Oil skimmer of two toothed rolls

A technology of double-toothed rollers and oil skimmers, which is applied in water conservancy projects, cleaning of open water surfaces, and general water supply conservation, etc., to achieve good adaptability, follow the waves, and improve the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

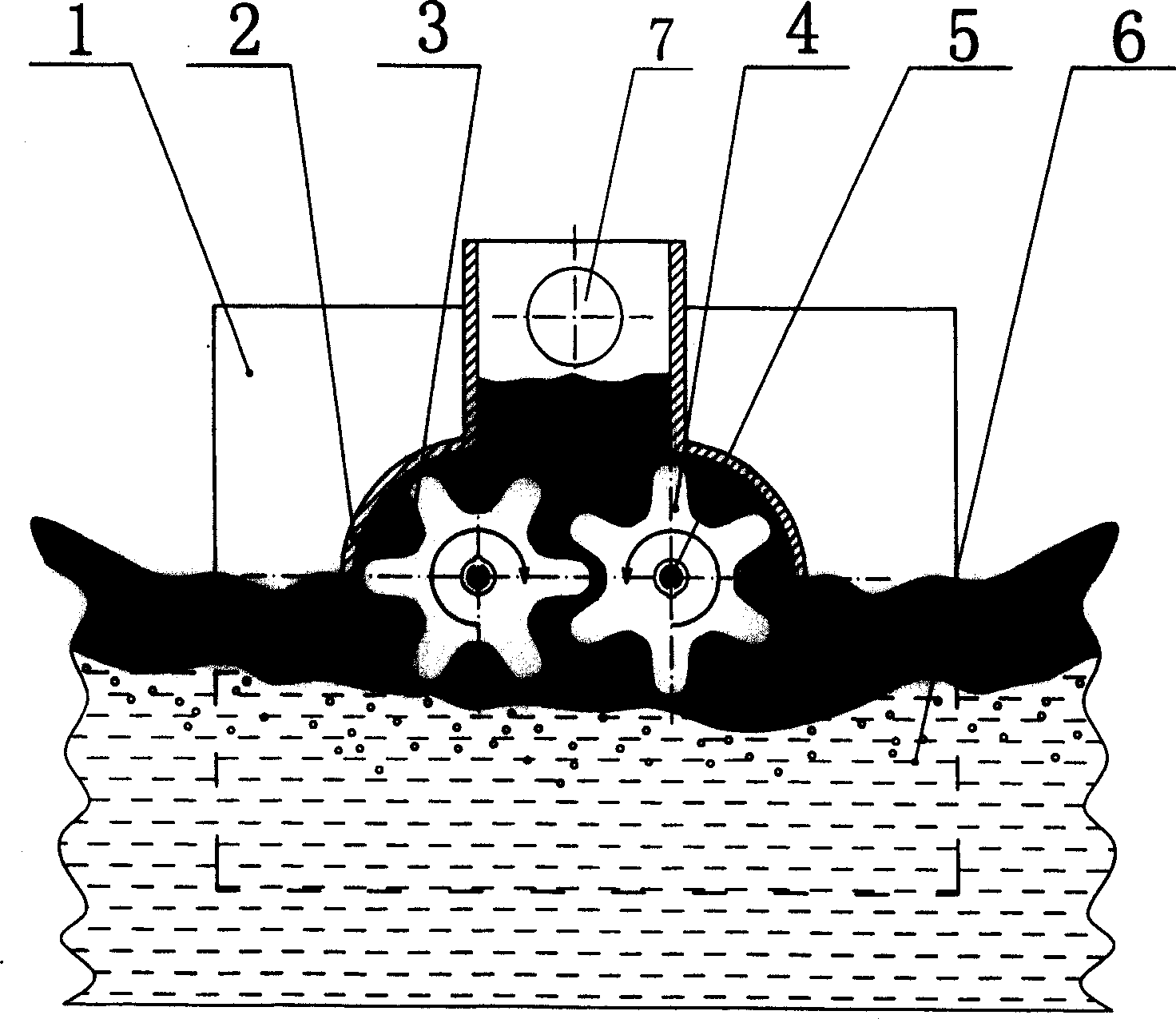

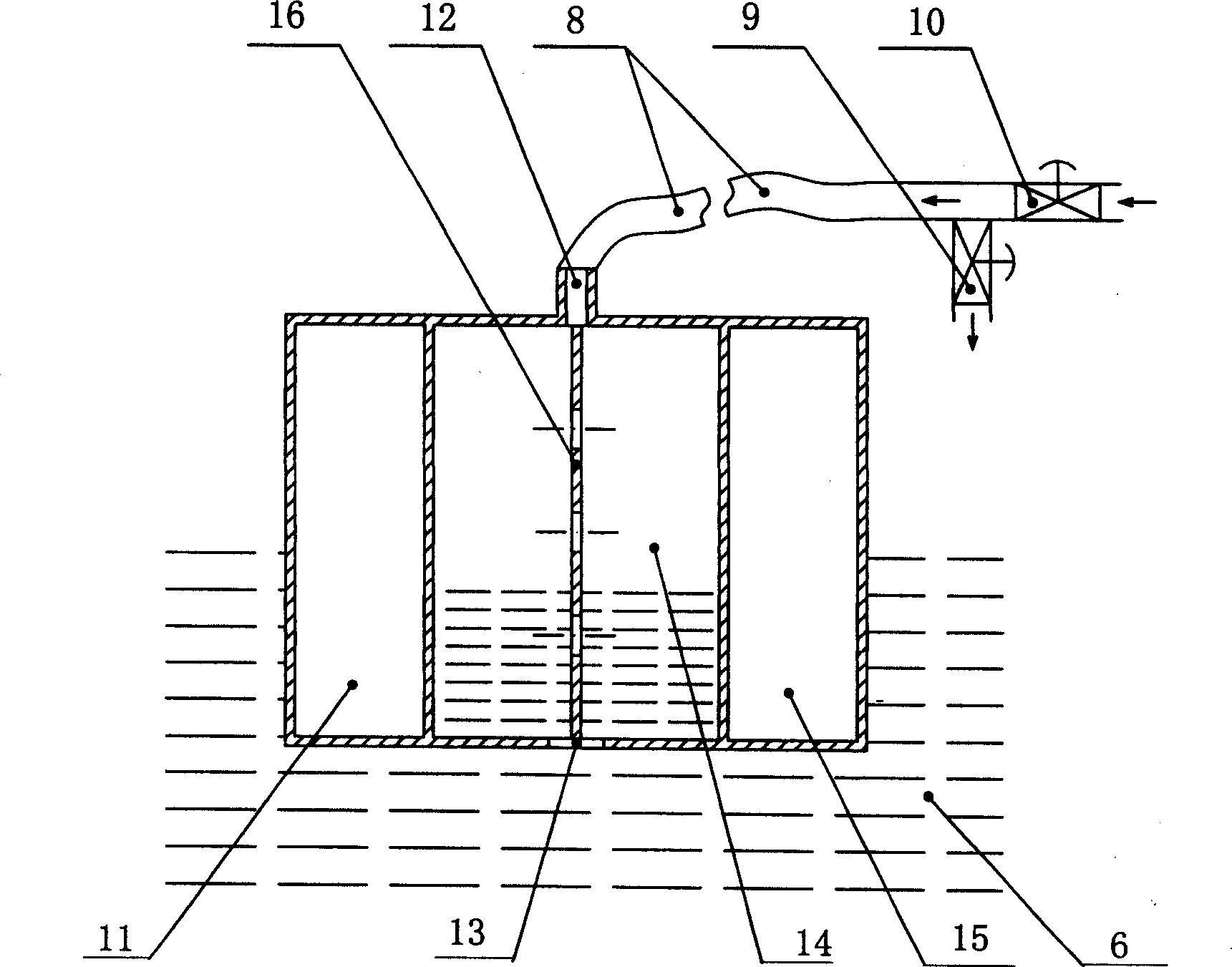

[0017] The structure of the double-toothed roller oil skimmer (see the attached figure 1 ) mainly consists of five parts: a buoyancy box 1, a casing 2, an oil-absorbing surface 3, two toothed rollers 4A and 4B, and drive shafts 5A and 5B. Two buoyancy boxes 1 are symmetrically and balancedly installed on both sides of the casing 2. The buoyancy boxes are used to support all parts of the oil skimmer. The tooth outer surfaces of the gear rollers 4A and 4B are close to the oil-absorbing surface 3, and the oil-absorbing surface 3 is made of wool felt. The oil-absorbing material has a thickness of 30mm; the length of the toothed roller is 1000mm, and the diameter is 500mm; the arc surfaces on both sides of the casing 2 are attached to the outside of the oil-absorbing material at the tooth tip of the two toothed rollers to form a relative seal, and the two toothed rollers The centers of 4A and 4B are respectively connected with drive shafts 5A and 5B to form a static fit, and the dr...

Embodiment 2

[0020] The toothed roller in this embodiment is formed by superimposing a plurality of toothed columnar members. The oil-absorbing surface material on the toothed roller adopts a plurality of small strips of alloy aluminum plates stacked end to end to form a plate chain layer with a thickness of 80 mm. Fastened to the outer surface of the teeth of the toothed roller, the diameter of the toothed roller is 1500 mm, and the length is 2000 mm. The overall structure of the oil skimmer is basically the same as that of Embodiment 1.

Embodiment 3

[0022] The toothed roller of this embodiment is formed by superimposing a plurality of toothed columnar members. The oil-absorbing surface material on the toothed roller is made of a plurality of small stainless steel plates stacked end to end to form a plate chain layer with a thickness of 500 mm. Fastened to the outer surface of the teeth of the toothed roller, the diameter of the toothed roller is 4000 mm, and the length is 5000 mm. The overall structure of the oil skimmer is basically the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com