Paralel robot mechanism with bidimension rotating mono-dimension moving

A robot and parallel technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., to achieve the effect of clear motion form, wide application prospects, and simple inverse solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

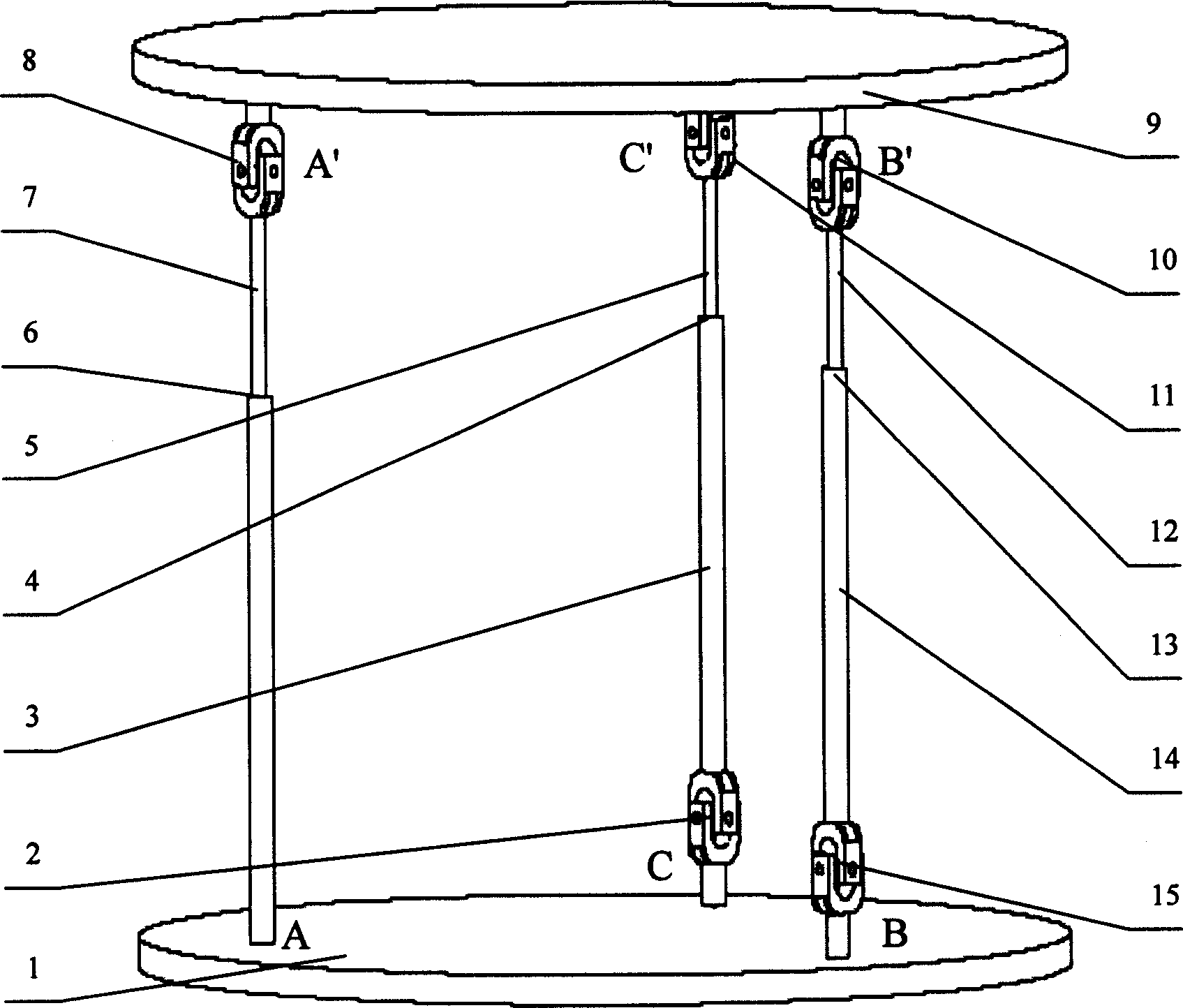

[0024] The overall structure of this embodiment is as figure 1 As shown, the moving platform 9 of this mechanism is connected with the fixed platform 1 through three branches, and these three branches are all telescopic connecting rods. The first branch is composed of connecting rod 3 and connecting rod 5 connected by moving pair 4, connecting rod 3 of this branch is connected with fixed platform 1 through Hooke hinge 2, and connecting rod 5 is connected with moving platform 9 through Hooke hinge 11 The second branch is made up of connecting rod 12 and connecting rod 14 connected by moving pair 13, connecting rod 14 of this branch is connected with fixed platform 1 through Hooke hinge 15, connecting rod 12 is connected with moving platform 9 through Hooke hinge 10 connected; the third branch is composed of a connected moving pair 6 and a connecting rod 7, the moving pair 6 is fixed to the fixed platform 1, and the connecting rod 7 is connected to the moving platform 9 through ...

