Liquid drop ejector and method for detecting/judging abnormality of head

A droplet nozzle and droplet technology, applied in planting methods, agricultural machinery and implements, printing, etc., can solve the problems of expensive detectors, lowering, inability to choose recovery processing, etc., to prevent throughput from being reduced or deteriorated, and reduce uselessness. The effect of ink discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

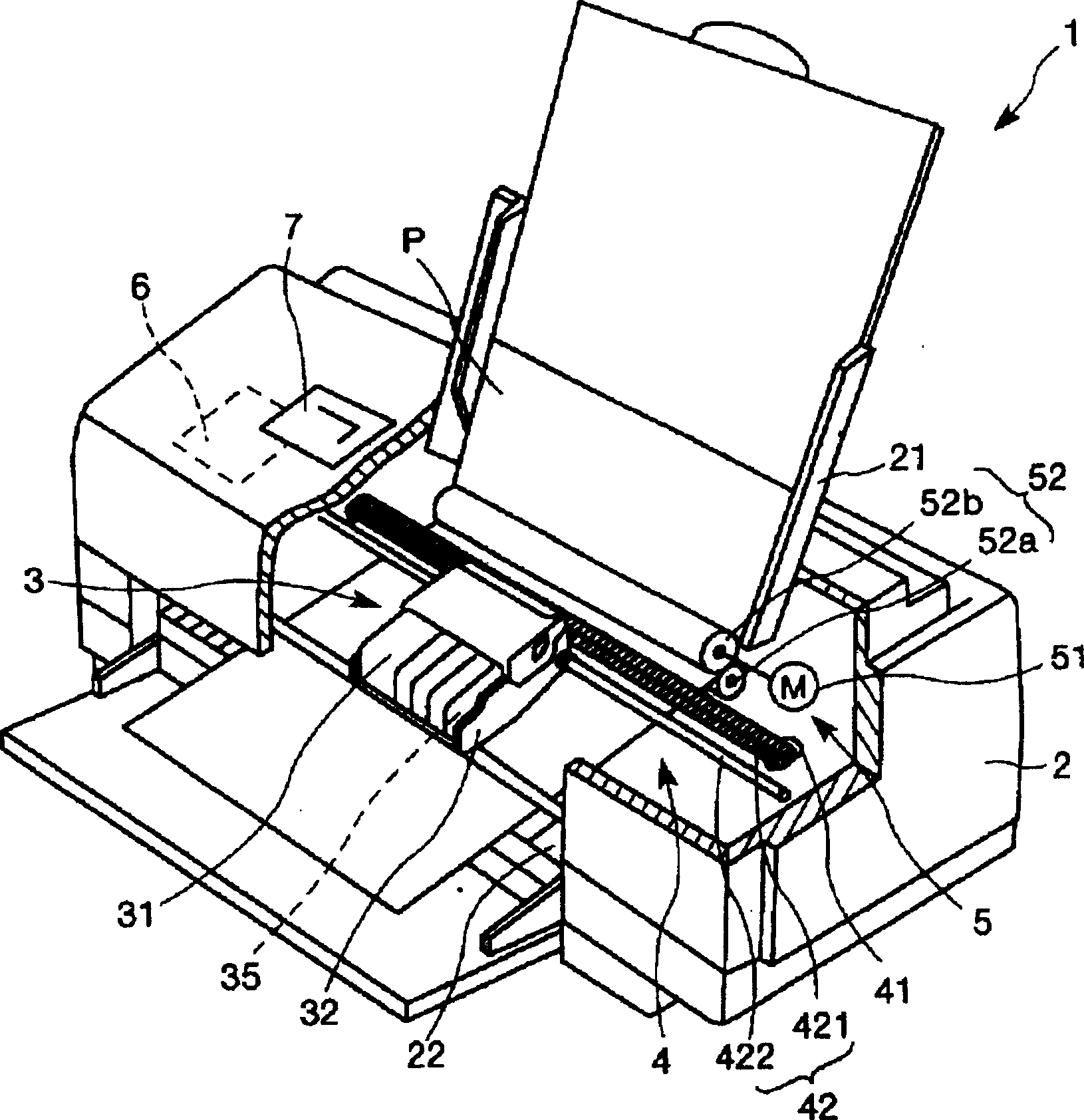

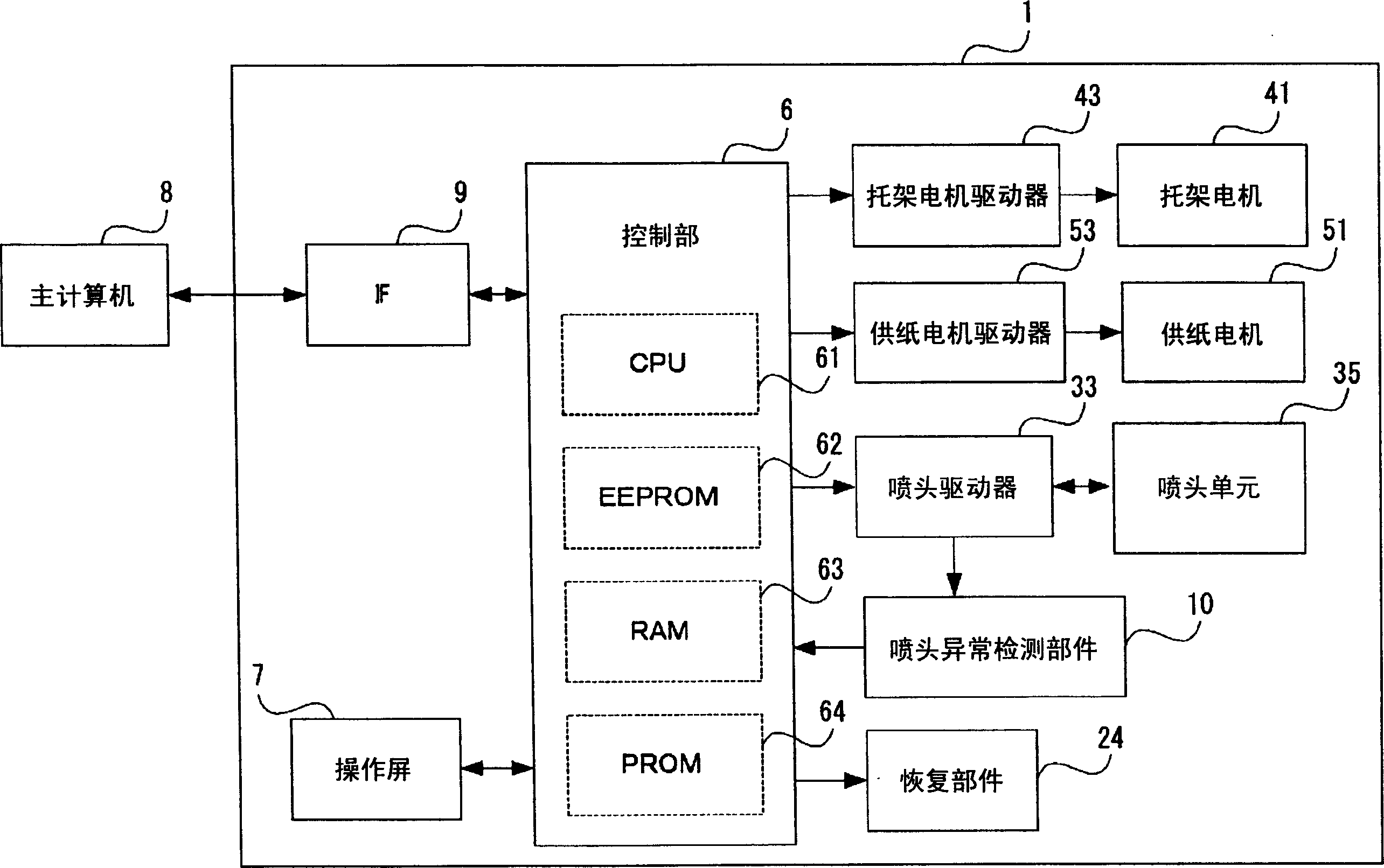

[0134] figure 1 It is a schematic diagram showing the configuration of an inkjet printer 1 which is one type of the droplet ejection device according to the first embodiment of the present invention. In the description below, figure 1 The upper side is called the upper part, and the lower side is called the lower part. First, the configuration of the inkjet printer 1 will be described.

[0135] figure 1 The inkjet printer 1 shown includes a device main body 2, a tray 21 for recording paper P is designed at the upper rear, a paper outlet 22 for sending recording paper P is designed at the lower front, and an operation panel 7 is designed on the upper surface.

[0136] The operation panel 7 is composed of, for example, a liquid crystal display, an organic EL display, LED lights, etc., and includes a display portion (not shown) that displays error messages and the like, and an operation portion (not shown) composed of various switches and the like. The display portion of the ...

