Cylinder washing machine

A drum washing machine and washing water technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of increasing power consumption, prolonging working time, and complicated production processes, and achieves the reduction of the number of motors and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

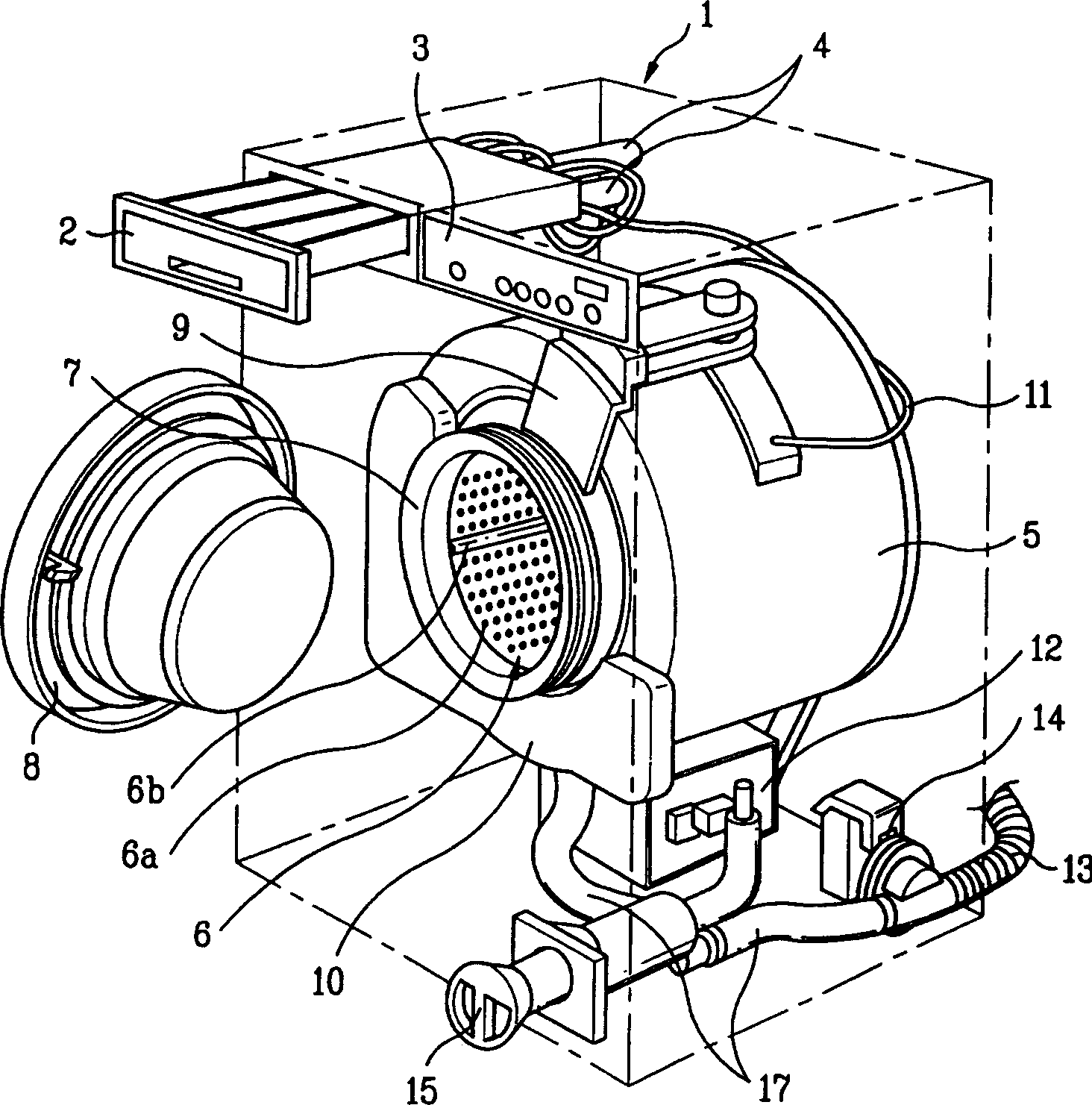

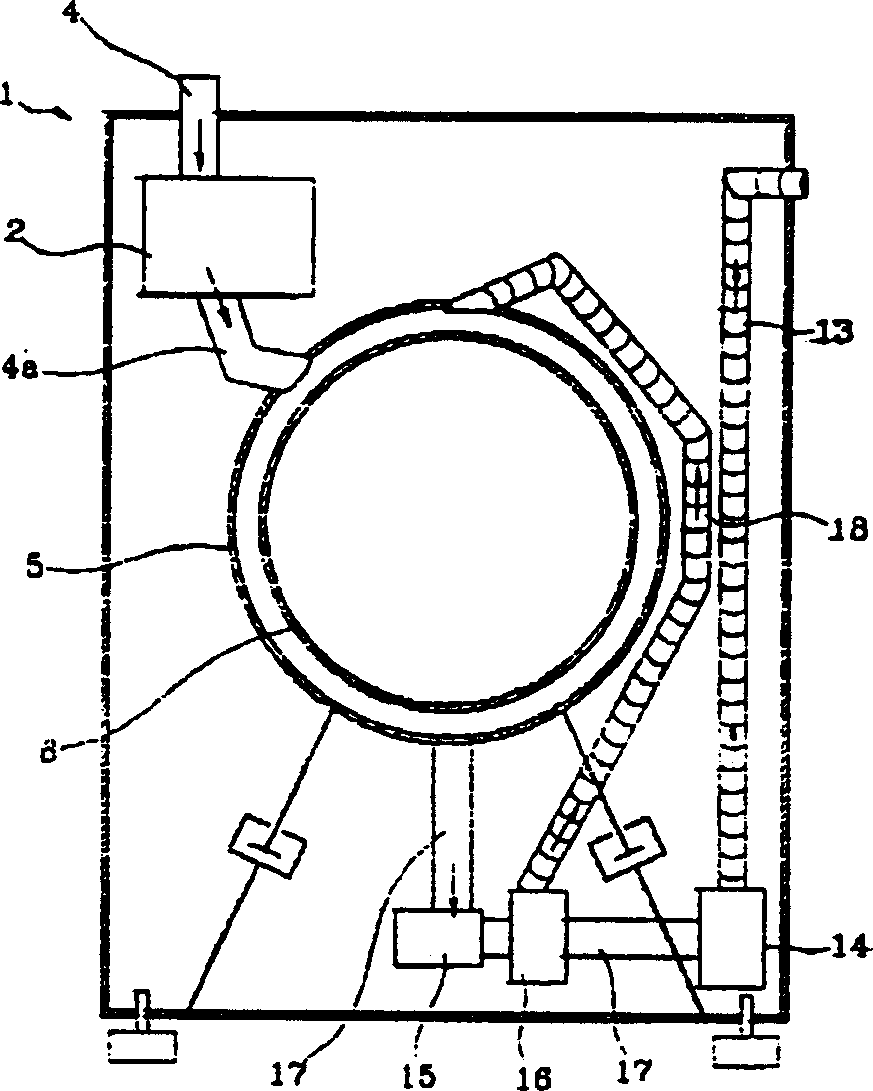

[0037] Referring to the accompanying drawings, the drum washing machine of the present invention will be described in detail below.

[0038] In order to avoid repetition, in the structure of the present invention, the reference symbols of the prior art are used for the parts that are the same as those of the background art.

[0039] Since the general structure of the drum washing machine has been described in detail in the background art, only the characteristic parts different from the prior art will be described in the present invention.

