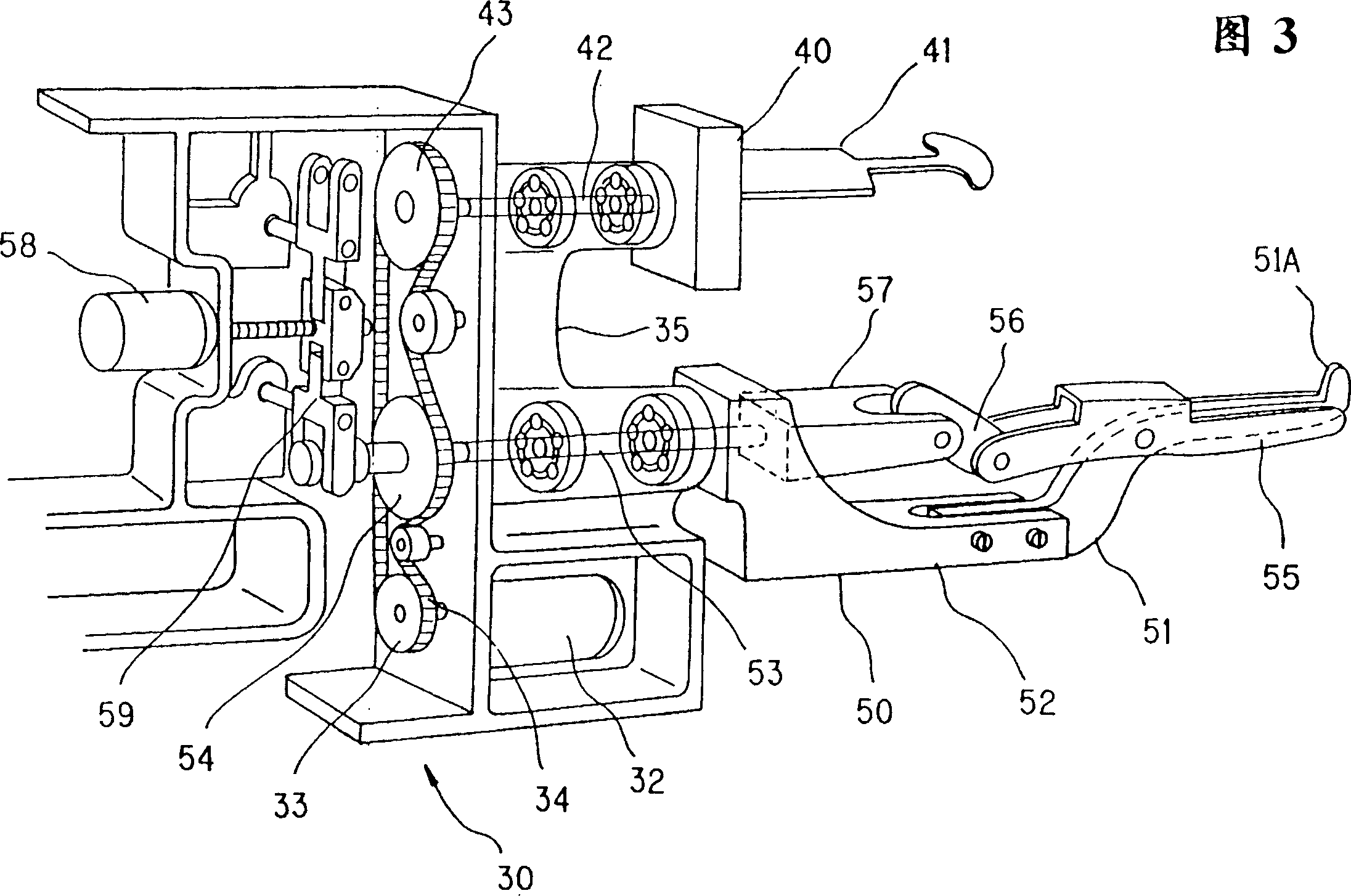

[0034] Embodiments of the present invention will be described below with reference to the drawings.

