Counter weight mounting structure for building machinery

A technology for installing structures and construction machinery, which is used in construction, cranes, earthmovers/shovels, etc., and can solve problems such as reduced sound insulation performance, separation or damage of sound insulation materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

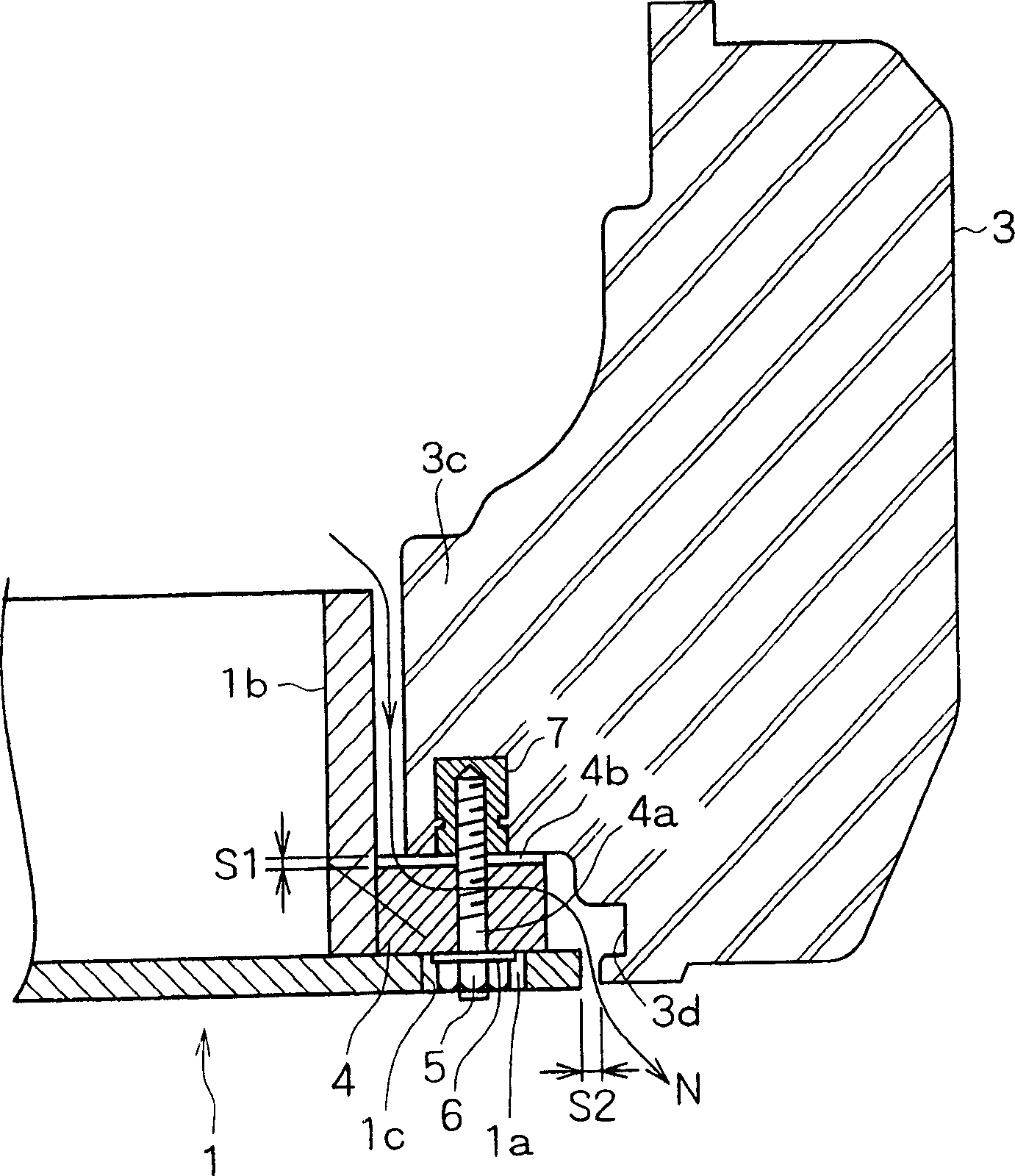

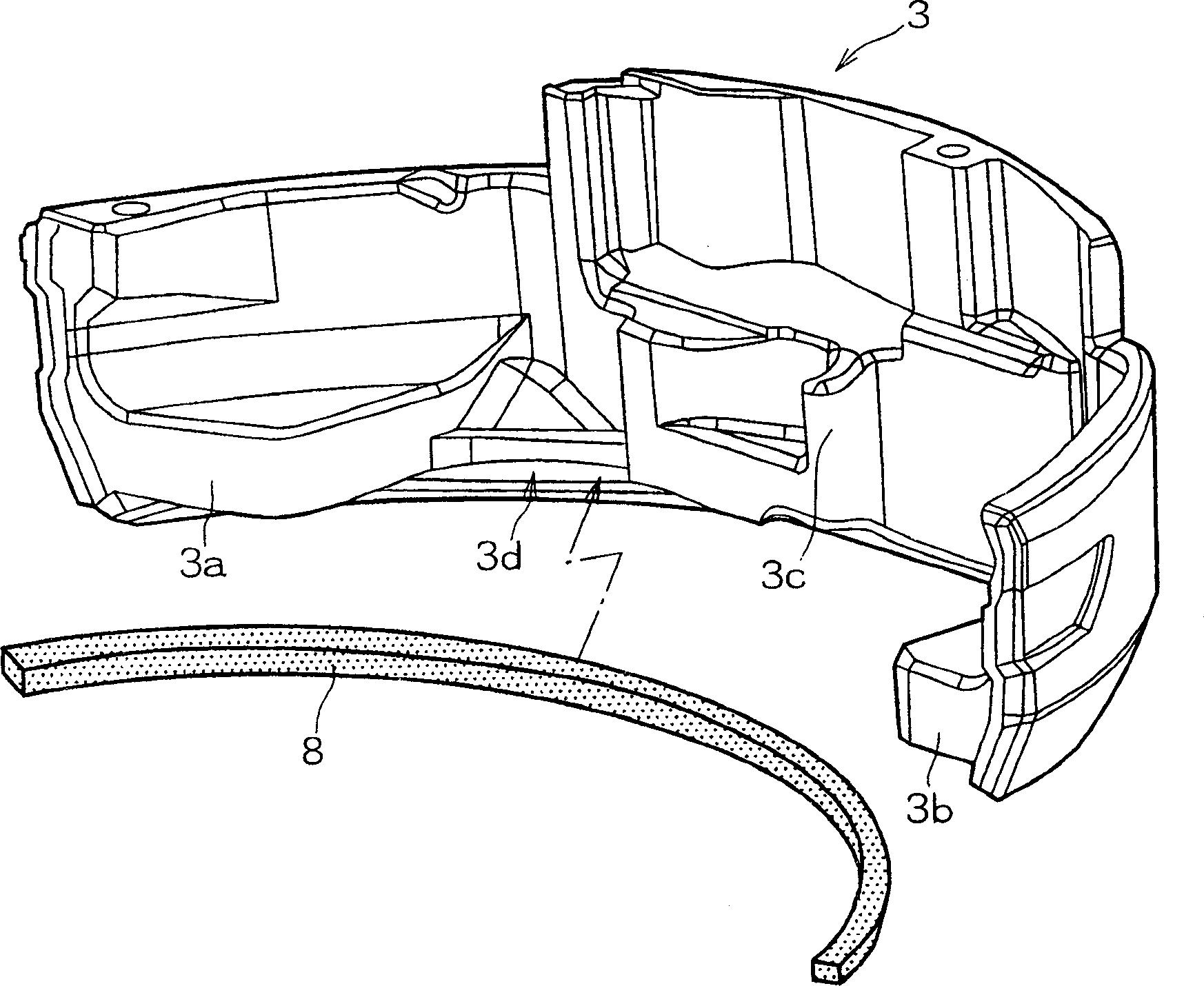

[0019] A counterweight mounting structure for a construction machine according to the present invention will be described based on FIGS. 1 to 8 related to the following embodiments.