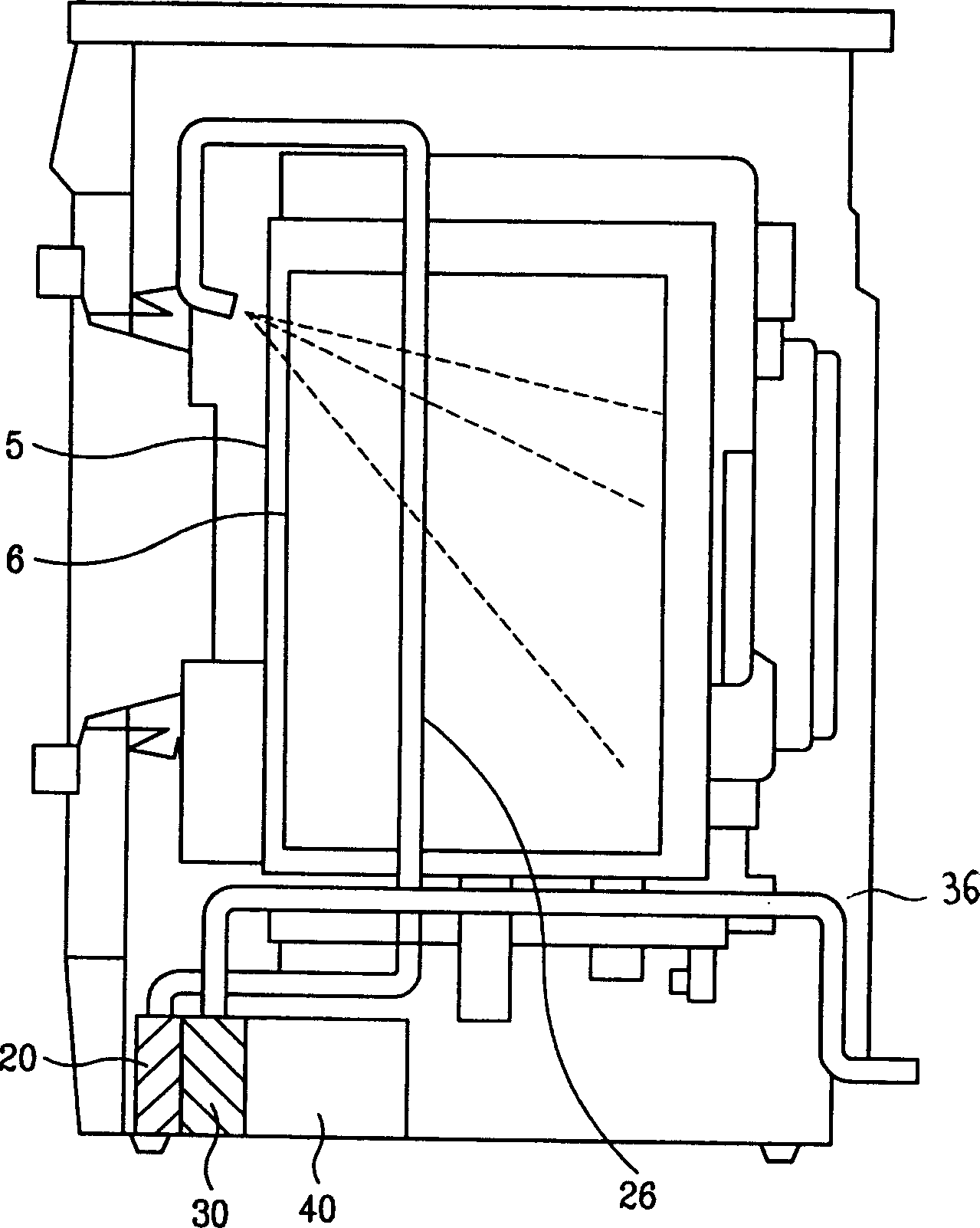

[0040] image 3 A cross-sectional view of a front-loading washing machine according to a first embodiment of the present invention is briefly shown. Figure 4 A structural diagram of the circulating pump 20, the drain pump 30 and the motor 40 of the present invention is briefly shown.

[0041] Such as image 3 and Figure 4 As shown, a motor 40 is provided on the bottom surface of the washing tub 5 of the front-loading washing machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com