Headlamp for vehicle

A technology for headlights and vehicles, which is applied in the direction of vehicle lighting systems, headlights, vehicle components, etc. It can solve the problems of deformation of light-emitting chips, inability to effectively suppress glare, and inability to clearly form horizontal lines, etc., to achieve the goal of suppressing glare Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the drawings.

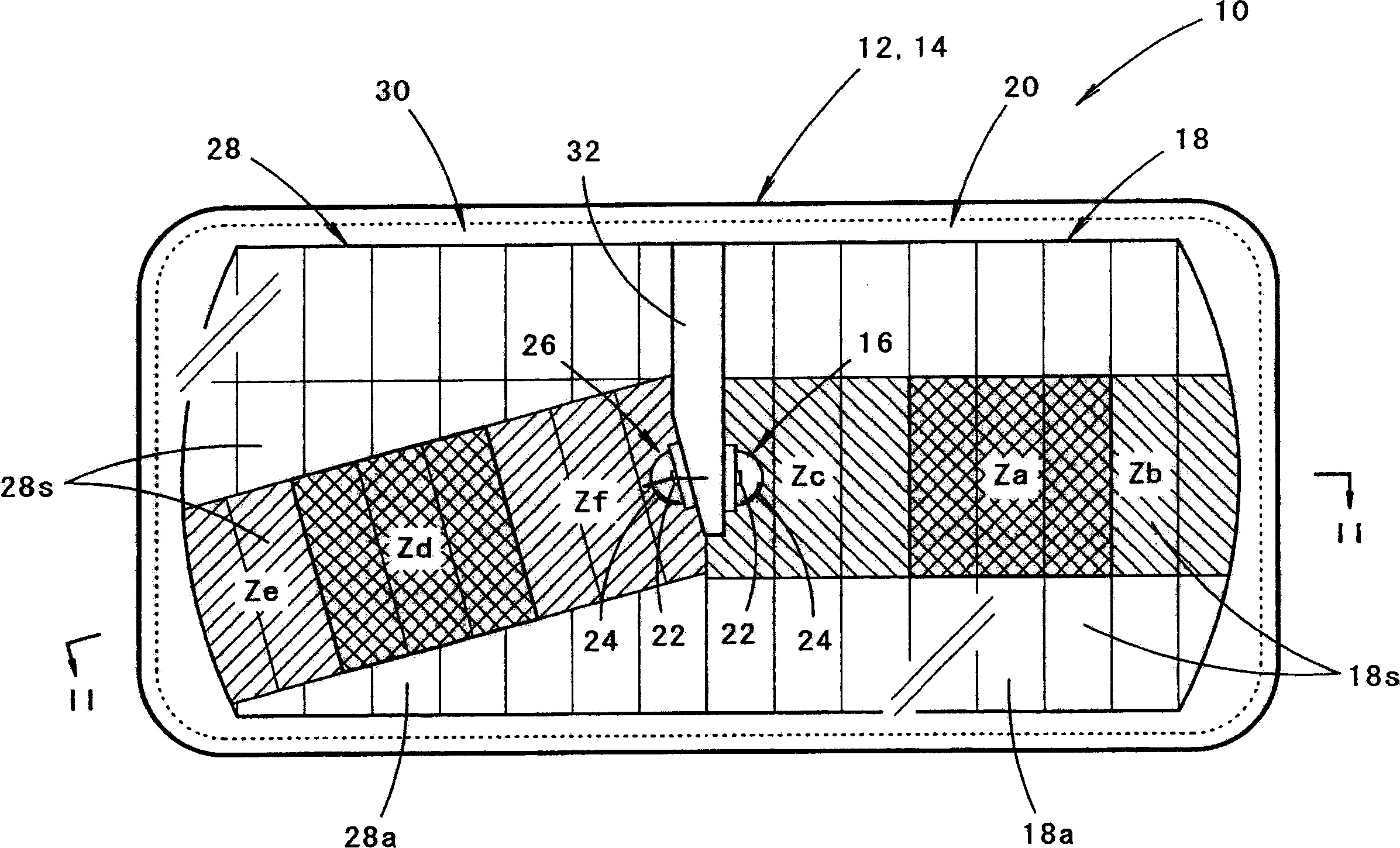

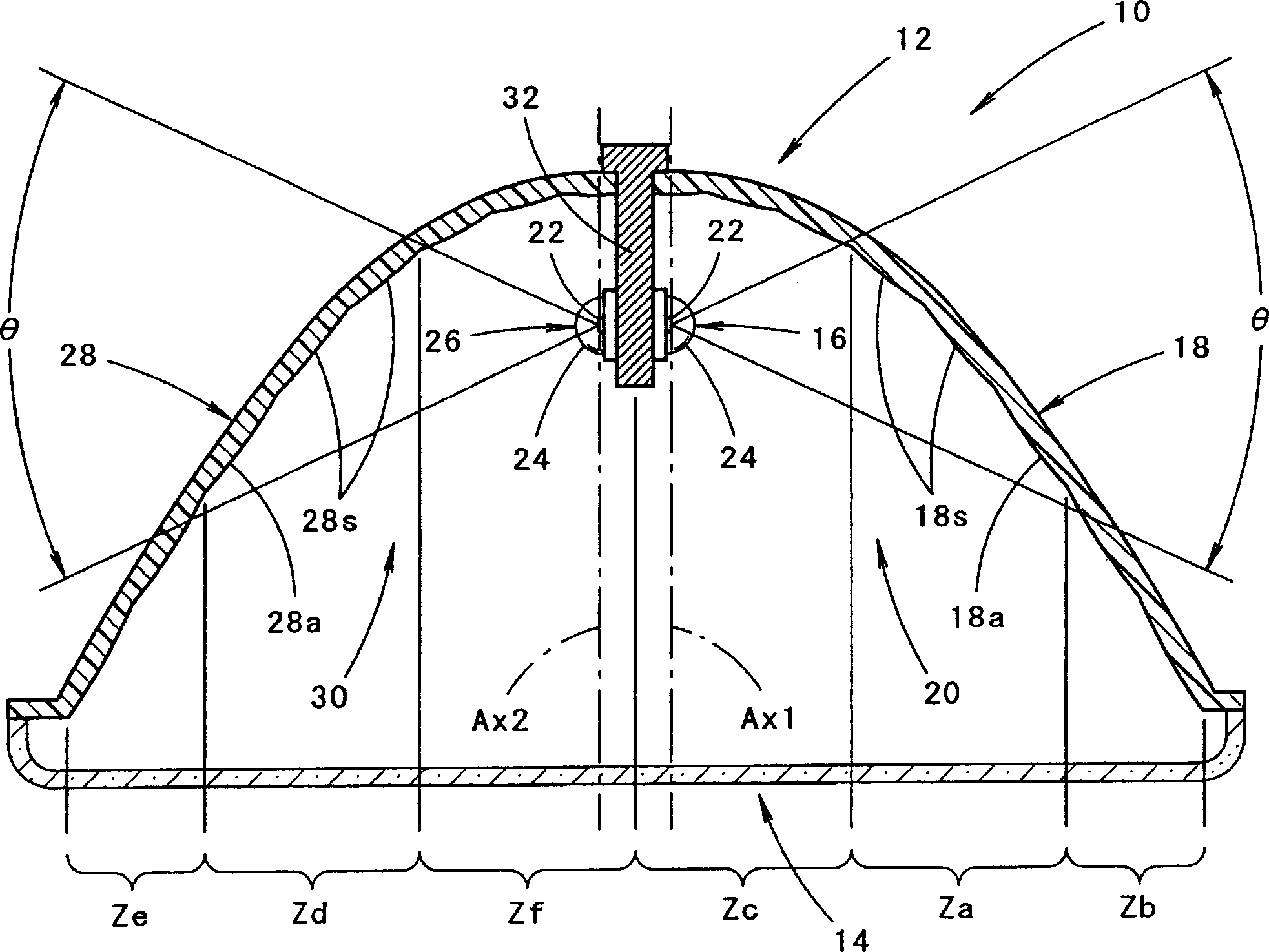