no. 2 approach

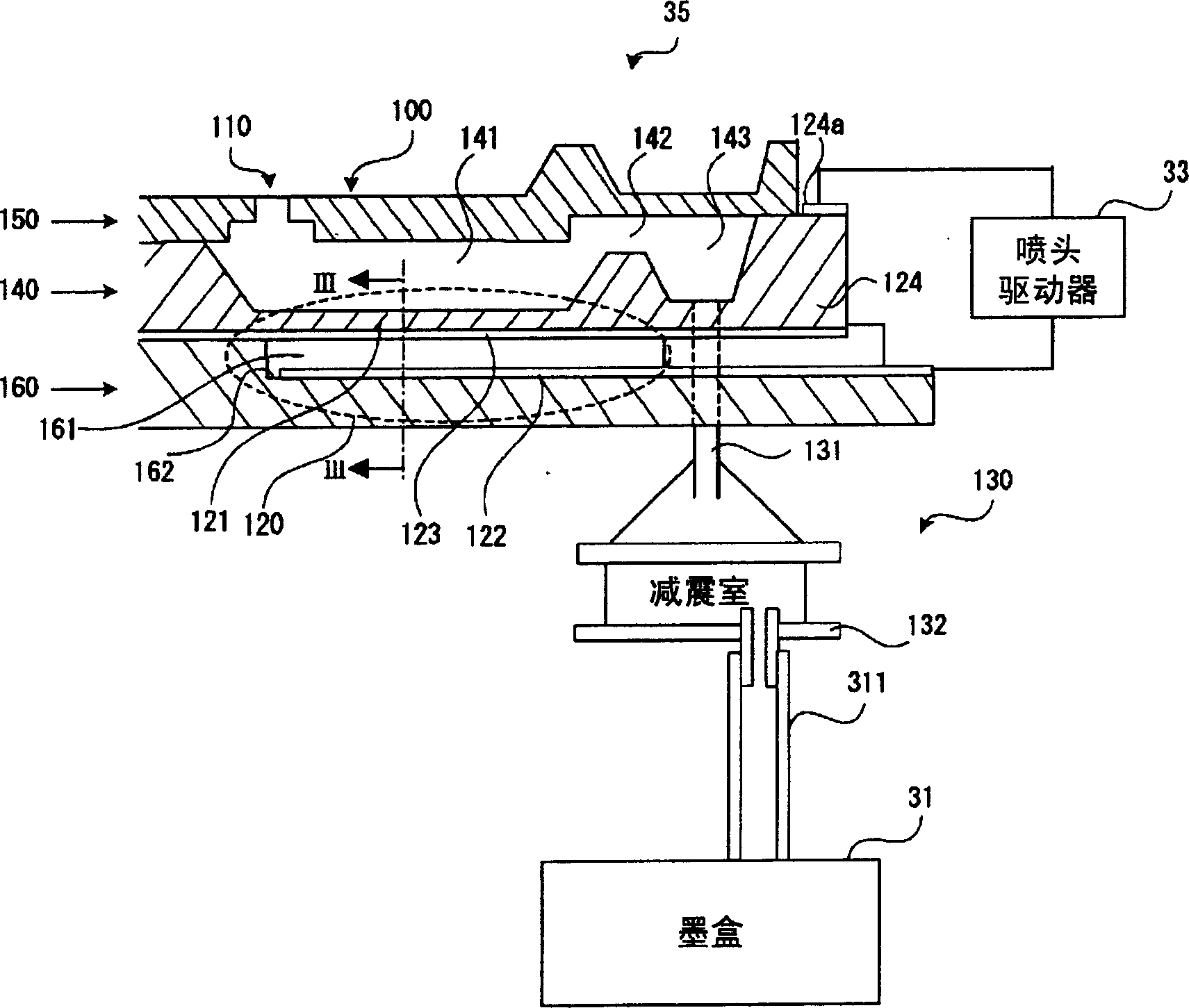

[0357] Next, other structural examples of the inkjet head of the present invention will be described. Figure 44 ~ Figure 47 Each is a schematic cross-sectional view showing another structural example of the inkjet head (head unit). The following description will be made based on these figures, but the description will focus on the differences from the above-mentioned embodiment, and the description of the same items will be omitted.

[0358] Figure 44 In the illustrated inkjet head 100A, the vibration plate 212 is vibrated by driving the piezoelectric element 200 , and the ink (liquid) in the chamber 208 is ejected from the nozzles 203 . On the nozzle plate 202 made of stainless steel forming the nozzle (hole) 203, a metal plate 204 made of stainless steel is bonded via an adhesive film 205, and a metal plate 204 made of stainless steel is also bonded thereon through an adhesive film 205. Further, the communication port forming plate 206 and the chamber plate 207 are bonde...

no. 3 approach

[0374] Next, another structural example of the inkjet head of the present invention will be described. Figure 48 It is a perspective view showing the structure of the head unit 35 of this embodiment, Figure 49 yes Figure 48 A sectional view of the head unit 35 (inkjet head 100H) is shown. The following description will be made based on these figures, but the description will focus on the differences from the above-mentioned embodiment, and the description of the same matters will be omitted.

[0375] Figure 48 and Figure 49 The shown head unit 35 (inkjet head 100H) is based on a so-called film boiling inkjet method (thermal jet method), and a support plate 410, a substrate 420, an outer wall 430, a partition plate 431, and a top plate 440 Figure 48 and Figure 49 Glue in order from the bottom side.

[0376] The base plate 420 and the top plate 440 are provided at predetermined intervals via the outer wall 430 and a plurality of (six in the example in the drawing) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com