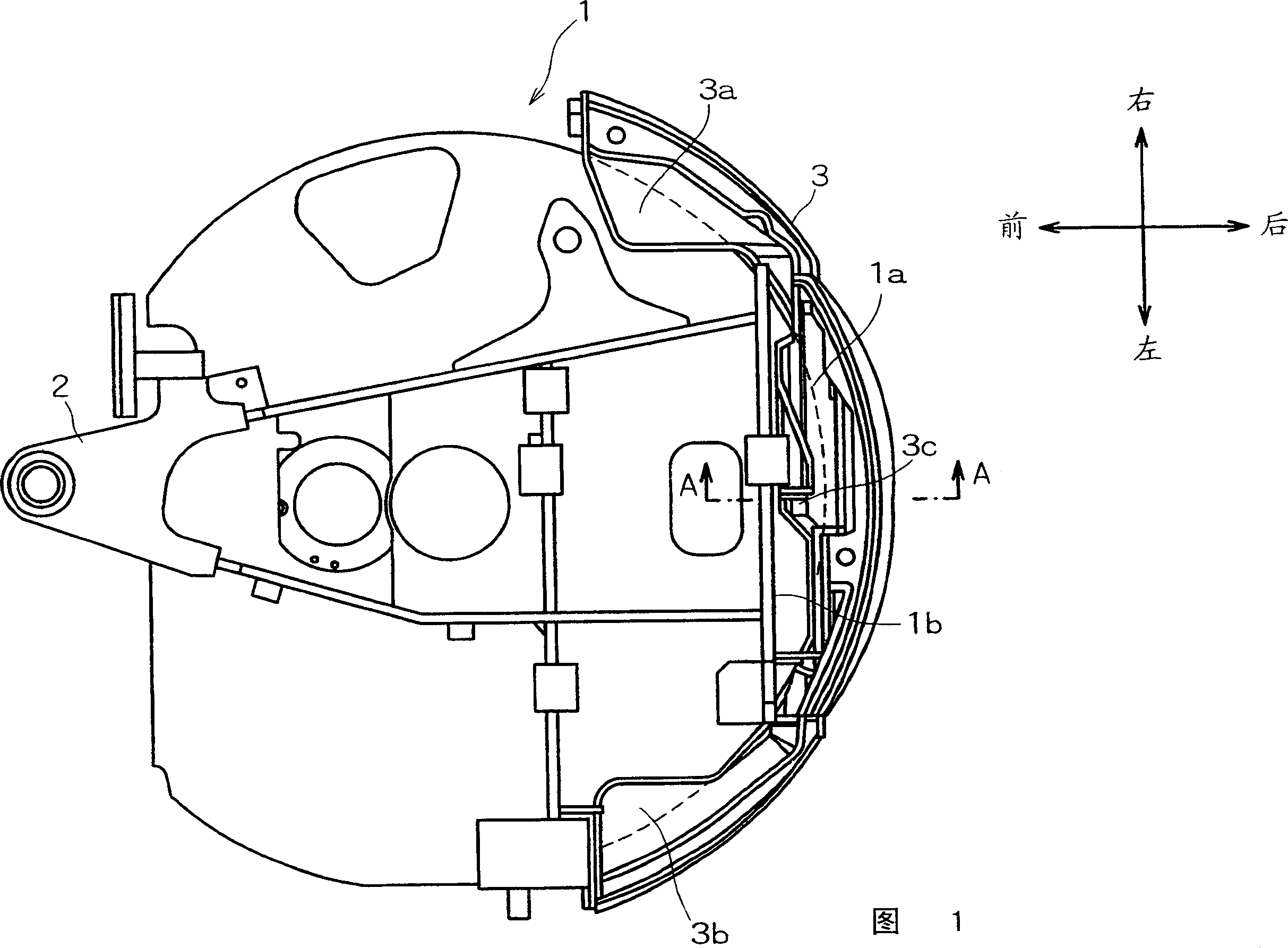

[0020] Hereinafter, a hydraulic excavator will be described as an example of a construction machine. The hydraulic excavator is configured by rotatably attaching an upper rotating body to a lower traveling body. A working device consisting of a bucket, an arm, and a boom is pivotally supported on the front of the upper rotating body, and a counterweight is mounted on its rear or tail. Fig. 1 is a plan view showing the arrangement of a counterweight and a rotating frame to which the present invention is applied.

[0021] The swivel frame 1 shown in Figure 1 is used for an excavator with a short rear swivel (space) radius, when the overhanging tail of the tracked vehicle has zero swivel, or is capable of swiveling in most cases of use at the job site , not protruding from the rear of the tracked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com