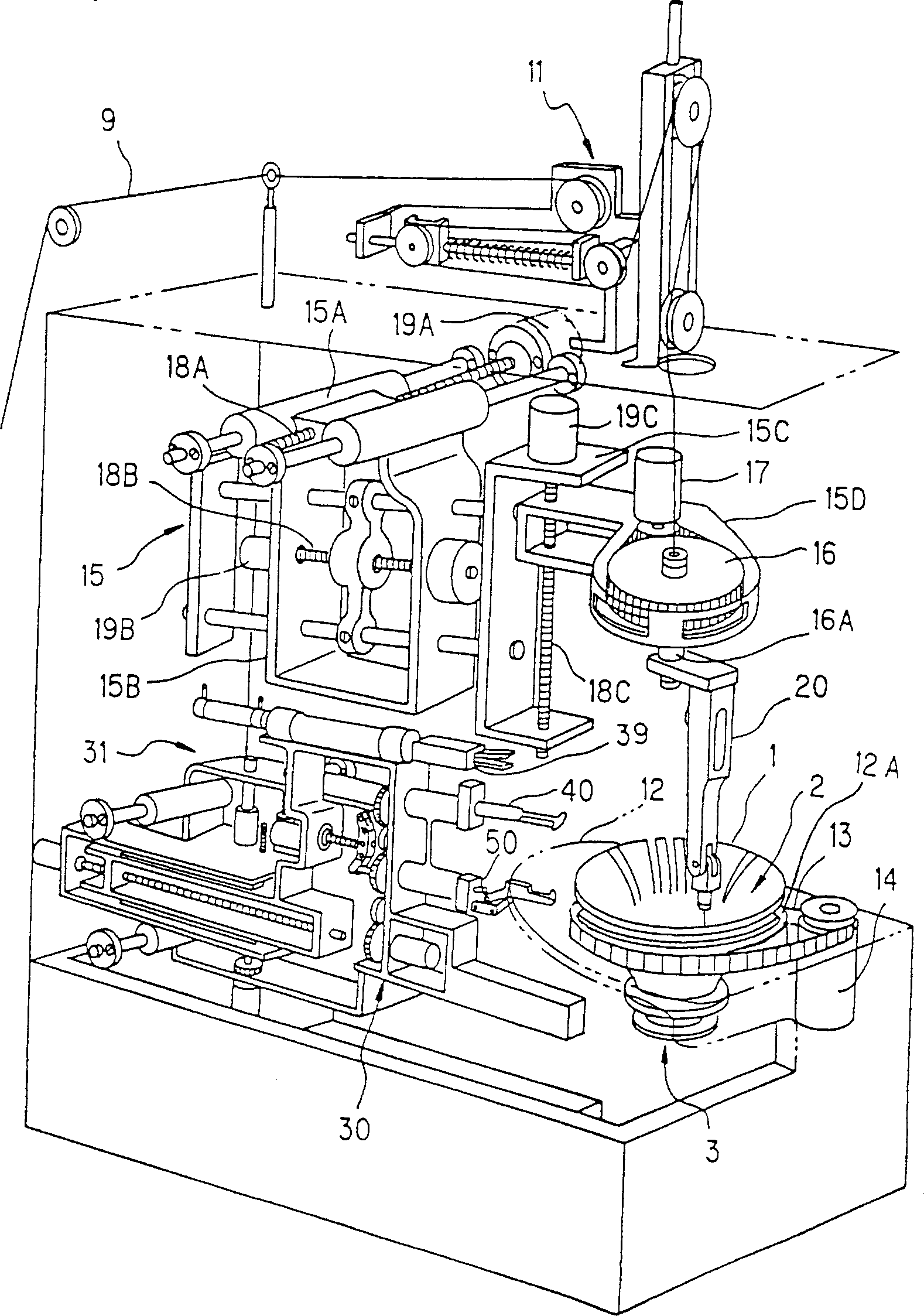

[0035] figure 1 The overall structure of the deflection yoke winding device of the present invention is shown.