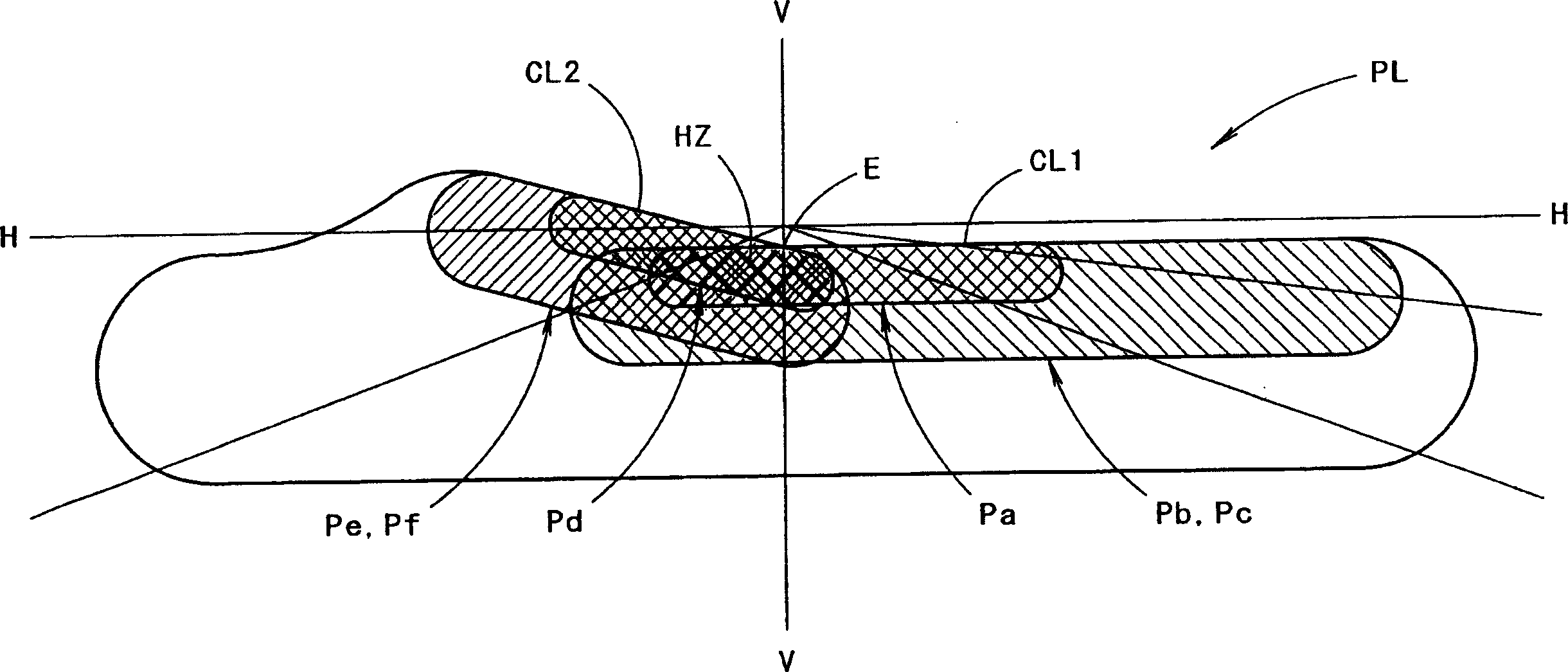

[0032] figure 1 is a front view showing a vehicle headlamp according to an embodiment of the present invention, figure 2 yes means figure 1 The II-II line profile.

[0033] The vehicle headlamp 10 is a lamp configured to form an illumination pattern for low beam, and includes a reflector unit 12 and a transparent translucent cover 14 attached to the front end opening of the reflector unit 12 .

[0034] The reflector unit 12 has a first reflective optical system 20 including a first light source 16 and a first reflector 18 , and a second reflective optical system 30 including a second light source 26 and a second reflector 28 . Both the first and second light sources 16 , 26 are constituted by light emitting diodes formed by covering a rectangular light emitting chip 22 with a hemispherical mold lens 24 , and are supported by a common holder 32 . In addition, the first and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com