Embodiment 2

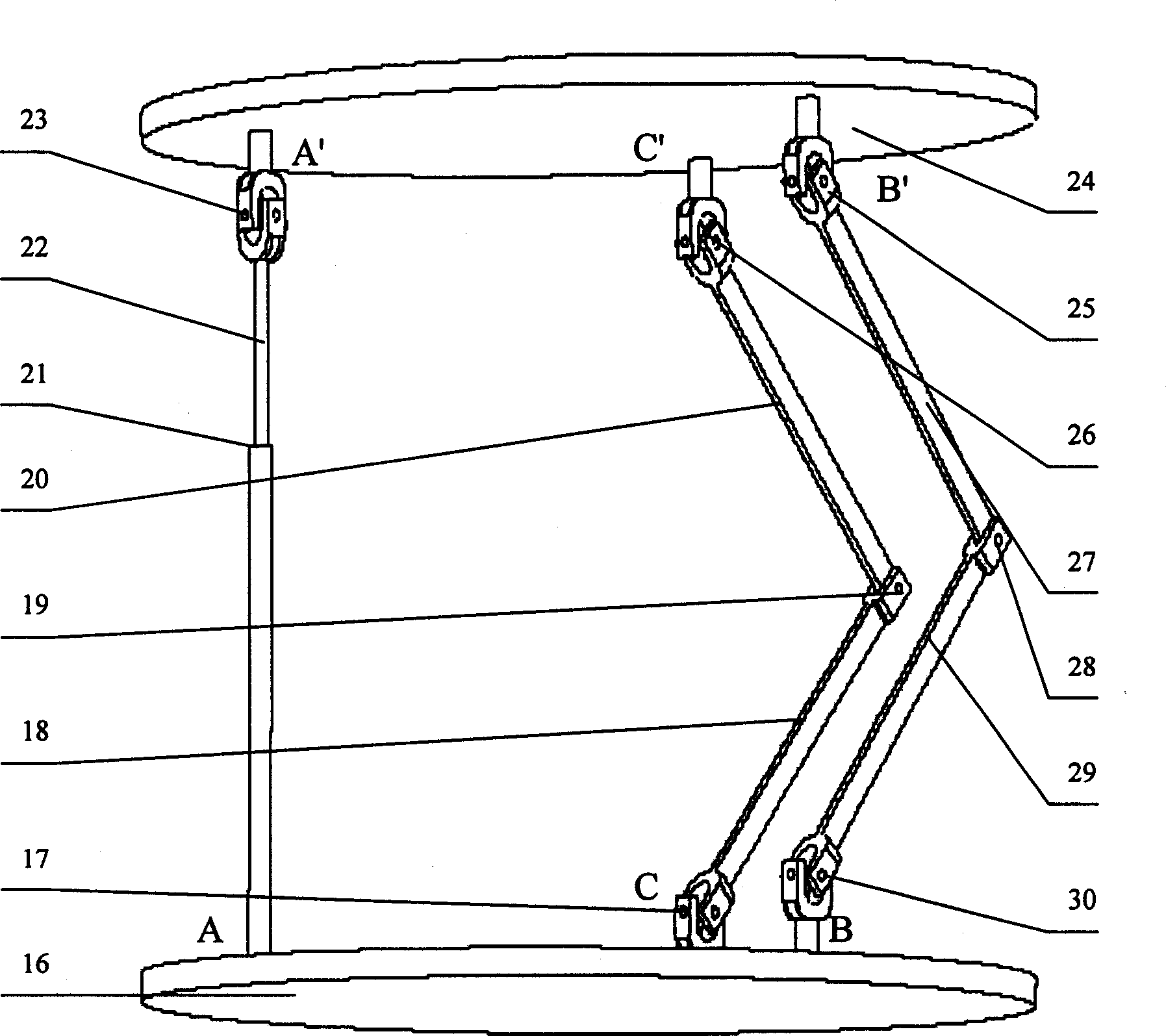

[0027] The overall structure of this embodiment is as figure 2 As shown, the moving platform 24 of this mechanism is connected with the fixed platform 16 through three branches, the first branch is a telescopic connecting rod, and this branch is composed of a connected moving pair 21 and a connecting rod 22, and the moving pair 21 and the fixed The platform 16 is fixed, and the connecting rod 22 is connected with the moving platform 24 through the Hooke hinge 23 . The second branch is made up of connecting rod 18 and connecting rod 20 connected by rotating pair 19. The connecting rod 18 of this branch is connected with fixed platform 16 through Hooke hinge 17, and connecting rod 20 is connected with moving platform 24 through Hooke hinge 26. Connected, the rotation axis of the rotating pair 19 between the connecting rod 18 and the connecting rod 20 is parallel to the corresponding rotating axes on the Hooke hinge 17 and the Hooke hinge 26 respectively; The connecting rod 29 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com