Method for cooling turbomachine and turbomachine for applicating the same method

A technology for cooling turbines and turbines, which is applied to the cooling of engines, gas turbine devices, machines/engines, etc., and can solve the problems of stopping the cooling effect and increasing the cost of separate pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

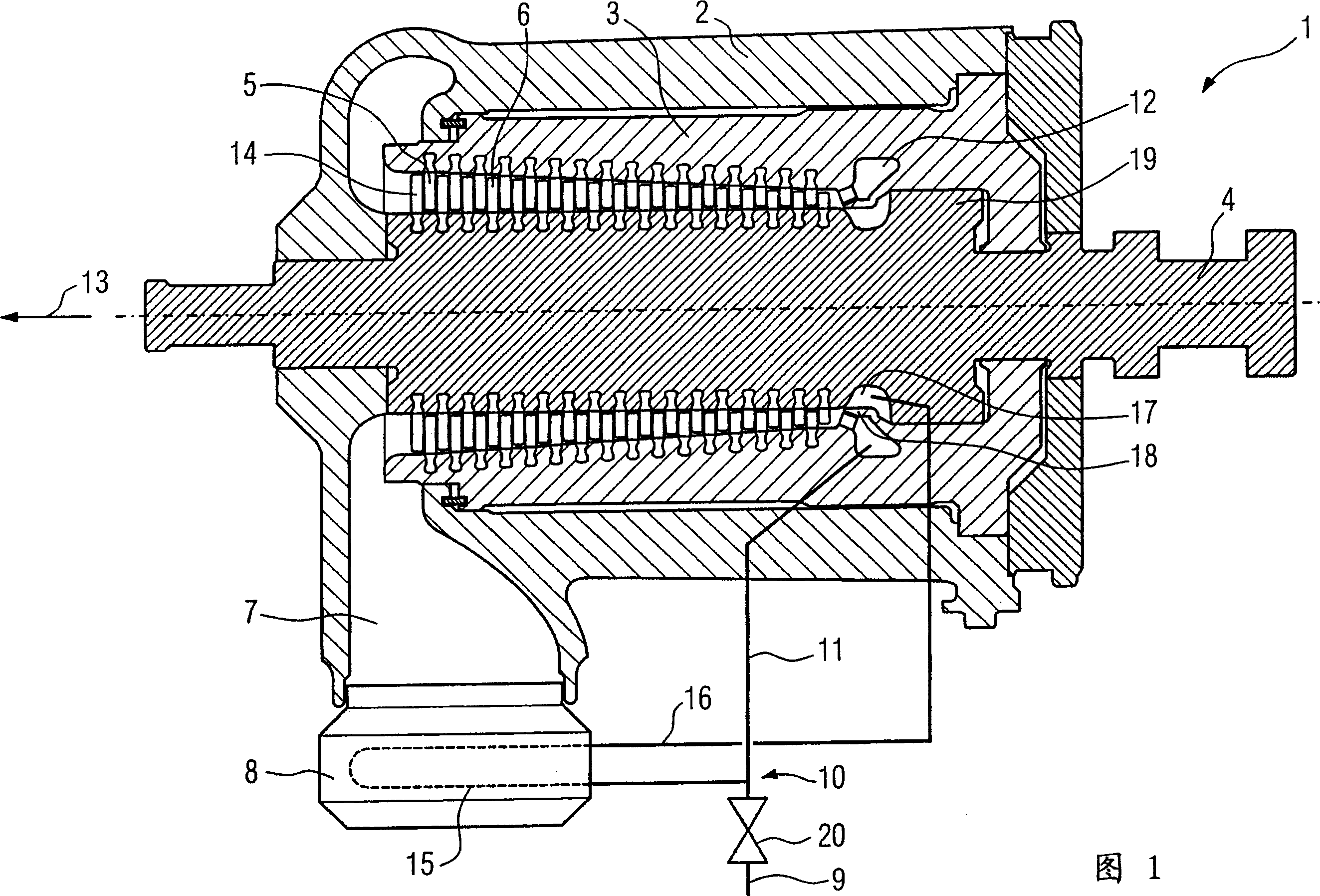

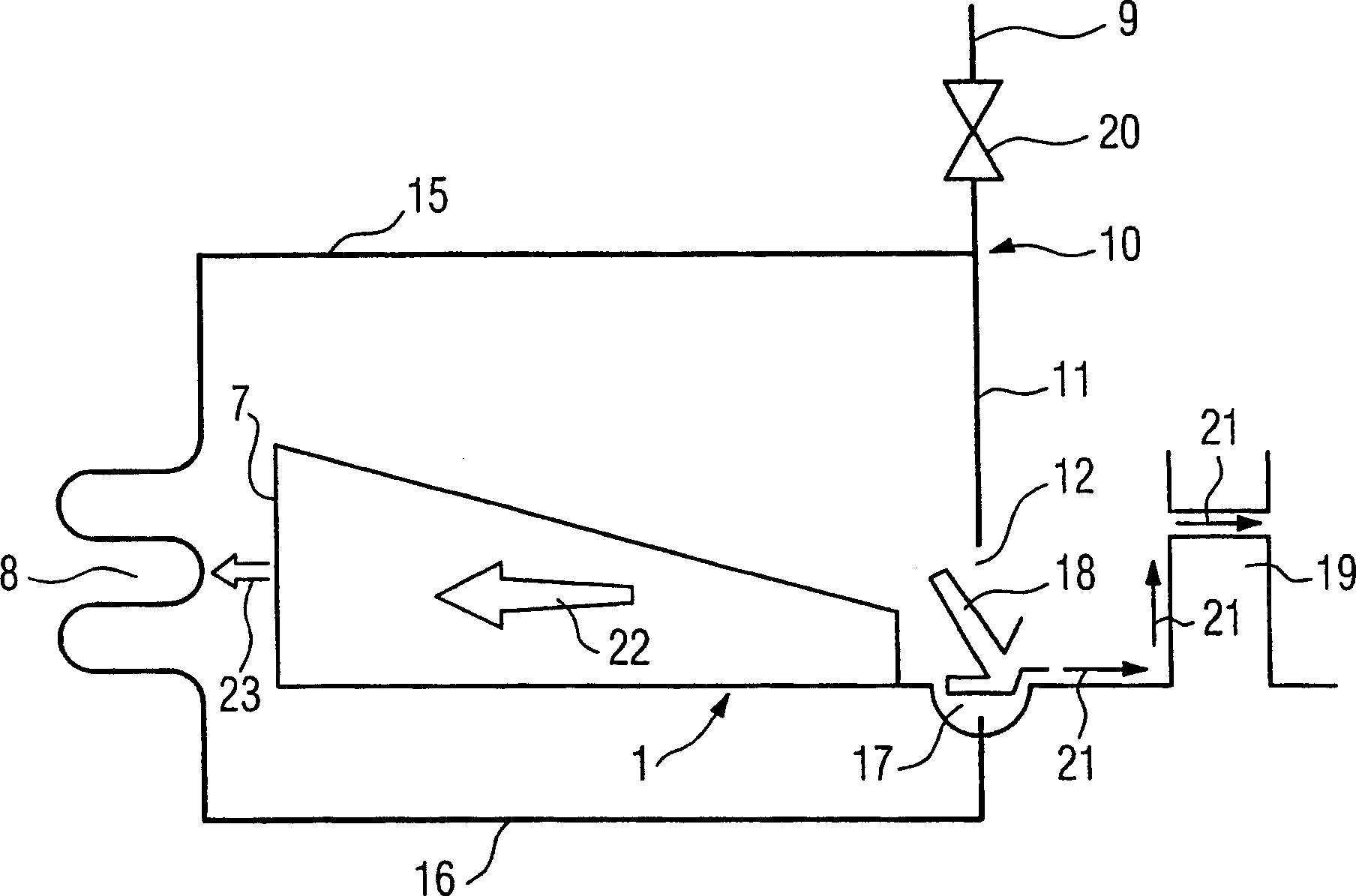

[0019] FIG. 1 shows a turbine 1 . The turbine 1 has a housing 2 . An inner housing 3 is arranged such that a shaft 4 can rotate in said inner housing 3 . The inner housing 3 has guide vanes 5 . The shaft 4 then has rotor blades 6 . A heat exchanger 8 is installed in the waste steam region 7 . The heat exchanger 8 also does not necessarily have to be arranged in the exhaust steam region of the turbine 1 .

[0020] The live steam is fed from a steam boiler (not shown) via the live steam supply line 9 to the turbine 1 . At the split point 10 a part of the live steam is led to the heat exchanger 8 . The temperature of the fresh steam can reach 565° C. and the pressure can reach 250 bar before being diverted at the split point 10. The remaining live steam, ie the live steam not directed to the heat exchanger 8 , enters the turbine 1 via a line 11 . At this point, the live steam reaches the live steam inflow region 12 , and the flow medium flows from the live steam inflow reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com