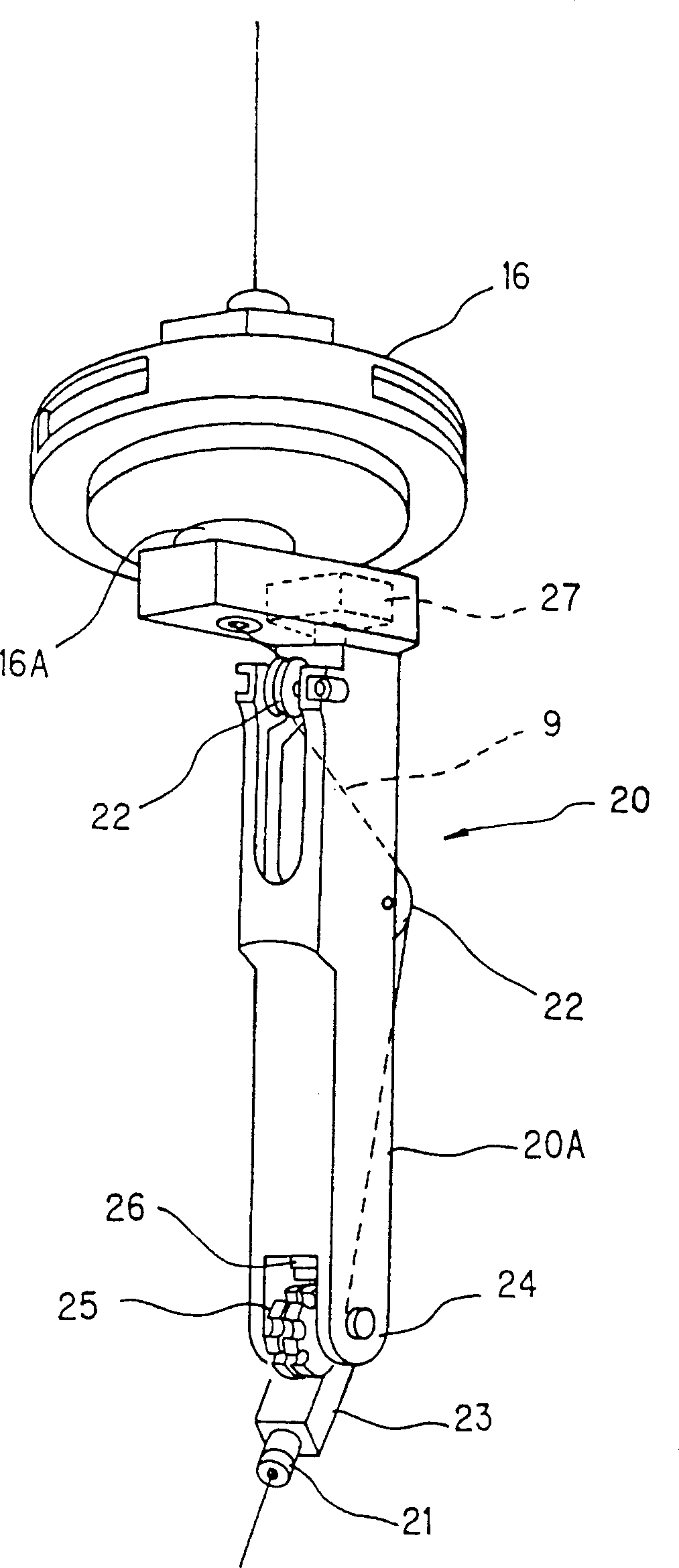

[0036] The wire 9 is drawn out from a bobbin not shown in the figure, and after a predetermined tension is applied to it by a tension device 11, it is guided to a wire supply device 20 below the tension device 11. The wire supply device 20 is disposed above the table-shaped bobbin support part 12 provided on the winding device casing, and the wire 9 extracted from the nozzle 21 at the front end of the wire supply device 20 is guided to the coil frame (deflection coil frame) 1. , On the rotary member 12A of above-mentioned bobbin supporting part 12, have a hole, bobbin 1 fits in this hole from small-diameter opening part 3, and large-diameter opening part 2 is supported by the rotary member 12A of bobbin supporting part 12. Wherein, the structure of the bobbin 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com